A nanocrystalline soft magnetic alloy melting system

A nanocrystalline soft magnetic and alloy technology, which is applied in the direction of electric furnace heating, furnace, furnace type, etc., can solve the problems of easy burning, water leakage, poor sealing, and short service life of electrode sealing rings, and achieves convenient disassembly, installation, and The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The first embodiment of the present invention provides a method for preparing a nanocrystalline soft magnetic alloy material, which includes the following steps 1 to 5:

[0045] Step 1: Ingredients

[0046] a. Configure and mix iron, silicon, boron, niobium, copper, cobalt, and nickel as raw materials according to the required atomic percentage of each component;

[0047] Step 2: Master alloy smelting

[0048] a. Place the prepared raw materials in the electric arc furnace;

[0049] b. Vacuum in the electric arc furnace, the vacuum degree is 6.67*10 -3 Pa (electric arc furnace power 1600kw / h, voltage 10kv, frequency 2000Hz), and filled with argon gas with a purity of 99.99%;

[0050] c. Melting and cooling the raw materials in an argon environment, and repeating this for 3 to 5 times, finally obtaining a master alloy ingot;

[0051] Step 3: Master alloy ingot pretreatment

[0052] a. Breaking the master alloy ingot to form small pieces;

[0053] b. Put the broken ...

Embodiment 2

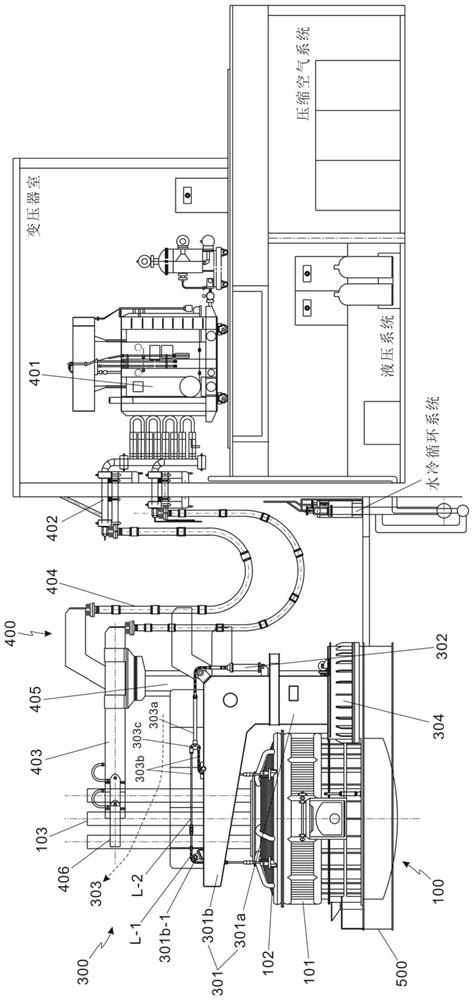

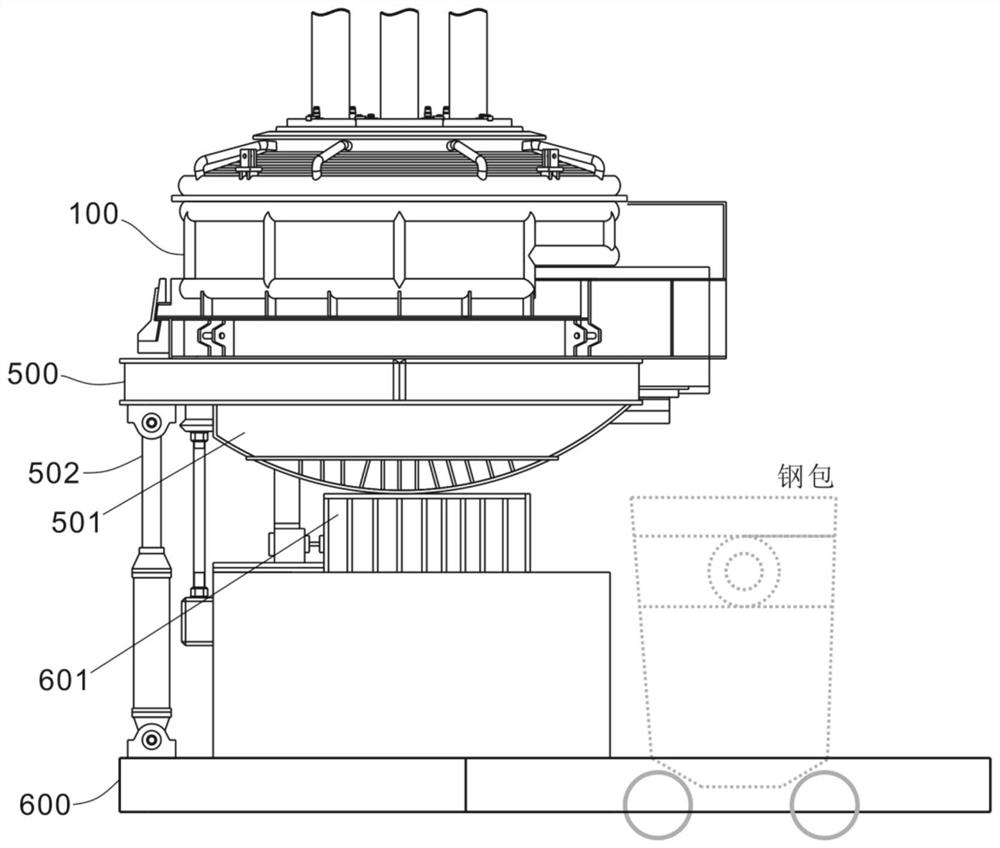

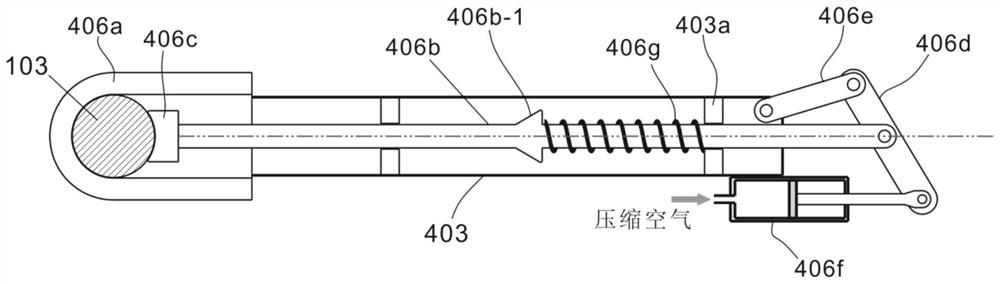

[0063] Such as Figure 1-7 , the "Master Alloy Melting" step in Example 1 is completed by using a nanocrystalline soft magnetic alloy melting system of the present invention, which has high processing efficiency, and the composition of the master alloy after melting can be accurate to the PPM level. In addition, the electrode and its sealing ring, which are the core components on the melting system, are also easy to install.

[0064] The nanocrystalline soft magnetic alloy smelting system includes a smelting unit 100 , a water-cooled sealing unit 200 , a furnace cover lifting control unit 300 , and a power transmission unit 400 .

[0065] The smelting unit 100 includes a furnace body 101 , a furnace cover 102 covering the top of the furnace body 101 , and three electrodes 103 passing through the furnace cover 102 .

[0066] The furnace cover 102 is provided with three electrode holes 102 a corresponding to the electrodes 103 , and the three electrode holes 102 a are distribut...

Embodiment 3

[0098] Such as Figure 8-14 , this embodiment is different from the previous embodiment in that: the water-cooled sealing unit 200 in this embodiment adopts a stacked assembled structure, which combines the respective advantages of the existing annular water tank type and serpentine tube type electrode sealing rings , and can be installed and replaced on site very conveniently.

[0099] The water-cooling sealing unit 200 includes a plurality of C-shaped sealing rings 201 stacked, and a tightening member 202 capable of tightening and fixing each C-shaped sealing ring 201 to form a whole.

[0100] Specifically, the main body of each C-shaped sealing ring 201 is a C-shaped structure, and a bayonet K with one side opening is formed at the center, the inner diameter of which matches the outer diameter of the electrode 103, and the outer diameter matches the inner diameter of the electrode hole 102a.

[0101] Each C-shaped sealing ring 201 has a C-shaped chamber 201a inside, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com