A kind of bolt ball for steel structure connection

A technology of steel structure and bolt ball, which is applied in the direction of building structure and construction, can solve the problems of poor firmness and stability of the connection structure, and achieve the effect of improving firmness, strength, and contact force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

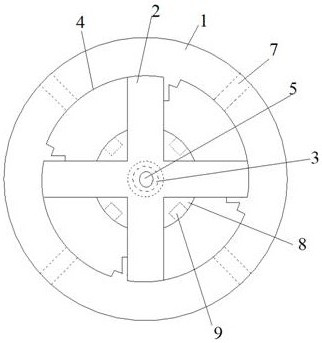

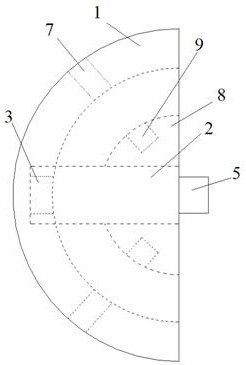

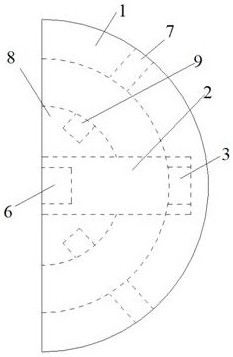

[0020] A kind of bolt ball for steel structure connection, see figure 1 , the bolt ball for steel structure connection includes two hemispherical shells 1, the hemispherical shells 1 are provided with "ten" shaped reinforcing ribs 2, the inner ends of the reinforcing ribs 2 are provided with connecting screws 3, the ends of the hemispherical shells 1 Connecting screw holes are provided at the connecting screw rod 3 on the inner wall of the part, and four horizontal "L"-shaped arcuate grooves 4 are evenly distributed on the inner side wall of the hemispherical shell 1, and the circumferential direction of the arcuate surface groove 4 The groove surfaces are all arc-shaped surfaces, the radial groove surface of the arc-shaped groove 4 is a plane, and the circumferential side walls of the four rib plates of the reinforcing rib 2 are all set as arc-shaped surfaces matching the circumferential groove surfaces; see figure 2 , one of the hemispherical shells 1 is provided with a rai...

Embodiment 2

[0024] A kind of bolt ball for steel structure connection, similar to embodiment 1, the difference is, see Figure 4 , The cross-section of the corner post 8 is a right-angle sector. This can facilitate the joint connection between the corner post 8 and the "cross" shaped reinforcing rib 2.

[0025] preferred, see Figure 4 , the two sides of the corner post 8 are respectively connected with connecting plates 10, and the connecting plates 10 are respectively in contact with the side walls of the ribs. This can facilitate the connection of the corner post 8 with the rib plate through the connecting plate 10 . The connecting plate 10 can be connected to the corner post 8 through a bolt structure or a welding structure, and the connecting plate 10 and the corner post 8 can also be provided as an integrated structure.

[0026] Preferably, the connecting plate 10 and the rib plate are configured as metal parts connected by a welding structure.

[0027] preferred, see Figure 4 ,...

Embodiment 3

[0031] A kind of bolt ball for steel structure connection, similar to embodiment 1, the difference is, see Figure 5 , the circumferential groove surface of the arc groove 4 is an inclined arc surface. That is, if point a is taken on the circumferential groove surface of the arc groove 4, then the intersection point of the extension line of point a and the perpendicular to the central axis of the reinforcing rib 2 and the outer wall of the hemispherical shell 1 is point b, then the arc surface is made through point a The tangent line L1 of the circumferential groove surface of the groove 4 is the tangent line L2 of the outer wall of the hemispherical shell 1 through point b, and the angle between the tangent line L1 and the tangent line L2 is greater than 0° and less than 90°. In this way, the firm performance of the combined connection structure between the rib 2 and the hemispherical shell 1 can be further improved.

[0032] Preferably, the four circumferential side walls o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com