Method for inhibiting reaction loss of metallic aluminum in process of extracting aluminum by using aluminum ash wet method

A technology of metal aluminum and aluminum ash, which is applied in the field of aluminum ash recycling, can solve the problems of metal aluminum loss and solution pH increase, and achieve the effects of reducing safety hazards and inhibiting chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

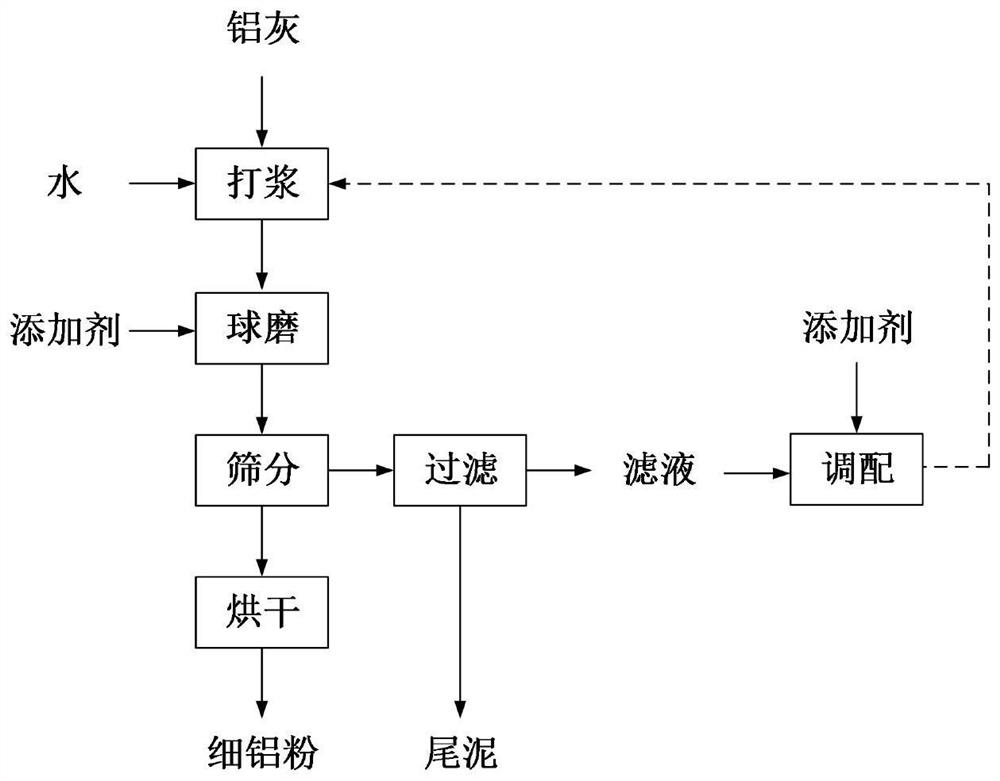

Method used

Image

Examples

Embodiment 1

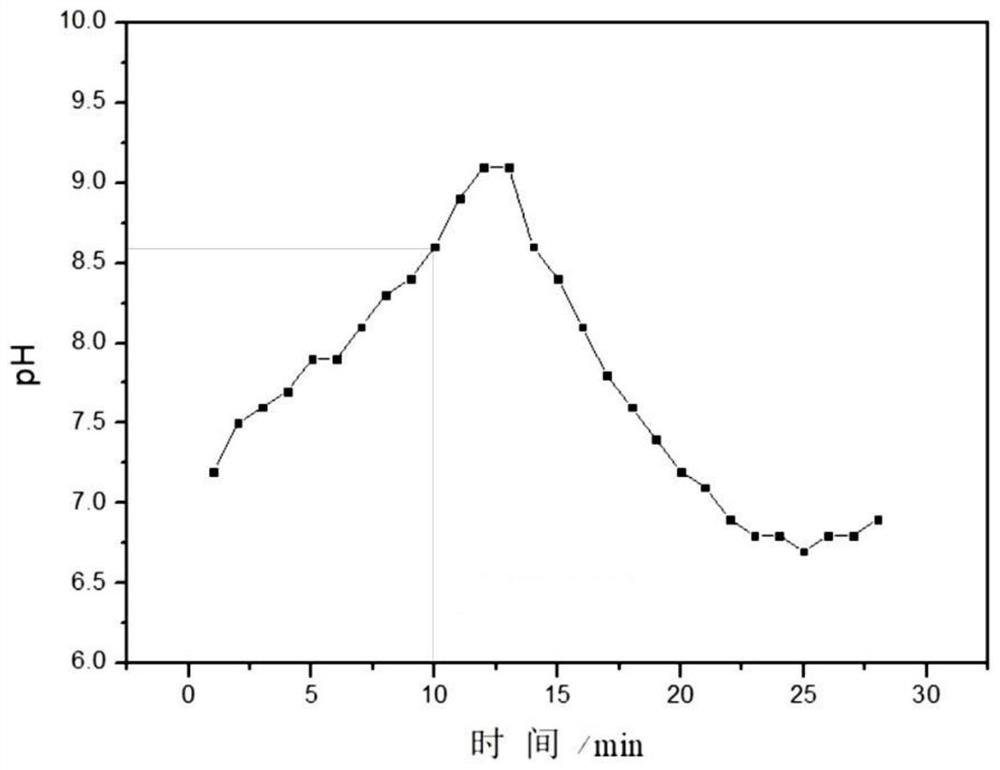

[0034] Primary aluminum ash in a place in Henan was selected as raw material (see Table 1 for specific composition), mixed and beaten according to the mass ratio of aluminum ash and water at a ratio of 1:1, and then the mixed slurry was spirally transported to a ball mill for wet grinding and crushing. The pH of the slurry was measured regularly at the outlet of the ball mill. When the slurry pH > 8.5, slowly add aluminum chloride solid into the ball mill inlet or beating tank, and stop adding aluminum chloride when the slurry pH shows a downward trend. figure 2 As shown; the discharge from the end of the ball mill is conveyed to the feed port of the vibrating sieve by a screw, and the screen is sprayed and washed with water on the upper part of the screen during the screening process, and the above-sieve aluminum powder rich in metal aluminum components and the under-sieve low metal aluminum components are obtained respectively. Slurry, the metal aluminum powder on the sieve...

Embodiment 2

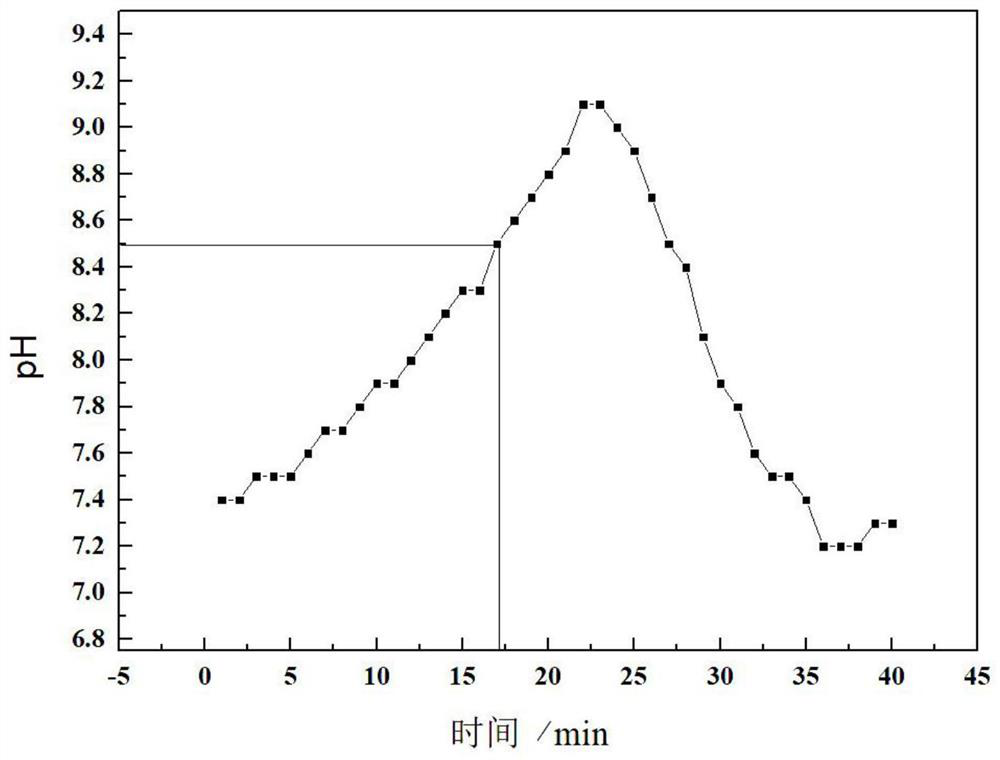

[0041] Primary aluminum ash in a certain place in Henan was selected as the raw material (see Table 1 for the specific composition), mixed and beaten according to the ratio of aluminum ash to water mass ratio of 1:2, and then the mixed slurry was spirally transported to a ball mill for wet grinding and crushing. The pH of the slurry was measured regularly at the outlet of the ball mill. When the slurry pH>8.5, slowly add 5% dilute hydrochloric acid into the ball mill inlet or beating tank, stop adding dilute hydrochloric acid when the slurry pH shows a downward trend, and regularly detect the pH of the ball mill discharge, and ball mill before and after adding additives The change trend of slurry pH value is as follows: image 3As shown, the pH value of the slurry is kept close to neutral; the discharge from the end of the ball mill is conveyed to the feed port of the vibrating screen by a screw, and the screen is sprayed and washed with water on the upper part of the screen d...

Embodiment 3

[0048] The aluminum ash produced by an aluminum processing factory in Gongyi was selected as the raw material, and its metal aluminum content was determined to reach 49.21%. Since it contained many large pieces of aluminum, it was picked out by hand in advance. The remaining aluminum ash and water are mixed and beaten according to the mass ratio of 1:0.8, and then the mixed slurry is poured into a ball mill for ball milling and crushed, and the pH of the slurry is regularly measured at the outlet of the ball mill; when the pH of the slurry is > 8.5 , slowly add 10% dilute acetic acid into the feed port of the ball mill or the beating tank, and stop adding dilute acetic acid when the pH of the slurry shows a downward trend. Spray water on the upper part of the sieve for washing to obtain the over-sieve aluminum powder rich in metallic aluminum components and the under-sieve paddle with low metallic aluminum components. The over-sieved aluminum powder is dehydrated and then sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com