Mutual-nested topology pipeline type structure and overall forming method

An integral molding and pipeline technology, applied in branch pipelines, pipes, tubular articles, etc., can solve problems such as difficulty in forming composite materials, and achieve the effect of ensuring integrity and improving structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

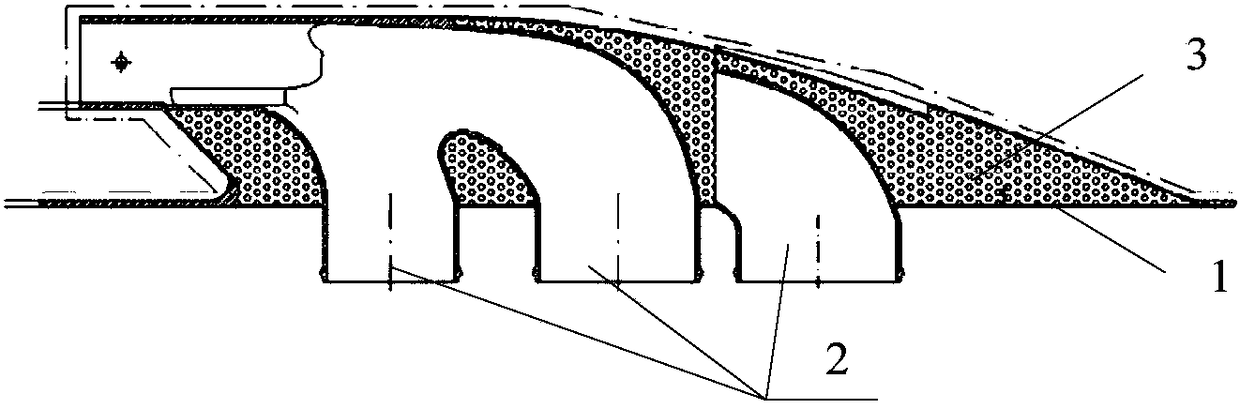

[0037] Composite materials are used instead of figure 1 The metal materials are nested with complex topological piping structures, and composite materials are nested with complex topological piping structures, such as figure 2 , 3 As shown, it includes an inner composite topological pipeline 2, an outer composite shell 1 and a dimensional core material 3 between the inner composite topological pipeline and the outer composite shell. The wall thickness of the internal pipeline is 2mm, the wall thickness of the outer shell is divided into two thickness areas of 1mm and 3mm, the inner diameter of the main pipe is divided into two specifications: Φ76mm and Φ62mm, and the main body length is about 584mm.

[0038] The specific preparation process is as Figure 4 shown in the following steps:

[0039] 1. Single pipeline soluble mandrel

[0040] Place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com