Lithium ion battery nickel-cobalt-doped lithium manganate positive electrode material and preparation method thereof

A lithium-ion battery and lithium heteromanganate technology, which is applied in the field of nickel-cobalt-doped lithium manganate cathode material and its preparation for lithium-ion batteries, can solve the problems of poor consistency of cathode materials, high reaction energy consumption, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

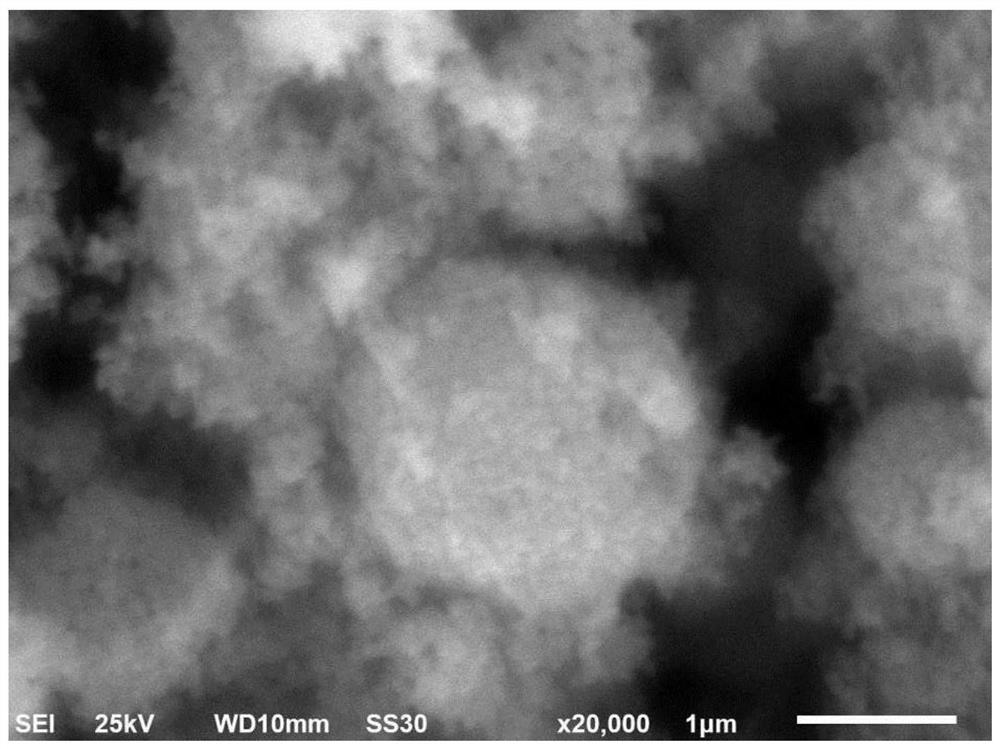

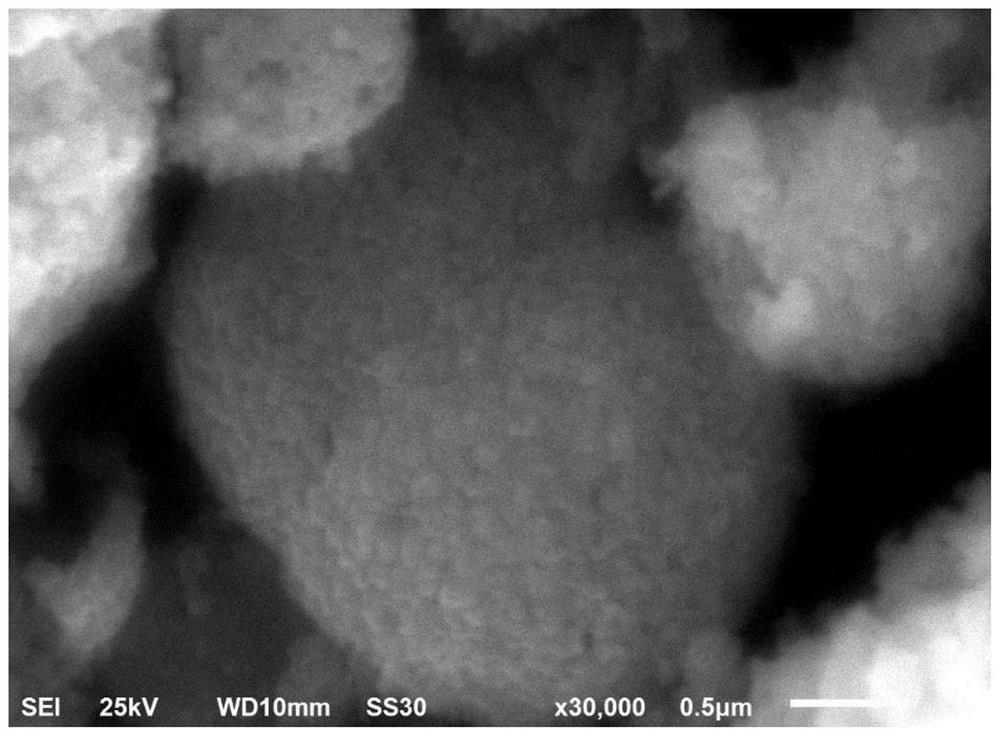

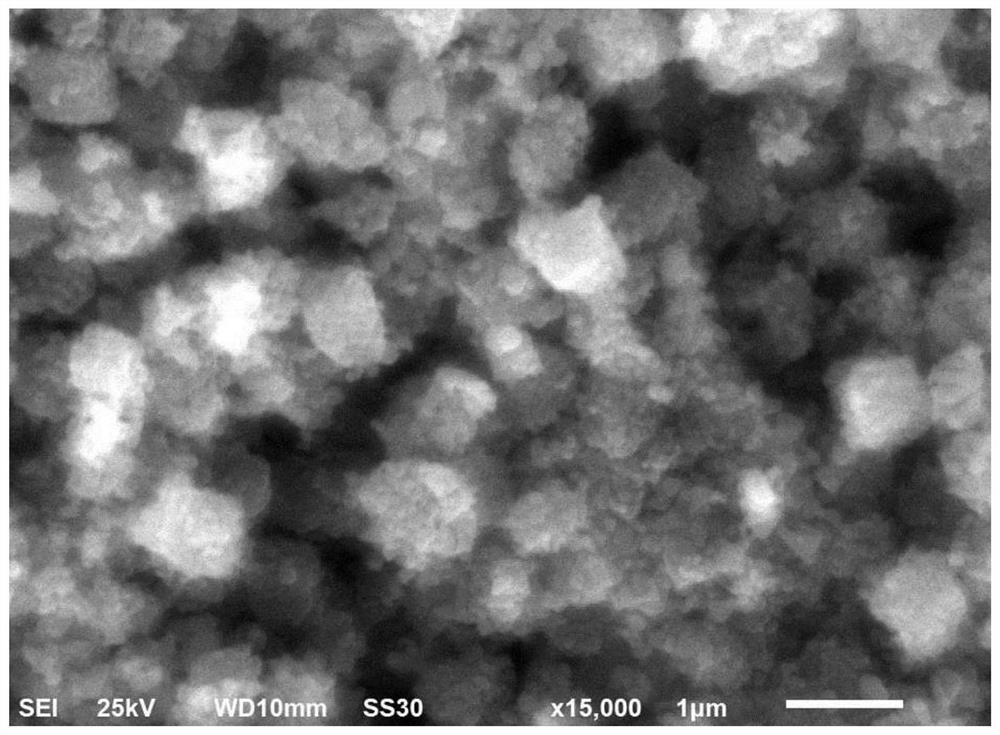

Image

Examples

Embodiment 1

[0052]A lithium ion battery nickel-cobalt doping with amylated positive electrode material, the specific steps of its preparation are:

[0053]A, 0.8 mole of manganese sulfate, 0.15 mole nickel, 0.05 mole of cobalt, 1.02 mole LiOH, 0.25 mole to potassium sulfate mix, ground or ball milling is formed into a reaction mixture, transfer mixture to the polytetrafluoroethylene liner. Stainless steel reactor;

[0054]B, stir, to 20 g of surfactant CTAB, 250 ml of distilled water, 100 mL surfactant aid isopentyl alcohol, 150 ml of cyclohexane, is made into transparent or translucent microemulsion;

[0055]C, add the microemulsion of the B step to the reaction kettle of the A step, mix uniform, sealed, and reacted in an oven at 55 ° C for 12 hours, cooling;

[0056]D, remove the mixture after the C step reaction, filtrate, and filter the solid with 500 ml of 95 wt% alcohol was washed once, then washed with distilled water to detect the sulfate, dried 65 ° C, i.e., lithium-cobalt-doped manganese acid Pos...

Embodiment 2

[0059]A lithium ion battery nickel-cobalt doping with amylated positive electrode material, the specific steps of its preparation are:

[0060]A, 0.4 mole nitrate, 0.4 manganese acid manganese, 0.075 mole sulfate, 0.075 mole acetate, 0.025 mole nitrite, 0.025 mole of cobalt, 0.255 mole Li2O, 0.52 lithium acetate and 0.35 molar sodium sulfate mixture, sufficiently polished or balls into reaction mixture, transfer mixture to the stainless steel reactor of the polytetrafluoroethylene liner;

[0061]B, stir, in 18 g of surfactant SDS, 220 mL of deionized water, 80 mL of surfactant censoon n-butanol, 130 ml of n-heptane, and made microemulsion transparent or translucent;

[0062]C, add the microemulsion of the B step to the reaction kettle of the A step, mix uniform, sealed, and reacted in an oven at 60 ° C for 16 hours, cooling;

[0063]D, remove the mixture after the C step reaction, filtrate, and filter solid was washed with 600 ml of no water, then washed with distilled water to detect the sulfu...

Embodiment 3

[0066]A lithium ion battery nickel-cobalt doping with amylated positive electrode material, the specific steps of its preparation are:

[0067]A, 0.35 mole of manganese, 0.35 acetate, 0.2 mole nickel nickel nickel, 0.1 mole acetate, 0.25 moles of lithium sulfate, 0.54 moles of lithium nitrate, and 0.45 mole of ammonium sulfate is mixed sufficiently polished or ball mills to reactive mixture, transfer mixture transfer In the stainless steel reactor of the polytetrafluoroethylene liner;

[0068]B, stir, 16 g of surfactant ABS, in turn with 200 ml of distilled water, 60 mL surfactant aid pentanol, 120 ml of octane, is made into a transparent or translucent microemulsion;

[0069]C, add the microemulsion of the B step to the reaction kettle of the A step, mix uniform, sealed, and reacted in an oven at 65 ° C for 20 hours, cooling;

[0070]D. Remove the mixture after the C step reaction, filtrate, filter solids 800ml, 95% alcohol eluting, then washed with distilled water to detect the sulfuric acid,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com