Aluminum titanate porous ceramic, preparation method thereof and porous medium burner

A technology of porous ceramics and aluminum titanate, which is used in burners, ceramic products, gas fuel burners, etc., can solve problems such as poor thermal shock resistance at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

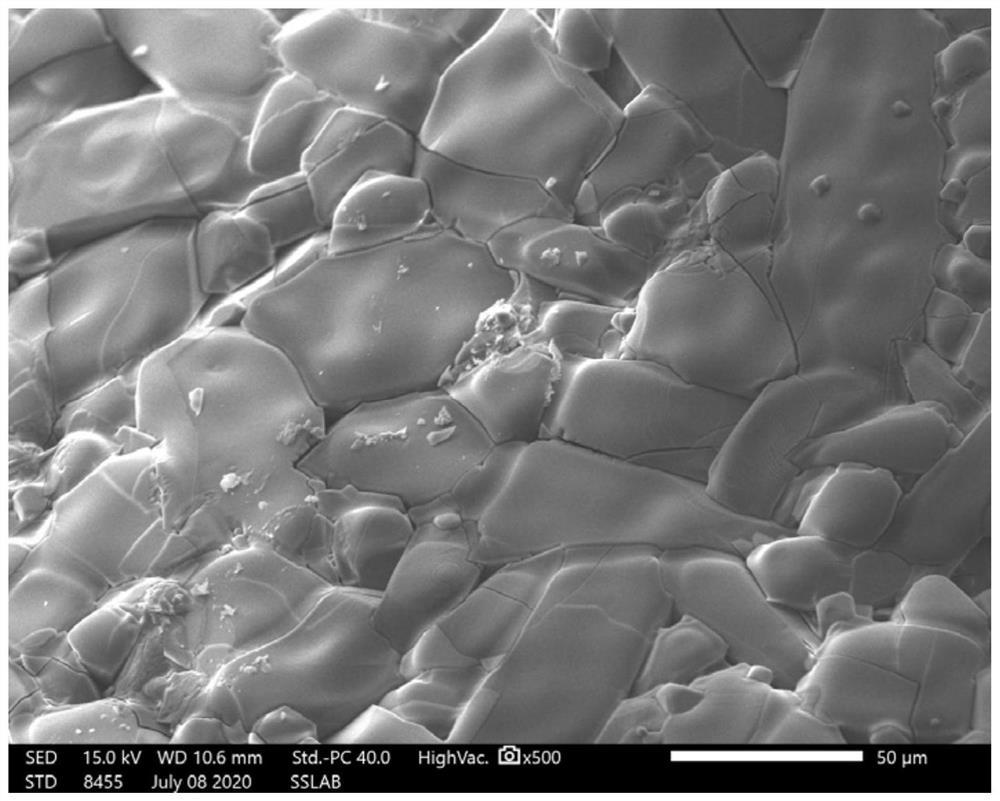

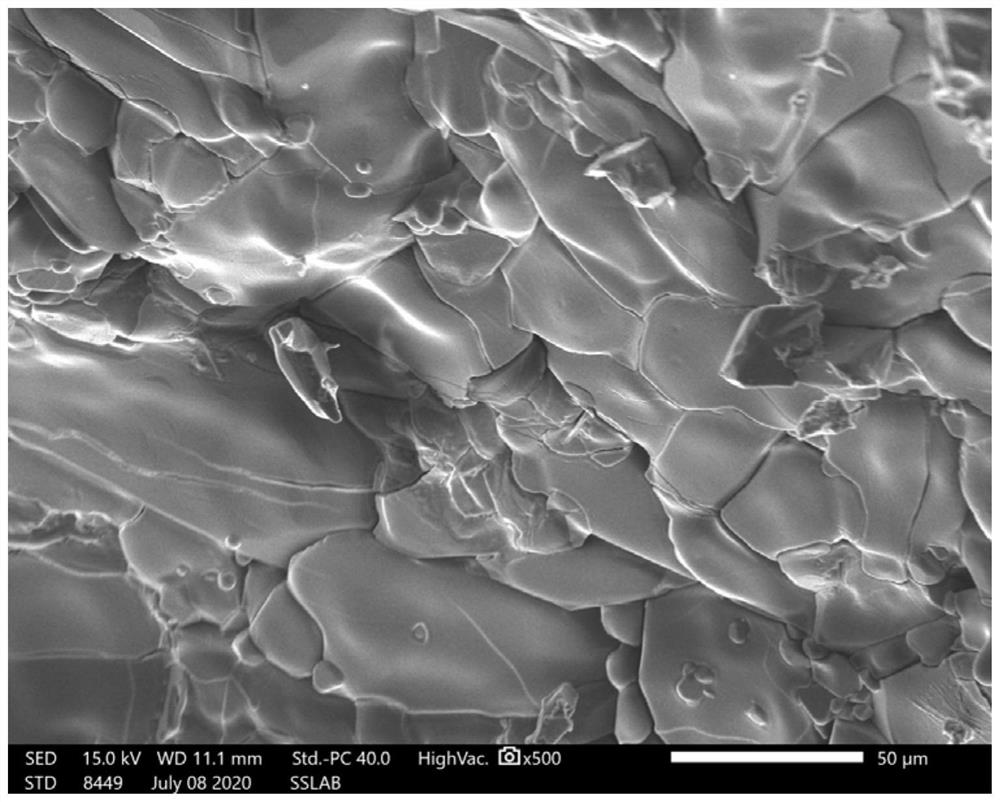

Image

Examples

preparation example Construction

[0033] In the second aspect, the embodiment of the present application provides a method for preparing the aluminum titanate porous ceramic according to the embodiment of the first aspect, comprising: immersing the foamed plastic with pores in the slurry of the raw material, and making the skeleton surface of the foamed plastic coated with slurry , dry and solidify after hanging the slurry, and then sinter to shape after pyrolysis.

[0034]The foamed plastics with pores are dried and solidified after hanging the slurry, so that the slurry is cured on the surface of the foamed plastics skeleton, and the adhesive is cured after pyrolysis to make the Al 2 o 3 、TiO 2 It is consolidated with the stabilizer and the foamed plastic is decomposed at the same time, the pores of the foamed plastic correspond to the pores of the aluminum titanate porous ceramic, so that the porosity of the prepared aluminum titanate foamed ceramic is relatively high. Optionally, the foam plastic in the ...

Embodiment 1

[0051] This embodiment provides an aluminum titanate porous ceramic, the raw material of which includes: calcined α-Al 2 o 3 powder (D50=1μm) 2.5kg, anatase type titanium dioxide (D50=0.3μm) 2.5kg, magnesium oxide powder (D50=0.5μm) 150g, ferric oxide (analytical pure) 11.5g, lanthanum oxide (analytical Pure) 20g, phenolic resin 1kg, Tween 20 of 10g, ethanol 1600g and butanone 400g.

[0052] The preparation method of the aluminum titanate porous ceramic of the present embodiment comprises:

[0053] Put the above raw materials in a ball mill tank for 4 hours to prepare a slurry, cut the polyurethane sponge into 300mmx300mmx25mm, dip the sponge into the slurry, take it out and centrifuge, shake off the excess slurry, and use compressed air to hang the precursor on the The slurry is evenly purged, and the compressed air pressure is 0.3MPa. Place the polyurethane sponge after slurrying in an oven to dry and solidify at 100°C, repeat the process of dipping, centrifuging, purging...

Embodiment 2

[0055] This embodiment provides an aluminum titanate porous ceramic, the raw material of which includes: calcined α-Al 2 o 3 powder (D50=2μm) 3kg, rutile titanium dioxide (D50=0.5μm) 2kg, magnesite powder (D50=2μm) 350g, ferric oxide (analytical pure) 15g, lanthanum oxide (analytical pure) 40g, phenolic Resin 1.2kg, castor oil 20g, ethanol 1500g and butanone 500g.

[0056] The preparation method of the aluminum titanate porous ceramic of the present embodiment comprises:

[0057] Put the above raw materials in a ball mill tank for 5 hours to prepare a slurry, cut the polyurethane sponge into 140mmx290mmx25mm, dip the polyurethane sponge into the slurry, take it out and centrifuge, shake off the excess slurry, and hang the precursor with compressed air The slurry is blown evenly, and the compressed air pressure is 0.6MPa. Put the slurry-coated polyurethane sponge in an oven to dry and solidify at 120°C, repeat the process of dipping, centrifuging, purging, and drying and cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com