High and low temperature resistant long-life solar photovoltaic backboard and preparation process thereof

A technology of solar photovoltaic and high and low temperature resistance, applied in the field of solar photovoltaic, can solve problems such as unfavorable high and low temperature resistance of solar photovoltaic backplanes, unfavorable production and processing, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

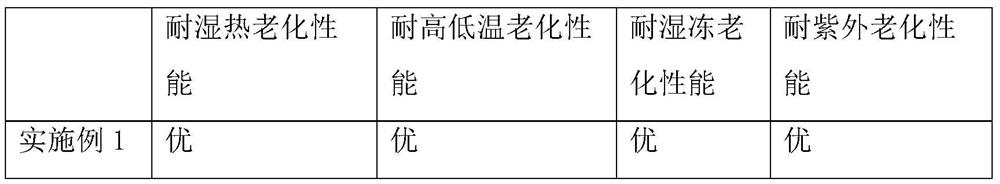

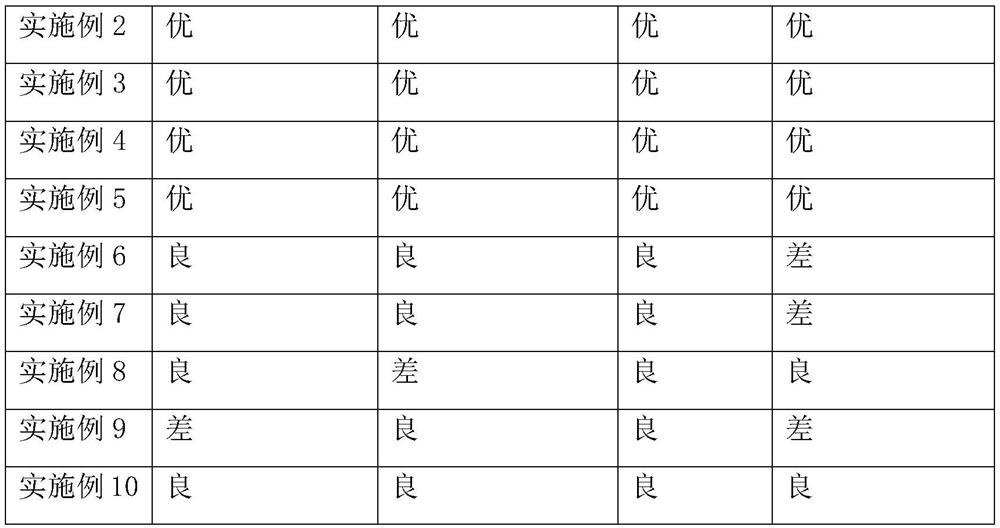

Examples

Embodiment 1

[0048] In order to solve the above technical problems, the first aspect of this embodiment provides a high and low temperature resistant long-life solar photovoltaic backsheet, which at least includes an outer layer and an inner layer connected to the outer layer from top to bottom, and the outer layer The raw materials for preparation of the inner layer, in parts by weight, include 60 parts of the first polyolefin and 5 parts of water-insoluble solid inorganic matter, and the raw materials for the preparation of the inner layer, in parts by weight, include 60 parts of the second polyolefin, 1 part of Sericite and 0.1 part of silane coupling agent, the silane coupling agent is γ-methacryloxypropyltrimethoxysilane, purchased from Dow Corning, product number: KH570.

[0049] The first polyolefin is a mixture of linear low density polyethylene A with a melt index of 1.5-2.5g / 10min, linear low density polyethylene B with a melt index of 21g / 10min, and polypropylene D with a melt in...

Embodiment 2

[0061] In order to solve the above technical problems, the first aspect of this embodiment provides a high and low temperature resistant long-life solar photovoltaic backsheet, which at least includes an outer layer and an inner layer connected to the outer layer from top to bottom, and the outer layer The raw materials for preparing the inner layer include 80 parts by weight of the first polyolefin and 10 parts of water-insoluble solid inorganic matter, and the raw materials for the preparation of the inner layer include 80 parts by weight of the second polyolefin, 3 parts Sericite and 0.3 parts of silane coupling agent, the silane coupling agent is γ-methacryloxypropyltrimethoxysilane, purchased from Dow Corning, product number: KH570.

[0062] The first polyolefin is a mixture of linear low density polyethylene A with a melt index of 1.5-2.5g / 10min, linear low density polyethylene B with a melt index of 21g / 10min, and polypropylene D with a melt index of 16g / 10min, The mass...

Embodiment 3

[0073] The difference between this embodiment and Example 2 is that the first polyolefin in this embodiment is a mixture of low-density polyethylene A, low-density polyethylene B and polypropylene D with a melt index of 16g / 10min. The mass ratio between polyethylene A, low-density polyethylene B and polypropylene D is 1:1:8, the melt index of the low-density polyethylene A is 2.1g / 10min, and the melt index refers to the temperature at 190°C , 2.16kg, obtained by ASTM D-1238 test method, purchased from Shanghai Tangjiu Industrial Co., Ltd., CAS No.: 9002-88-4. The melt index of the low-density polyethylene B is 20g / 10min. The melt index refers to the temperature at 190°C and 2.16kg, obtained by ASTM D-1238 test method, purchased from Shanghai Kaishun Plastic Chemical Co., Ltd., article number: MG200024 ,, the polypropylene D is purchased from Wuxi Xinjiawang Plastic Technology Co., Ltd., the article number is: 6231, the second olefin in this embodiment is a mixture of low densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com