A hydrogen fuel cell system based on power plant waste heat

A fuel cell system and power plant waste heat technology, which is applied in the field of thermal power plants, can solve problems such as difficult coordination of temperature gradients, and achieve the effects of improving energy utilization, high energy comprehensive utilization efficiency, and eliminating self-consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments.

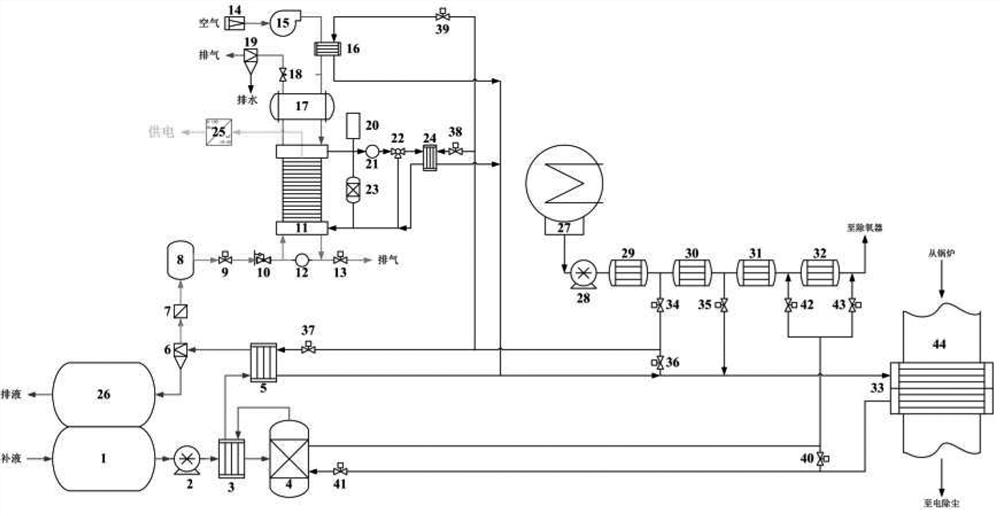

[0018] Take a 600MW coal-fired generating set as an example. refer to figure 1 As shown, the present invention discloses a hydrogen fuel cell system based on low-pressure economizer of power plant and organic liquid hydrogen storage technology, including hydrogen fuel cell system and low-pressure economizer system.

[0019] The hydrogen fuel cell system includes a hydrogen subsystem, an air subsystem, a circulating water subsystem and a power generation subsystem.

[0020] The hydrogen subsystem includes a hydrogen-rich organic liquid storage tank 1, a metering pump 2, a cold side of a preheater 3, a dehydrogenation reactor 4, a hot side of a preheater 3, a cooler 5, and a steam-water separation tank connected sequentially by connecting pipes. Device 6, filter 7, buffer tank 8, solenoid valve 9, pressure reducing valve 10, hydrogen fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com