Method for preparing 2, 5-dimethylfuran through catalytic hydrogenation of 5-hydroxymethylfurfural

A technology for hydroxymethylfurfural and dimethylfuran, which is applied in the field of preparation of 2,5-dimethylfuran, can solve the problems of complicated catalyst preparation and maintenance process, catalyst deactivation, catalyst deactivation and other problems, and achieves obvious advantages and industrial application value, simple preparation method and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] (1) Preparation of graphene carrier: take 230mL concentrated sulfuric acid and 5.0gNaNO 3 , stir and add 10g of natural flake graphite powder, stir for 2.5h and add 30g of KMnO 4 , transferred to a constant temperature water bath at 35°C for 2 hours, added 460 mL of deionized water, stirred in an oil bath at 98°C for 15 minutes, and finally added 1.4L of deionized water to terminate the reaction, and at the same time added 25 mL of 30% H 2 o 2 , down to room temperature, deionized water centrifugal washing to neutrality, to obtain paste graphene oxide (GO), record its dry basis content as 1wt%; get the GO paste prepared by the above-mentioned method of 100g, disperse in 1000mL deionized water, Ultrasonic treatment for 30 minutes, static aging, adding 25mL of 30% ammonia water and 6mL of 80% hydrazine hydrate, refluxed in an oil bath at 95°C for 3 hours, adding 4mL of 80% hydrazine hydrate for 30 minutes, adding 4% hydrochloric acid solution, suction filtration while ho...

Embodiment 2

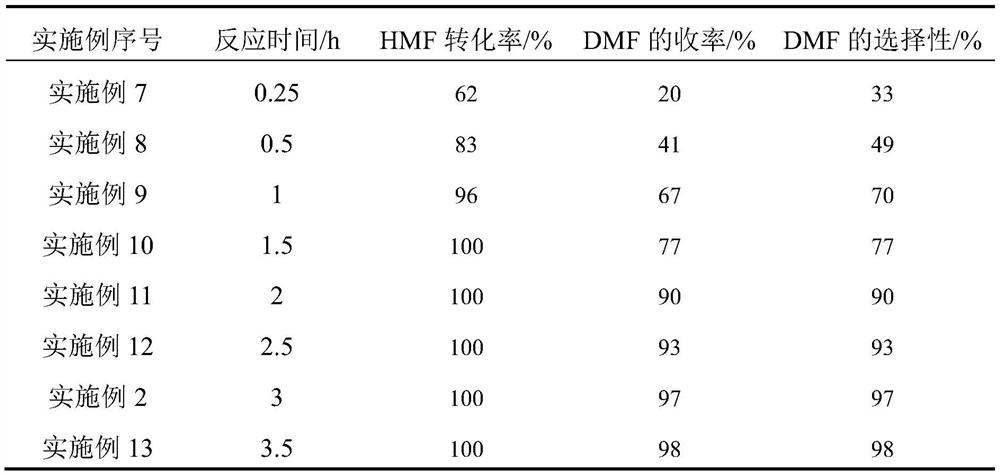

[0041] The intermittent reaction of embodiment 2,4-6 different reaction pressures

[0042] 1. Catalyst preparation: the same as the catalyst preparation process in Examples 1-3.

[0043] 2. Reaction test: the operation process is the same as the reaction test process in the embodiment 1-3, and the specific reaction conditions: after ensuring that the device does not leak, pass into the specified pressure H 2 , a stirring rate of 500 rpm, and a set temperature of 200° C. for 3 h.

[0044] 3. The reaction results are shown in Table 2.

[0045] Table 2 Results of different reaction pressures

[0046]

[0047] From Examples 2, 4-6, it can be seen that the conversion rate of HMF can reach 100% under the conditions of 1 MPa-4 MPa and 200° C. for 3 hours. When H 2 When the pressure is 1.0MPa, it also has good catalytic activity, and the DMF yield can reach 78%; when H 2 When the pressure increased to 2.0MPa, the yield of DMF reached 97%. Explain that 2.0MPa H in the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com