Reciprocating type high-temperature synthesizing device

A synthesis device and reciprocating technology, which is applied in the field of reciprocating high-temperature solid-phase synthesis devices, can solve the problems of easy aging of sealing rings, affecting product purity, and affecting synthesis efficiency, etc., to achieve extended life, improved synthesis efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

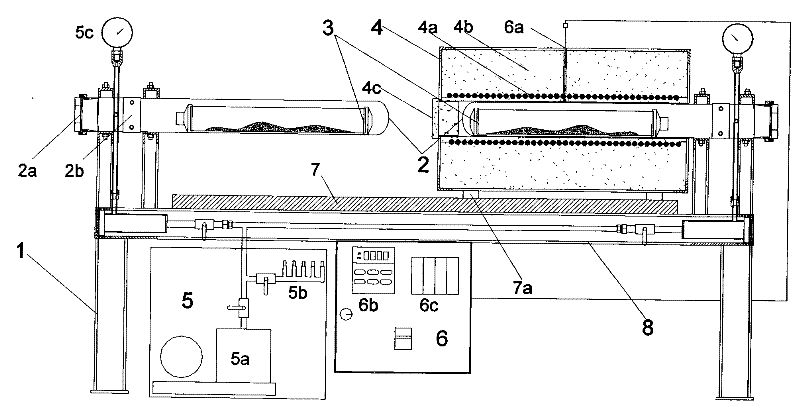

[0015] As shown in the drawings, the present invention installs a workbench 8 on the left and right steel frames 1, and a guide rail 7 is installed on the workbench. The bottom slider 7a of the hollow heating furnace 4 is installed on the guide rail 7, and the heating furnace 4 can be mounted on the guide rail 7. The upper part reciprocates left and right, the two ends of the worktable 8 are equipped with the support frame of the furnace tube 2 respectively, the two furnace tubes 2 with the same structure are respectively provided with a dismountable reaction tube 3, and the outer outlet ends of the two furnace tubes 2 A sealing flange 2a with a rubber sealing ring is installed. A water-cooled jacket 2b is welded to the outside of the furnace tube 2 close to the sealing end. A vacuum pipe is installed in the workbench 8. The two ends of the vacuum pipe pass through the valve and the respective furnace pipe 2 respectively. The two furnace tubes 2 are connected with a vacuum press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com