Cellulose/nano inorganic filler composite gel ink for 3D printing and preparation method of cellulose/nano inorganic filler composite gel ink

A nano-inorganic filler and composite gel technology, applied in the field of preparation of 3D printing gel ink, can solve the problems of environmental protection hazards, high energy consumption, strict requirements for printing ink forming conditions, etc., and achieve good biocompatibility, The effect of a wide range of sources and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

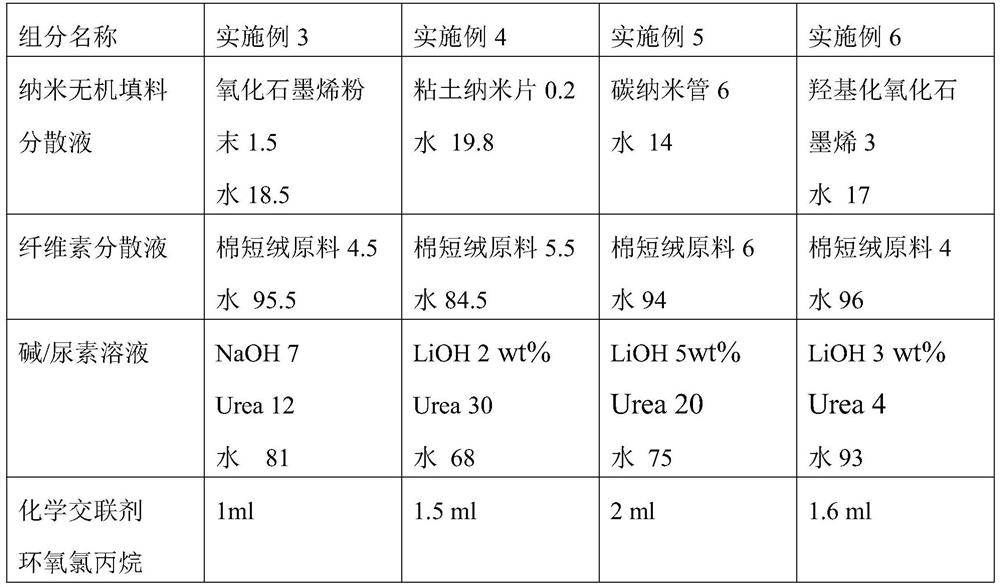

[0031] The 3D printing cellulose / nano-inorganic filler composite gel ink provided by the present invention is a cellulose-based composite gel aqueous solution with nano-inorganic materials as fillers and cellulose as a polymer matrix. According to the ratio of parts by mass, It is made of 15-20 parts of nano-inorganic filler dispersion, 90-100 parts of cellulose dispersion, and 1-2 parts of chemical crosslinking agent; the addition amount of nano-inorganic filler in the nano-inorganic filler dispersion is 1-30 wt%, The added amount of fiber in the cellulose dispersion is 4-6 wt%.

[0032] The nano-inorganic filler is one of graphene oxide nanosheets, clay nanosheets, and carbon nanotubes; the cellulose raw material is cotton linters; the chemical crosslinking agent is epichlorohydrin; the ink is When the preparation is completed, it is partially cross-linked; when in use, the ink is soaked in deionized water at 50°C-100°C, and fully cross-linked by thermal induction, then it c...

specific Embodiment 1

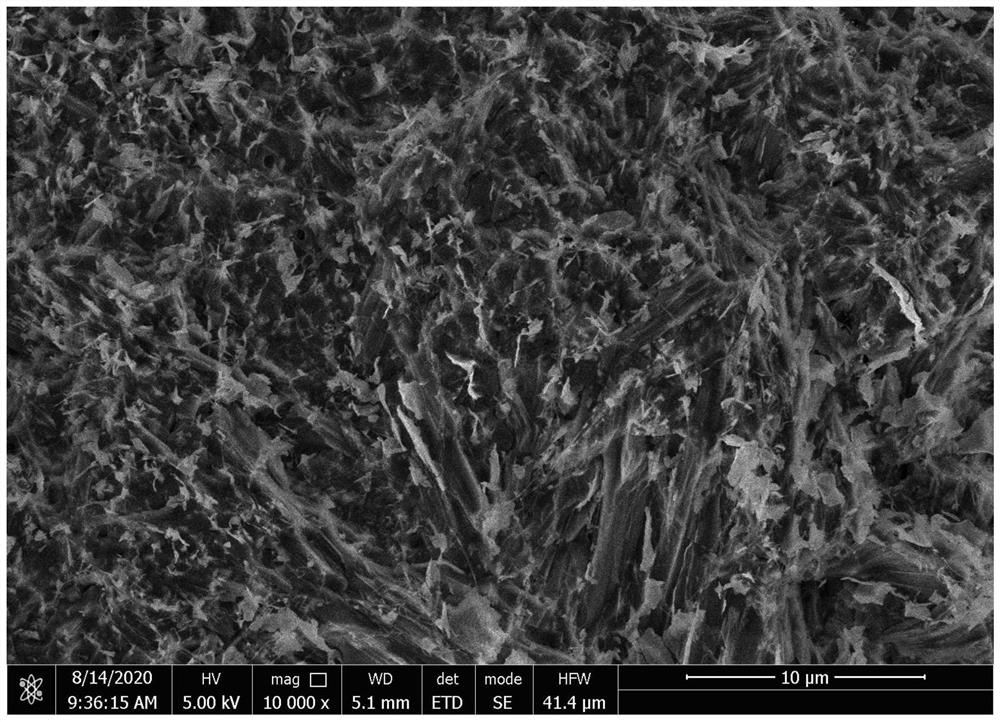

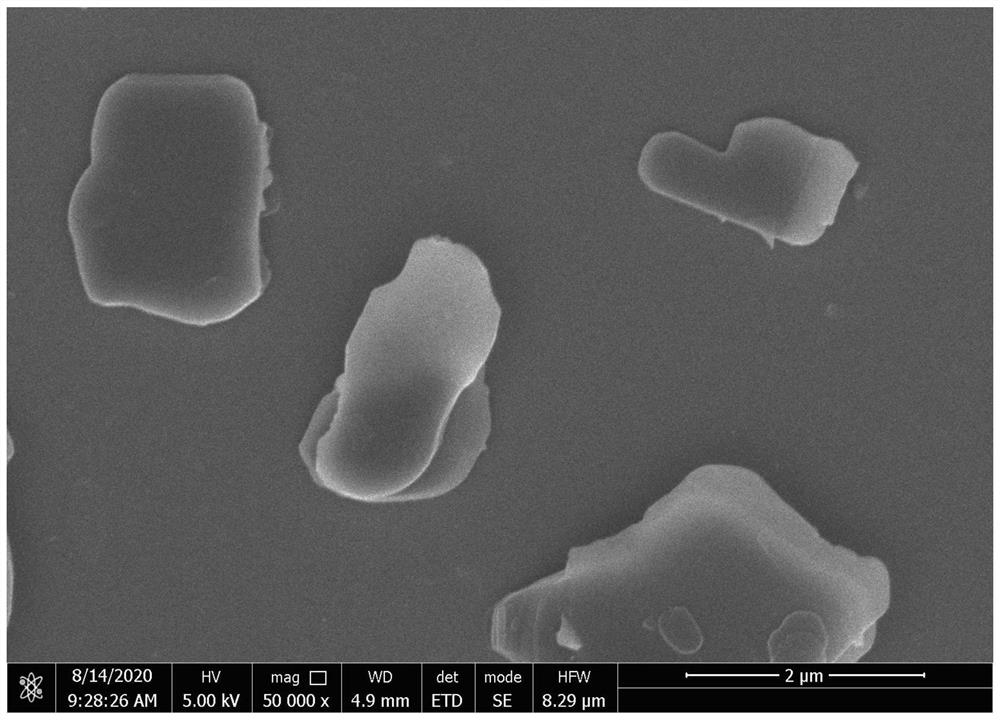

[0044] See attached Figure 1~2 , the 3D printing cellulose / nano-inorganic filler composite gel ink provided in this example uses hydroxylated graphene oxide as the nano-inorganic filler.

[0045] A kind of preparation method of the cellulose / graphene composite gel ink that is used for 3D printing nano composite material, it comprises the following steps:

[0046] (1) Add a quantitative amount of hydroxylated graphene oxide into deionized water, and ultrasonically disperse to obtain a uniformly dispersed graphene oxide dispersion; for the graphene oxide ultrasonic dispersion process, the ultrasonic power is 20W-80W, and the ultrasonic time is 1h-12h ;

[0047] (2) Take a quantitative amount of cotton linter raw material, add alkali / urea solution pre-cooled to a specified temperature, and stir rapidly to obtain a cellulose dispersion; add the graphene oxide dispersion obtained in the above step (1) to the fiber In the plain dispersion, stir vigorously to obtain a mixed disper...

specific Embodiment 2

[0062] The preparation method of the cellulose / graphene composite gel ink for 3D printing nanocomposite provided by the embodiment of the present invention comprises the following steps:

[0063] (1) Add 1.0 g of graphene oxide powder into 19.0 g of deionized water, and ultrasonicate for 30 min at a power of 80 W to obtain a graphene oxide dispersion;

[0064] (2) Weigh 4.5g of dried cotton linter raw material, add it into 75.5g of 7wt%NaOH / 20wt%urea solution precooled to -10°C, and stir rapidly for 5min to obtain a cellulose dispersion;

[0065] (3) the graphene oxide dispersion liquid and the cellulose dispersion liquid that above-mentioned step (1) and step (2) obtain are mixed, under ice-bath condition, carry out mechanical stirring with the rotating speed of 1000r / min;

[0066] (4) Under the stirring condition of the above step (3), slowly add 1 mL of the chemical crosslinking agent epichlorohydrin, and the stirring time in the ice bath is 30 min;

[0067] (5) Take the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com