Composition, elastomer, preparation method and application of halogen-free flame retardant ethylene octene copolymer/polylactic acid thermoplastic elastomer

A technology of ethylene octene copolymer and thermoplastic elastomer, which is applied in the field of ethylene octene copolymer/polylactic acid blend thermoplastic elastomer material, and can solve problems such as a large number of toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

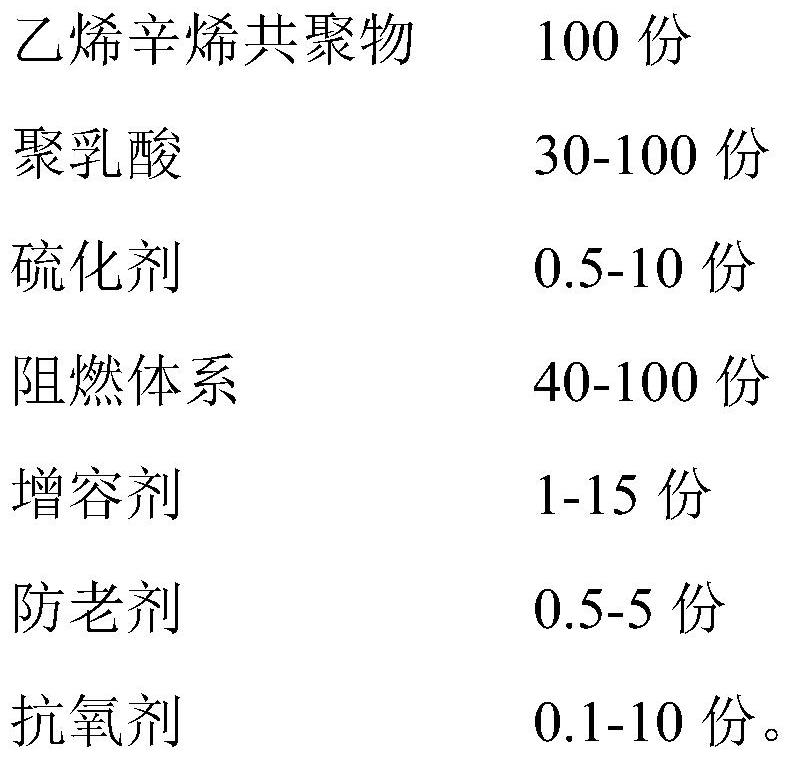

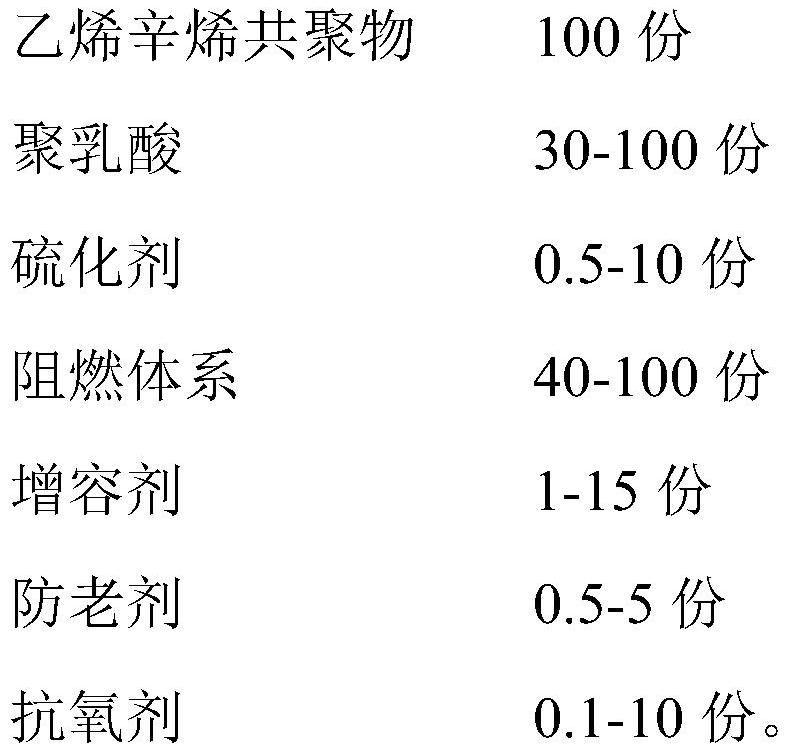

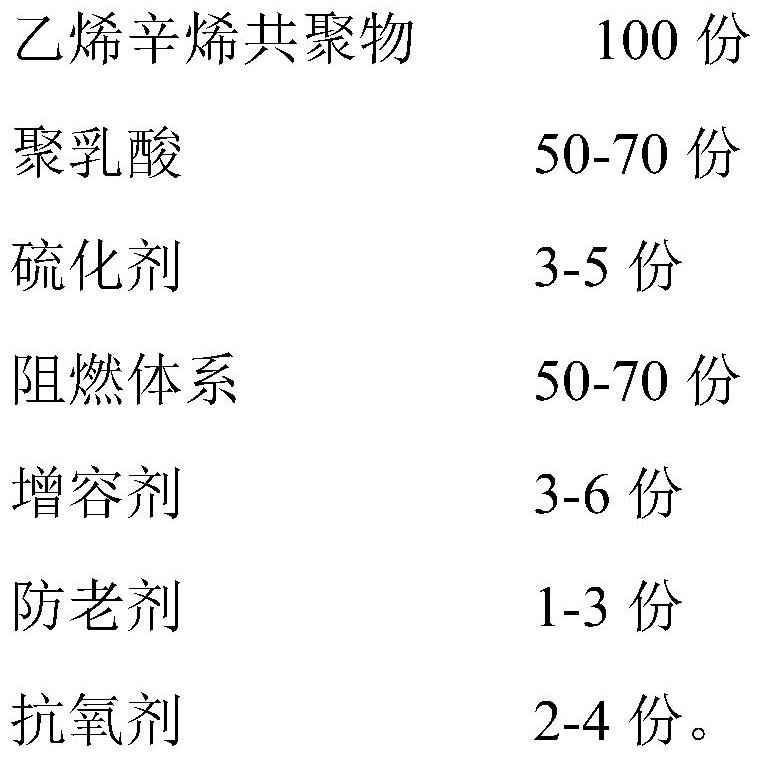

Method used

Image

Examples

Embodiment 1-8

[0044] Using the formula composition shown in Table 1, the following processing methods were used to obtain elastomers P1-P8.

[0045] (1) At a temperature of 200 °C, polylactic acid, an antioxidant (2,2,4-trimethyl-1,2-dihydrovaline), an antioxidant (tetra[β-(3,5) -Di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester) was added into the mixer, after the polylactic acid was melted, the ethylene octene copolymer and the compatibilizer (diphenylmethane diisocyanate) were added, and the melted co-polymer After mixing, a kneaded material is obtained, and the kneaded material is extruded and granulated through a single-screw extruder to obtain kneaded material granules.

[0046] (2) A co-rotating intermeshing twin-screw extruder is used, the screw speed is 100 rpm, the main feeding speed is 40 rpm, the head temperature is 180 ℃, the temperature of the screw feeding section is 150 ℃, and the temperature of the melt-kneading section is 180 ℃, In the above-mentioned co-...

Embodiment 9

[0048] The formula composition shown in Table 1 was used, except that the following processing conditions were used for dynamic vulcanization processing: a co-rotating twin-screw extruder was used, the screw speed was 150 rpm, the main feeding speed was 40 rpm, and the head temperature was 190 ℃ , the temperature of the screw feeding section is 170 ℃, and the temperature of the melting and kneading section is 190 ℃, adding the mixing material particles and vulcanizing agent, dynamically vulcanizing and extruding, and granulating to obtain TPV particles P9.

Embodiment 10

[0050] The TPV particles were prepared by the method described in Example 1, except that the flame retardant system used was 45 parts by weight of polypentaerythritol to obtain TPV particles P10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com