A real-time optimal control system and method for a continuous catalytic reforming unit

A catalytic reforming and optimal control technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as high production costs and large gaps in economic benefits, and achieve the goal of improving product yield and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107] The present invention will be further analyzed below in conjunction with the accompanying drawings and specific embodiments.

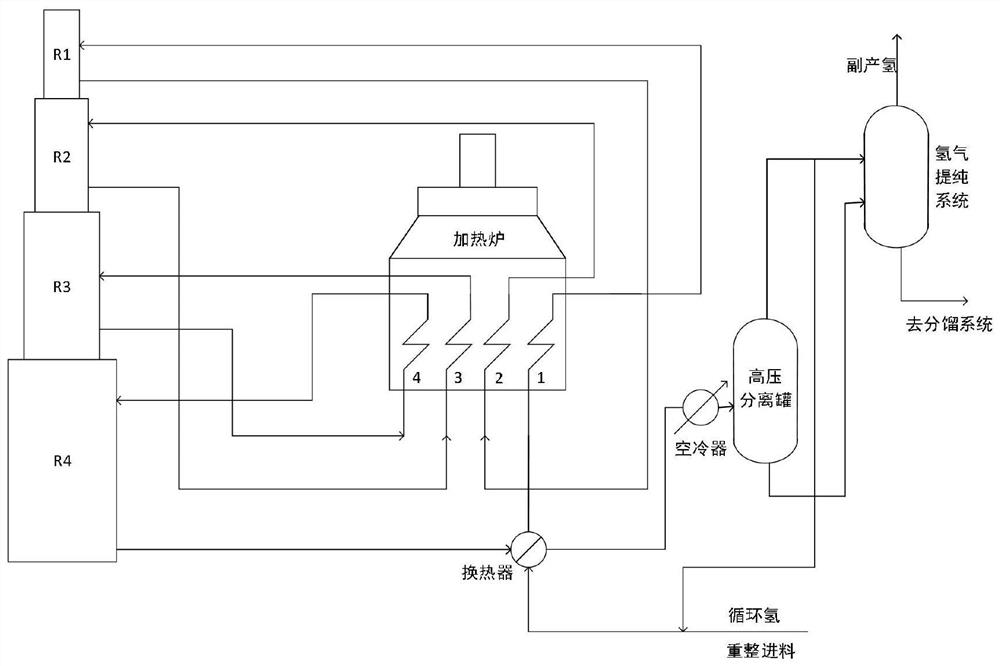

[0108] Such as figure 1 As shown, a process schematic diagram of a continuous catalytic reforming unit, its process production flow is:

[0109] The reforming feed mixes with the circulating hydrogen from the high-pressure vapor-liquid separation tank, exchanges heat with the reforming reaction product through a heat exchanger, and then enters the heating furnace 1. After being heated to a certain temperature in the heating furnace, it enters the first heavy The whole reactor R1 is in contact with the catalyst for reforming reaction; the reaction products and unreacted raw materials from the first reforming reactor R1 enter the heating furnace 2 for heating, and then enter the reactor R2 and heating furnace 3 in sequence , reactor R3, heating furnace 4, and reactor R4. The reaction product from the last reactor R4 exchanges heat with the reform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com