Impact-resistant ultra-thin polyolefin foaming sheet as well as preparation method and application thereof

A polyolefin foaming and foaming sheet technology, which is applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problem of difficulty in ensuring the uniformity of plane thickness, and it is difficult to directly obtain thin foaming sheets and electronic equipment. Stability issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

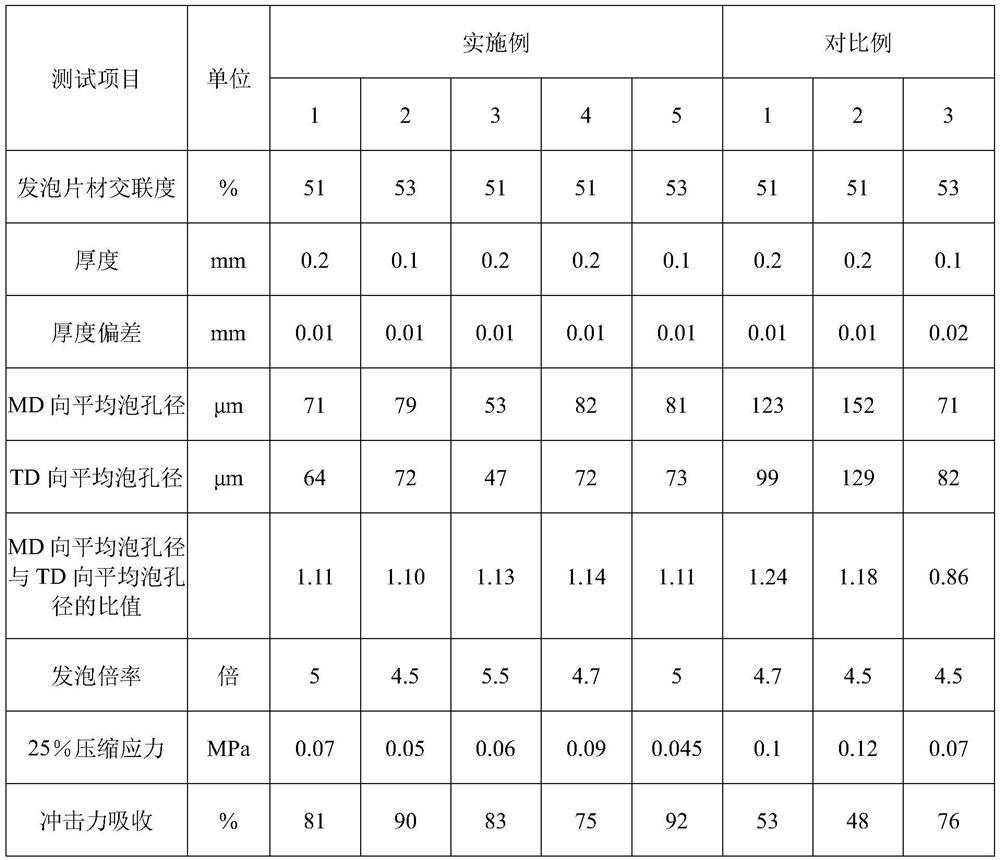

Examples

preparation example Construction

[0034] The impact-resistant ultra-thin polyolefin foam sheet of the present invention, its preparation method comprises the steps:

[0035] (1) Foaming agent modification

[0036] The foaming agent particles are mixed with fumed silica according to a certain ratio, and fully mixed uniformly in a stirring device to prepare modified foaming agent particles; the ratio of fumed silica to foaming agent particles is preferably 1:10 to 1:99 ;

[0037] (2) Granulation

[0038] Mix the modified foaming agent particles and other additives with polyolefin resin in step (1) and banbury respectively. The temperature of the banbury chamber is 80-180°C, the pressure is 1-2MPa, and the banbury time is 5-25min. Put the resin into a single-screw or twin-screw hopper after kneading, and the processing temperature in the screw barrel is 100-180°C. After extrusion, stranding, pelletizing, and drying processes, the foaming agent resin masterbatch is finally obtained. and antioxidants or other re...

Embodiment 1

[0057] (1) Foaming agent modification: Azodicarbonamide and fumed silica are mixed in a stirring device in a weight ratio of 19:1, and the particle size of the foaming agent after modification is 8 μm, and the weight part is 10 servings.

[0058] (2) Granulation: The obtained modified foaming agent, low-density polyethylene (LDPE) resin, and ethylene-vinyl acetate copolymer (EVA) are mixed and banburyed in a weight ratio of 10:55:35. The bin temperature is 150°C, the pressure is 1.5MPa, and the banburying time is 15min. Put the resin that has been kneaded into agglomerates into the twin-screw hopper, and the processing temperature in the screw barrel is 135°C. , drying process, and finally obtain the modified foaming agent resin masterbatch;

[0059] (3) Extrusion: the remaining resin particles (modified foaming agent masterbatch: LDPE: EVA: color masterbatch = 40:30:27: 3) Extrude into sheets using a twin-screw extruder, select the die opening at the extrusion port to adjus...

Embodiment 2

[0065] The difference from Example 1 is that, in order to obtain a thinner foam sheet, ethylene-propylene rubber (EPR) is added as a resin modifier at the same time. Soft rubber has excellent low-temperature impact resistance, good fluidity and controllable molding shrinkage. It has a greater improvement in tensile deformation and can make thinner foam sheets. The same blowing agent modification process and granulation process as in Example 1, the difference is that the extrusion process formula particle ratio is modified blowing agent master batch: LDPE: EVA: EPR: color master particle=38:25: 13:21:3, select the extrusion die opening to be adjusted to 0.35mm, and extrude the sheet by calendering and cooling to obtain a foamed sheet substrate with a thickness of 0.33mm±0.05mm; the obtained foamed sheet substrate is subjected to high-speed Electron beam irradiation, cross-linking by electron irradiation, the irradiation dose is 25Mrad, to obtain a foam sheet mother sheet; the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive stress | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com