An optimized mechanical filter

A technology of mechanical filter and liquid separator, which is applied in the direction of gravity filter, loose filter material filter, filtration separation, etc. Avoid problems such as bias flow, so as to avoid the phenomenon of liquid collector breaking or buckle loosening and bias flow, improve the filtration flux, and prevent the effect of bias flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

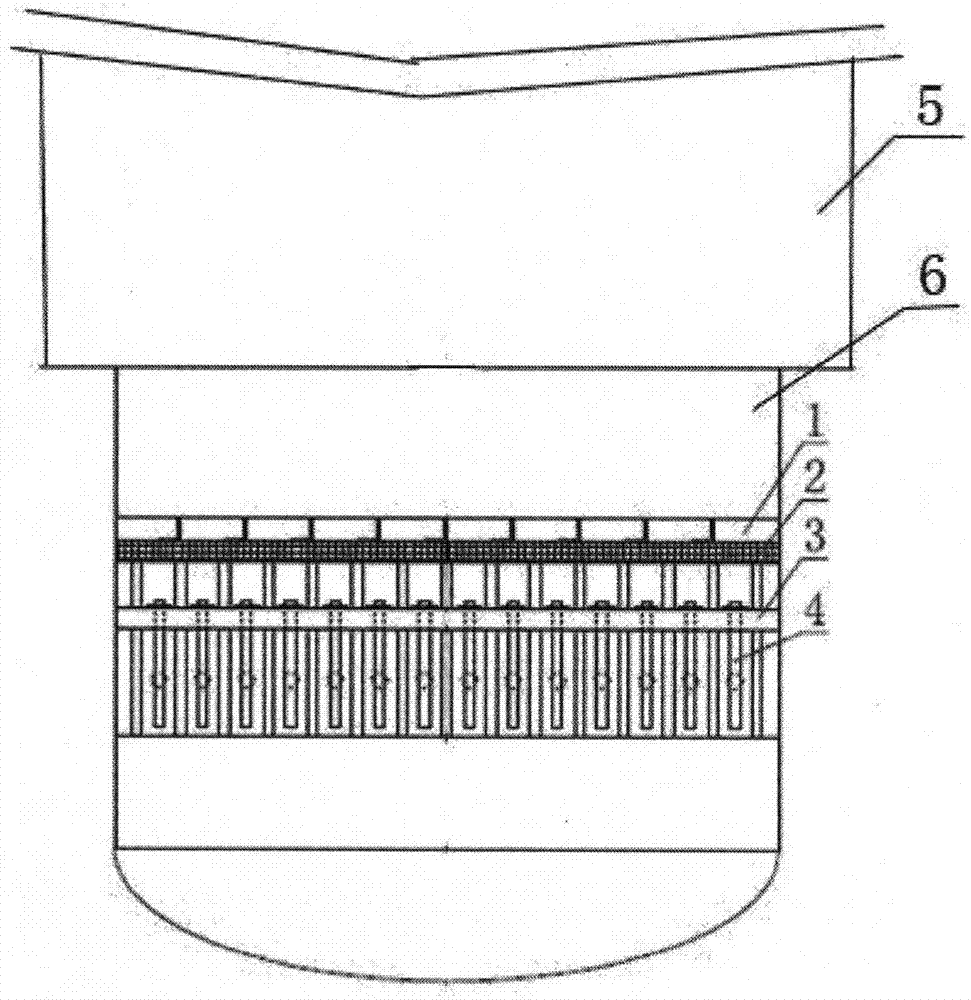

[0015] Such as figure 1 As shown, an optimized mechanical filter includes a cylinder body 5, the upper part of the cylinder body 5 is provided with an inlet, the inlet is provided with a liquid separator, the liquid separator is fixed by a support assembly, the lower part of the cylinder body 5 is provided with an outlet, and the outlet is provided with There is a liquid collector 6, a porous plate 3 is arranged in the liquid collector 6, a filler is arranged on the porous plate 3, several identical water pipes 4 are connected at the outlet, and water pipe holes having the same size as the water pipe 4 are arranged on the porous plate 3, several Two identical water pipes 4 pass through the corresponding water pipe holes on the perforated plate 3, so that the liquid confluence is more relaxed and no strong turbulent disturbance is generated. A water pipe hole stand plate 1 is arranged on the circumference of the upper surface of each water pipe hole, and the water pipes Hole ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com