Aluminum oxide protection silver nanowire transparent electrode, production method and application thereof

A technology of silver nanowires and transparent electrodes, applied in cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, circuits, etc., can solve problems such as high price, uneven surface morphology, and complex processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

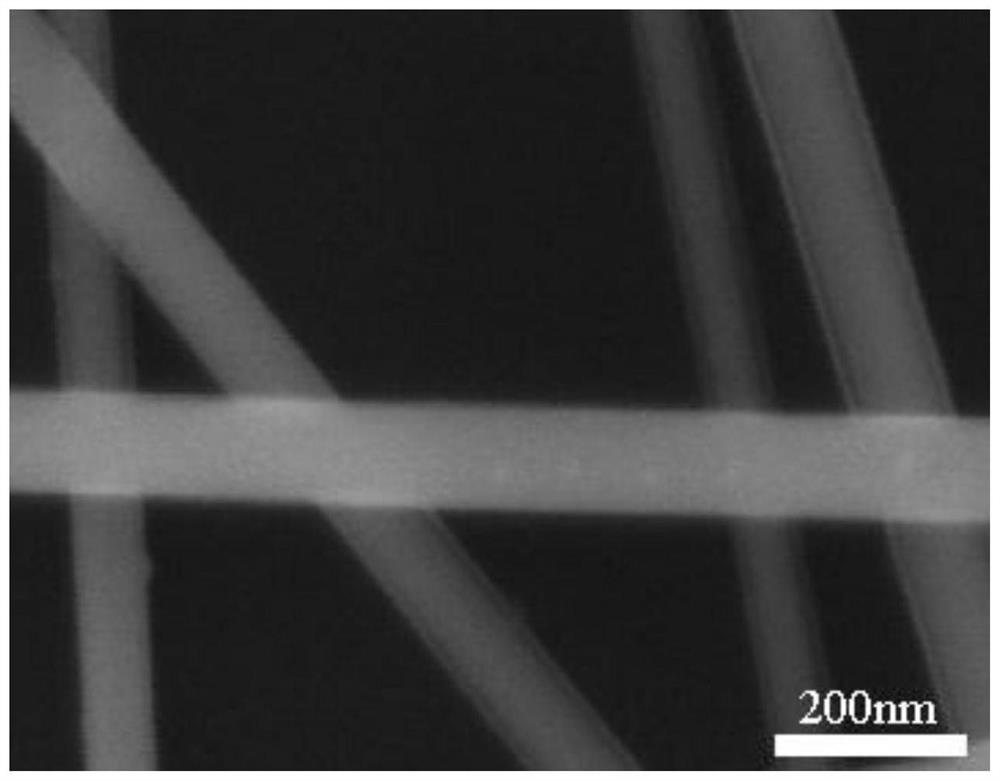

[0047]A glass sheet having a specification of 10 mm × 10 mm is placed on the hierarchy, and the concentration of silver nanowire ethanol is applied to the glass sheet, and the specific spin coating step is: regulating the elongate machine low speed 450 rpm rotation, During the low speed rotation, the suspension of 20 μl of silver nanowire ethanol is added to the glass sheet, and the low speed rotation is 10s, then turn to 3000 rpm high-speed rotation, rotate 30s; repeat the above-mentioned silver nanowire ethanol suspension under 450 rpm. Low-speed rotation - a high-speed rotating spin coating step 1, and the spin coated glass sheet is placed at 110 ° C for 30 min at a constant temperature platform, i.e., the preparation of a transparent electrode based on silver nanowires.

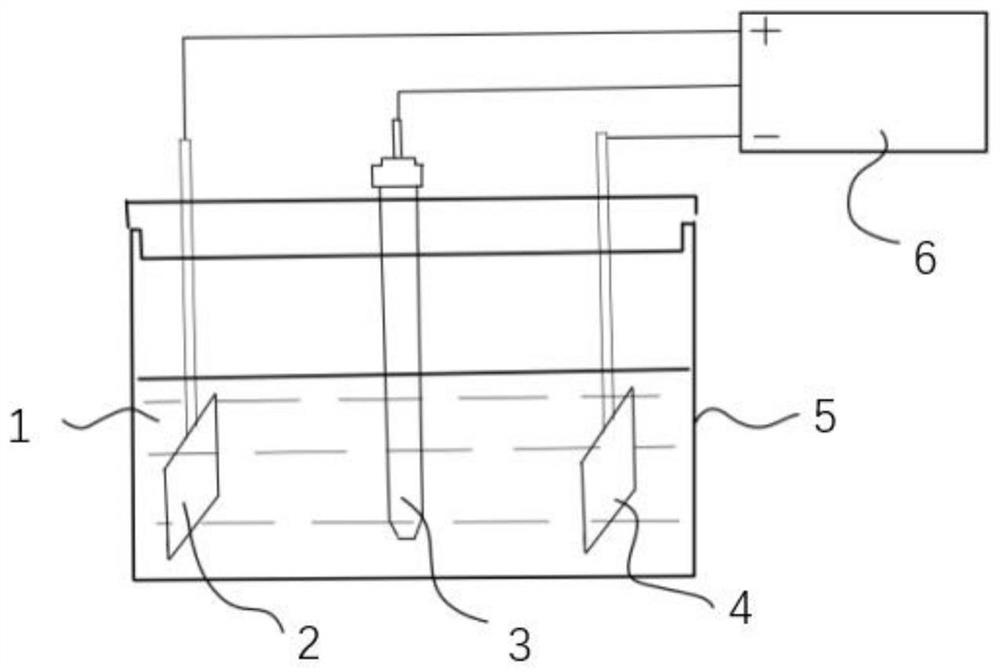

[0048]The aqueous solution of 200 ml containing 2 mmol / L nine hydrogen nitrate and 0.15 mol / L of potassium nitrate was configured as an electrolyte, heated to 75 ° C, and the silver nanowire transparent electr...

Embodiment 2

[0054]The silver nanowire ethanol suspension of 0.5 ml of concentration of 1.2 mg / ml was diluted to 50 mL, which was filtered with a nylon filter having a hole diameter 10 μm. Subsequently placed on the glass back sheet flexible Pi (10 mm × 10 mm) ), Turn on the pump to maintain 1 min. The substrate to which the filtration transfer is completed is placed at 110 ° C for 30 min on the thermostatic platform, i.e., the preparation of a transparent electrode based on silver nanowires.

[0055]The aqueous solution of 200 ml 2 mmol / L nine hydrogen nitrate and 0.15 mol / L of potassium nitrate is configured as an electrolyte, heated to 75 ° C, and the silver nanowire transparent electrode is clamped as a cathode, and the platinum electrode is used as an anode, silver | chlorine | chlorine | The silver electrode is immersed in the electrolyte, and the -1.5V operating voltage is applied by a constant voltage source, and the electrodeposition is 60 min. When the power is disconnected, the ele...

Embodiment 3

[0057]The transparent electrode based on silver nanowire was prepared using the same method as in the same manner, and a water solution containing 1 mmol / L nine hydrogen nitrate and 0.15 mol / L of potassium nitrate was configured as an electrolyte, heated to 75 ° C, and transparently transmitted the silver nanowire The platinum electrode is clamped as the cathode, the platinum electrode as an anode, silver | chlorinated electrode is immersed in the electrolyte, and the working voltage is applied to the electrolyte, and the electrodeposition is 35min, the power supply will be disconnected. The silver nanowire transparent electrode after electrodeposition is immersed in the stirring state, and the maintenance of the stirring is maintained for 20s, then annealing 150 ° C on the hot stage for 15 min, that is, the completionFigure 6 The preparation of the highlands of alumina protective highlands of silver nano-wire transparent electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com