Preparation method of magnetic powder particle transmission electron microscope sample

A technology of transmission electron microscope samples and powder particles, which is applied in the preparation of test samples, the application of conductive/insulating/magnetic materials on magnetic films, the magnetism of inorganic materials, etc., and can solve problems such as cutting powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

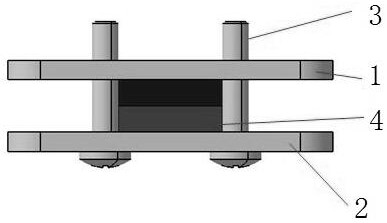

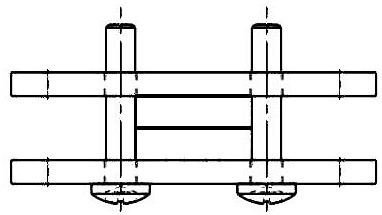

[0026] like Figure 1-Figure 7 As shown, the clamp includes a fixture upper end fixing piece 1 , a fixture lower end fixing piece 2 , a bolt 3 and a pressure block 4 . The fixed piece 1 at the upper end of the fixture and the fixed piece 2 at the lower end of the fixture are square pieces with a side length of 50 mm and a thickness of 3 mm. The four corners are formed with arcs with a radian of 5, and the corresponding positions 10 mm away from the central axis are equidistant. There are four bolt holes with a diameter of 4.5 mm. Bolts 3 are provided in the bolt holes. The upper end of the fixture 1 and the lower end of the fixture 2 are adjusted by bolts 3. The pressure block 4 is placed on the upper end of the fixture for fixation. Between sheet 1 and fixed sheet 2 at the lower end of the fixture, the pressurized block is a square block with a side length of 16 mm and a thickness of 4 mm.

[0027]Spread the magnetic powder particles on the TEM sample support net and add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com