Si (at) void (at) C embedded three-dimensional porous carbon network negative electrode material and preparation and application thereof

A negative electrode material, three-dimensional porous technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problem of destroying the buffer layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

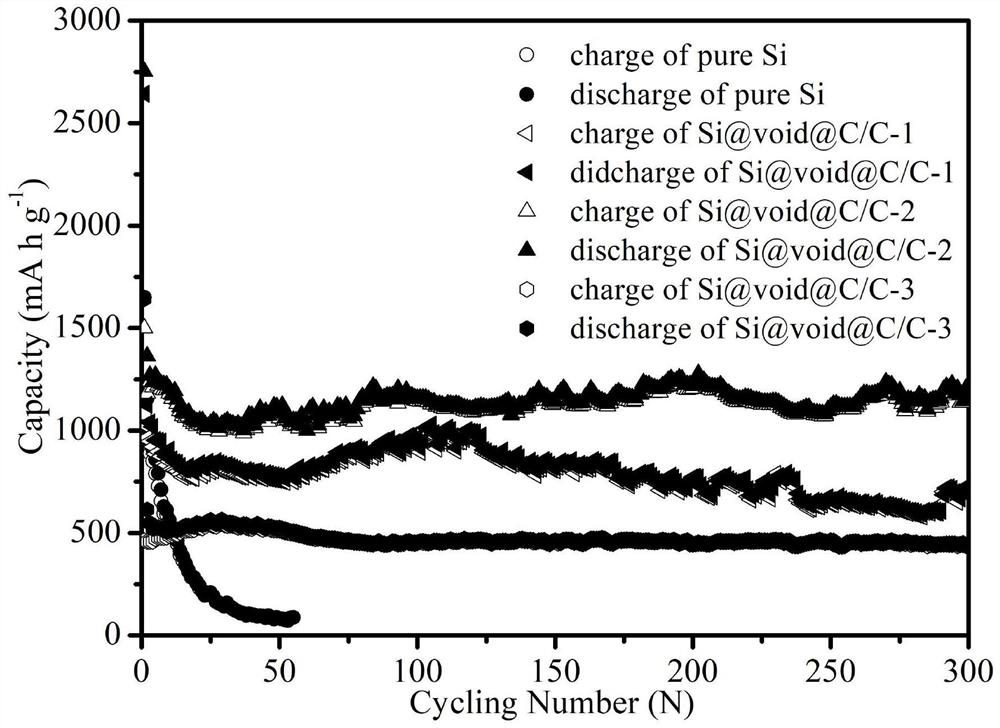

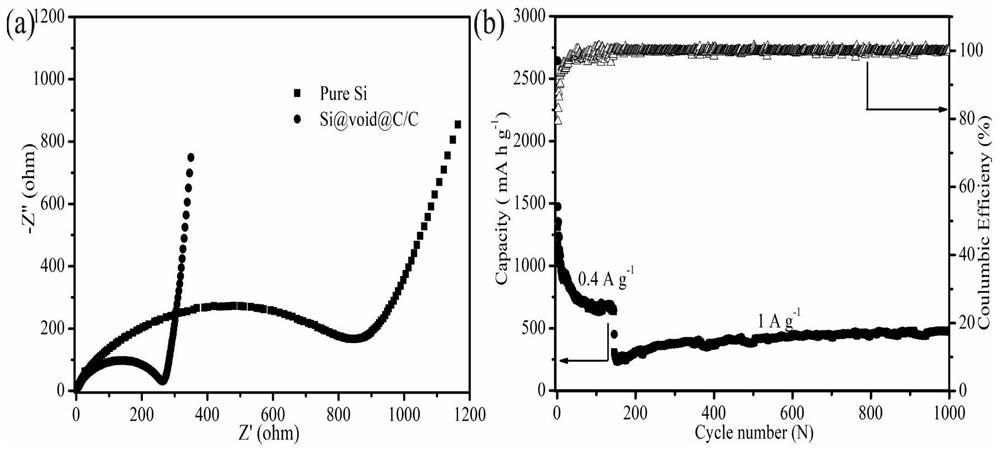

Embodiment 1

[0031] The preparation of Si@void@C / C-1 includes the following steps:

[0032] (1) ultrasonically disperse 60 mg of silicon powder in 12 ml of deionized aqueous solution to obtain silicon powder wrapped in a hydration film;

[0033] (2) Take 0.06ml Tween 80, 0.12ml Span 85 and 40ml styrene monomer as the oil phase, weigh 1.0ml silane coupling agent and 0.045g diphenylphosphine oxide photosensitizer into 40ml oil phase in turn, and stir to obtain Oil phase mixed solution;

[0034] (3) Mix the silicon powder wrapped by the hydration film with the oil phase solution, emulsify and stir for 2 hours, irradiate with ultraviolet light for 1 hour, then vacuum freeze-dry, then send it to Ar gas environment for heat treatment at 850°C for 3 hours, and finally undergo hydrothermal treatment at 160°C 18h to obtain gray-black product.

Embodiment 2

[0036] Preparation of Si@void@C / C-2

[0037] Include the following steps:

[0038] (1) ultrasonically disperse 60 mg of silicon powder in 12 ml of deionized aqueous solution to obtain silicon powder wrapped in a hydration film;

[0039] (2) Take 0.06ml Tween 80, 0.12ml Span 85 and 40ml styrene monomer as the oil phase, weigh 1.0ml silane coupling agent and 0.045g diphenylphosphine oxide photosensitizer into 40ml oil phase in turn, and stir to obtain Oil phase mixed solution;

[0040] (3) Mix the silicon powder wrapped by the hydration film with the oil phase solution, emulsify and stir for 2 hours, irradiate with ultraviolet light for 2 hours, then vacuum freeze-dry, then send it to Ar gas environment for heat treatment at 850°C for 3 hours, and finally undergo hydrothermal treatment at 160°C 18h to obtain gray-black product.

Embodiment 3

[0042] Preparation of Si@void@C / C-3

[0043] Include the following steps:

[0044] (1) ultrasonically disperse 60 mg of silicon powder in 12 ml of deionized aqueous solution to obtain silicon powder wrapped in a hydration film;

[0045] (2) Take 0.06ml Tween 80, 0.12ml Span 85 and 40ml styrene monomer as the oil phase, weigh 1.0ml silane coupling agent and 0.045g diphenylphosphine oxide photosensitizer into 40ml oil phase in turn, and stir to obtain Oil phase mixed solution;

[0046] (3) Mix the silicon powder wrapped by the hydration film with the oil phase solution, emulsify and stir for 2 hours, irradiate with ultraviolet light for 3 hours, then vacuum freeze-dry, then send it to Ar gas environment for heat treatment at 850°C for 3 hours, and finally undergo hydrothermal treatment at 160°C 18h to obtain gray-black product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com