1500MPa ultrahigh-strength low-density steel and preparation method thereof

A technology of ultra-high-strength, low-density steel, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve problems such as low plasticity and poor comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

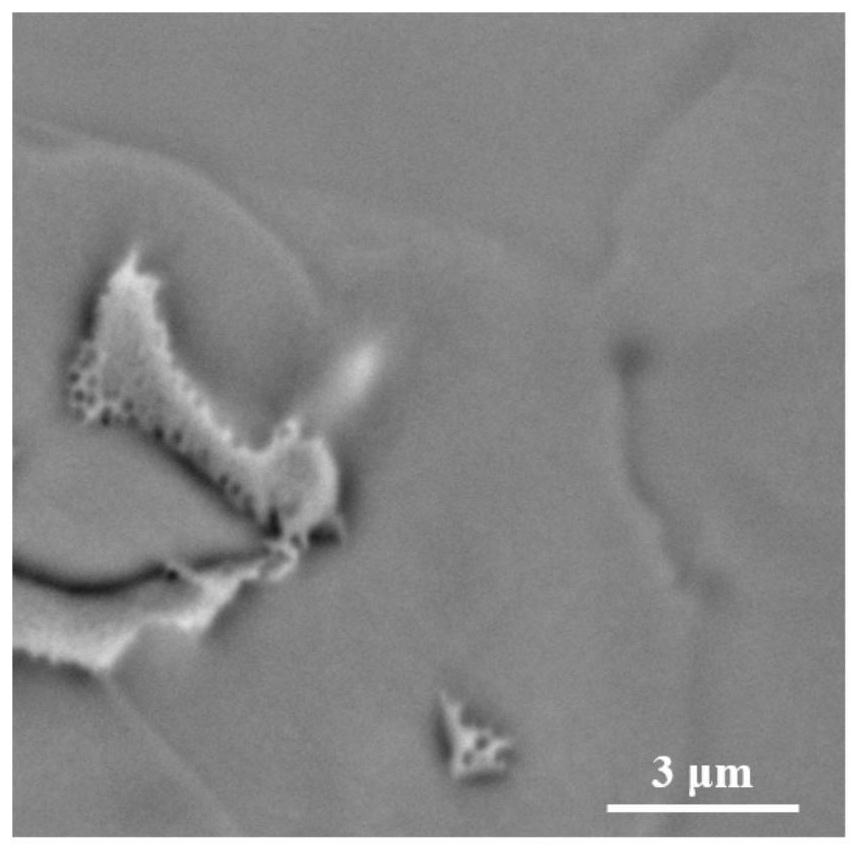

Image

Examples

preparation example Construction

[0037] A method for preparing 1500MPa ultra-high-strength low-density steel as described above, comprising the following steps:

[0038] S1: Melting: mix C, Mn, Al, Cr and Fe according to the mass percentage, clean the ingredients and ultrasonically treat them, then dry them and put them in a vacuum induction suspension melting furnace for melting. Cool after 45min to obtain material ingot;

[0039] S2: Formed plate: heat the ingot to 1500-1600°C, melt the ingot and then perform a sub-rapid solidification forming process to obtain a formed plate. The thickness of the formed plate is 2-3 mm; the cooling rate in the sub-rapid solidification forming process is 10~1000K / s; here it is worth noting that the sub-rapid solidification forming process means that the cooling rate is between 10~10 3 K / s, the principle of sub-rapid solidification is usually achieved by increasing the solidification cooling rate and increasing the degree of solidification supercooling. It is a solidificati...

Embodiment 1

[0044] A 1500MPa ultra-high-strength low-density steel, including the following components in mass percentage: C: 1.39%, Mn: 12.15%, Al: 9.11%, Cr: 3.01%, and the balance is Fe and unavoidable impurity elements in iron. Its preparation method comprises the following steps:

[0045] S1: Melting: Batching C, Mn, Al, Cr and Fe according to the mass percentage, cleaning the ingredients, ultrasonic treatment, drying and melting in a vacuum induction suspension melting furnace, pumping the vacuum induction suspension melting furnace to 0.005 After MPa, the furnace chamber is filled with argon gas with a purity of 99.9% as a protective atmosphere for melting, and it is filled to 0.03Mpa. The heating power of the vacuum induction suspension melting furnace is 28KW~41KW, the heating time is 6~7min, and the melting temperature is 1600~ 1650°C, keep warm for 5 to 45 minutes and then cool to obtain ingots;

[0046] S2: Formed plate: heat the ingot to 1520-1570°C, melt the ingot and put i...

Embodiment 2

[0049] A 1500MPa ultra-high-strength low-density steel, including the following components in mass percentage: C: 1.03%, Mn: 8.17%, Al: 10.87%, Cr: 1.62%, and the balance is Fe and unavoidable impurity elements in iron. Its preparation method comprises the following steps:

[0050] S1: Melting: Batch C, Mn, Al, Cr and Fe according to the mass percentage, clean and ultrasonically treat the ingredients, dry them and put them in a vacuum induction suspension melting furnace for smelting, and pump the vacuum in the induction suspension melting furnace to 0.005 After MPa, the furnace chamber is filled with argon gas with a purity of 99.9% as the smelting protective atmosphere, and it is filled to 0.03Mpa. The heating power of the vacuum induction suspension melting furnace is 28KW~41KW, the heating time is 6~7min, and the melting temperature is 1600~ 1650°C, keep warm for 5 to 45 minutes and then cool to obtain ingots;

[0051] S2: Formed plate: heat the ingot to 1520-1570°C, melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com