Method for removing boron ions in fracturing flow-back fluid

A fracturing flowback fluid, boron ion technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Achieve the effect of good stability, easy operation and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

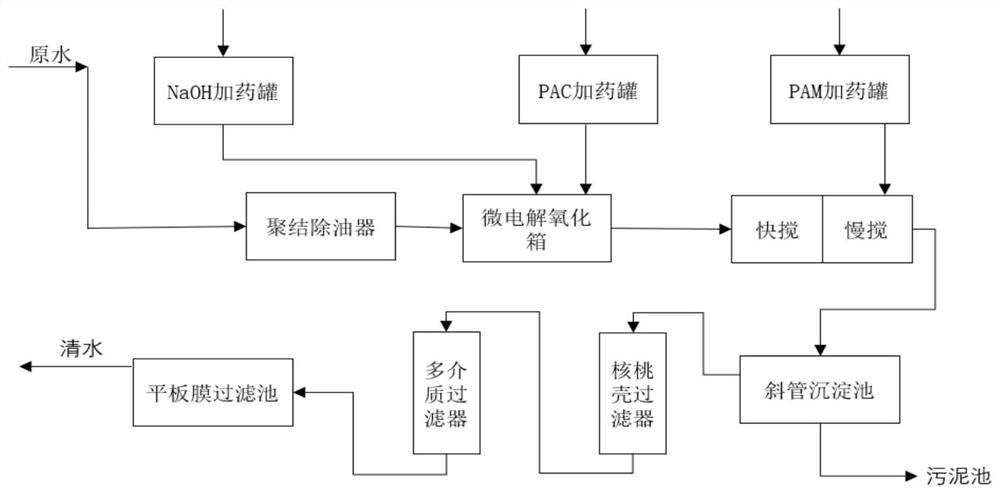

[0054] This test was carried out in an oilfield in Ordos, and the processing capacity of the equipment was 20m 3 / h. The technological process of boron removal by chemical agents is as follows: figure 2 shown.

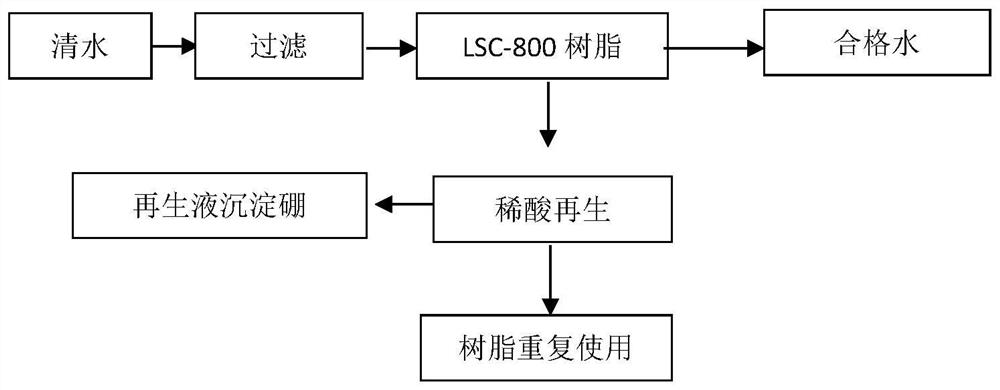

[0055] The clear water after the above technological process is processed is then treated with a boron removal device. The specific technological process is as follows: image 3 shown.

[0056] see figure 2 and image 3 , the specific process flow is: the raw water first enters the coalescing degreasing device, and the function of the coalescing degreasing device is coarse-grained degreasing. Under the action, the oil droplets will change from small to large, float to the water surface, and be discharged into the oil collection tank through the oil discharge pipe.

[0057] The water coming out of the coalescing degreasing device flows into the micro-electrolytic oxidation device by itself, and through the electrochemical reaction generated by the potential diff...

Embodiment 2

[0065] Measure 500mL of fracturing flowback fluid taken from Field Well-2 into a beaker, the boron content in it is 17.36mg / L measured by curcumin spectrophotometry, and the calcium ion content measured by titration method is 310.23mg / L , the content of suspended solids was 170.66mg / L. The dosage of each agent is determined according to the measured ion content.

[0066] First add oxidant sodium hypochlorite solution (mass concentration is 0.1%) in the sodium hydroxide dosing box, its addition is 0.08% of guar gum fracturing flowback liquid quality to carry out, add calcium magnesium ion precipitant sodium carbonate subsequently, it adds The amount is carried out according to the molar ratio of calcium and magnesium ions in the flow-back liquid at 1:1, and the pH of the solution is adjusted to 9.5 with a 4% sodium hydroxide aqueous solution, and the reaction is carried out at room temperature for 12 minutes. Then add the prepared inorganic flocculant polyaluminum chloride sol...

Embodiment 3

[0069] Measure 500mL of the fracturing flowback fluid retrieved from Field Well-3 into a beaker. The boron content in it is 19.65mg / L as measured by curcumin spectrophotometry, and the calcium ion content as measured by titration is 1000.5mg / L. L, the content of suspended matter is 230.6mg / L. The dosage of each agent is determined according to the measured ion content.

[0070] First add oxidant hydrogen peroxide (mass concentration is 0.1%) in the sodium hydroxide dosing box, its addition is 0.1% of the guar gum fracturing flowback liquid quality to carry out, then add calcium and magnesium ion precipitant sodium sulfate, its addition According to the molar ratio of calcium and magnesium ions in the flowback liquid to 1:1, the pH of the solution was adjusted to 10 with a 4% aqueous sodium hydroxide solution, and the reaction was carried out at room temperature for 8 minutes. Then add the prepared inorganic flocculant polyaluminum chloride solution into the PAC dosing box, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com