Magnetic core material, and preparation method and application thereof

A magnetic core material and magnetic technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of poor repression and high loss of high-impedance iron-silicon-chromium materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

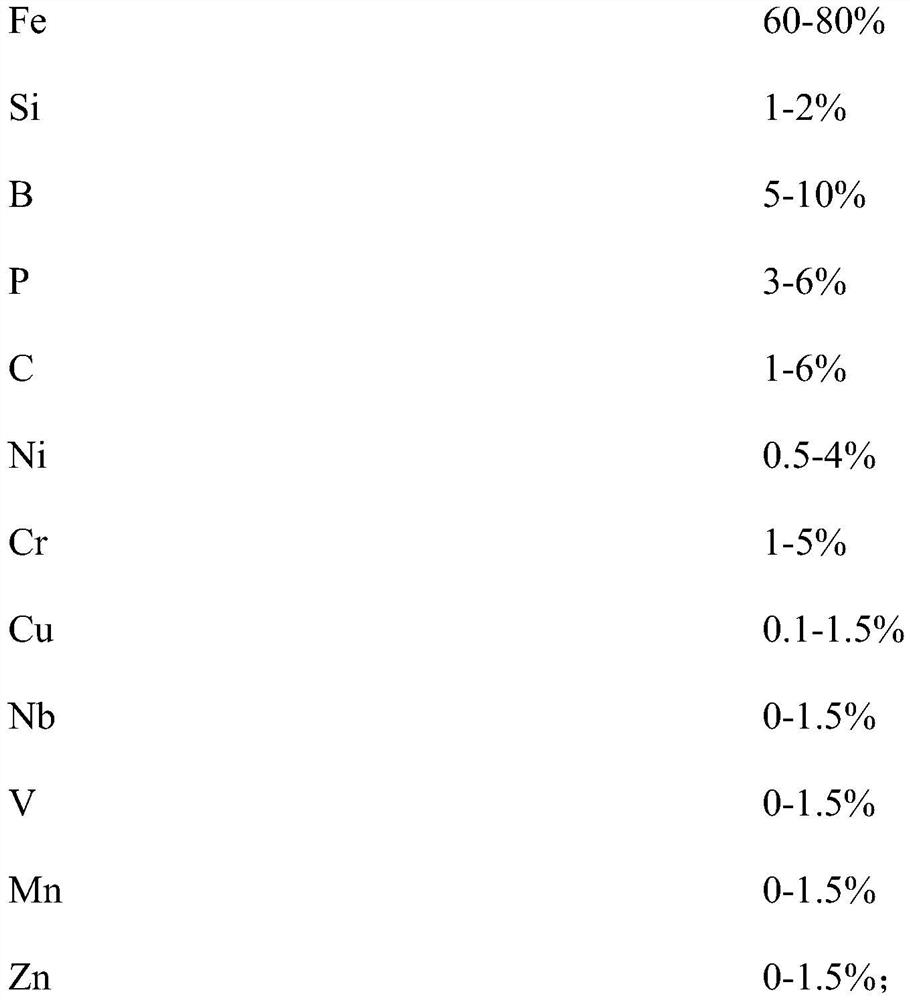

[0098] This embodiment provides a magnetic core material and a preparation method thereof, the preparation method comprising the following steps:

[0099] (1) Mixing the first magnetic powder, the second magnetic powder and the third magnetic powder with a mass ratio of 7:2:1 to obtain a ternary magnetic powder; wherein the first magnetic powder is Fe 77.1 Si 1 B 6 P 5.5 C 4.5 Ni 2 Cr 3 Cu 0.5 Nb 0.1 V 0.1 mn 0.1 Zn 0.1 , the particle size distribution is D10=3.5 μm, D50=13.5 μm, D90=30 μm; the second magnetic powder is aerosolized FeSi powder, the particle size distribution is D10=1.25 μm, D50=4 μm, D90=8 μm; the third magnetic powder is Carbonyl iron powder, the particle size distribution is D10=1.5μm, D50=3.5μm, D90=6μm;

[0100] (2) Mixing ternary magnetic powder, phosphoric acid and acetone, stirring until the acetone is completely volatilized, followed by drying, grinding, sieving and baking to obtain passivated magnetic powder; the phosphoric acid accounts fo...

Embodiment 2

[0105] This embodiment provides a magnetic core material and a preparation method thereof, the preparation method comprising the following steps:

[0106] (1) Mixing the first magnetic powder, the second magnetic powder and the third magnetic powder with a mass ratio of 6:3:1 to obtain a ternary magnetic powder; wherein the first magnetic powder is Fe 60 Si 2 B 10 P 6 C 6 Ni 4 Cr 5 Cu 1.5 Nb 1.5 V 1.5 mn 1.5 Zn 1 , the particle size distribution is D10=3μm, D50=12μm, D90=25μm; the second magnetic powder is aerosolized FeNi powder, the particle size distribution is D10=0.5μm, D50=2μm, D90=6μm; the third magnetic powder is reduced iron powder, the particle size distribution is D10=1μm, D50=3μm, D90=5μm;

[0107] (2) Mixing ternary magnetic powder, phosphoric acid and acetone, stirring until the acetone is completely volatilized, followed by drying, grinding, sieving and baking to obtain passivated magnetic powder; the phosphoric acid accounts for 0.1% of the mass of t...

Embodiment 3

[0112] This embodiment provides a magnetic core material and a preparation method thereof, the preparation method comprising the following steps:

[0113] (1) Mixing the first magnetic powder, the second magnetic powder and the third magnetic powder with a mass ratio of 6.5:2.5:1 to obtain a ternary magnetic powder; wherein the first magnetic powder is Fe 80 Si 1.5 B 5 P 3 C 5 Ni 0.5 Cr 4 Cu 1, the particle size distribution is D10=4μm, D50=15μm, D90=35μm; the second magnetic powder is gas atomized FeSiAl powder, the particle size distribution is D10=2μm, D50=6μm, D90=10μm; the third magnetic powder is water atomized FeSiCr powder, the particle size distribution is D10=2μm, D50=4μm, D90=7μm;

[0114] (2) Mix the ternary magnetic powder, phosphoric acid and acetone, and stir until the acetone is completely volatilized, followed by drying, grinding, sieving and baking to obtain the passivated magnetic powder; the phosphoric acid accounts for 0.3% of the mass of the ternar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com