Transparent flame-retardant UV coating and preparation method thereof

A flame-retardant and transparent technology, which is applied in the field of transparent flame-retardant UV coatings and its preparation, can solve the problems of incompatibility between flame retardancy and transparency, and the inability of components to form a homogeneous system, so as to maintain the original appearance of cultural relics and solve the problem of The effect of flame retardant problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

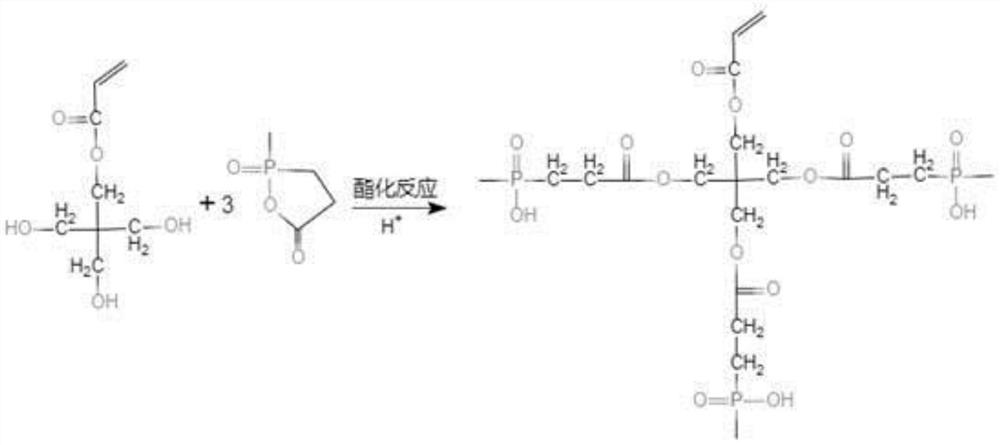

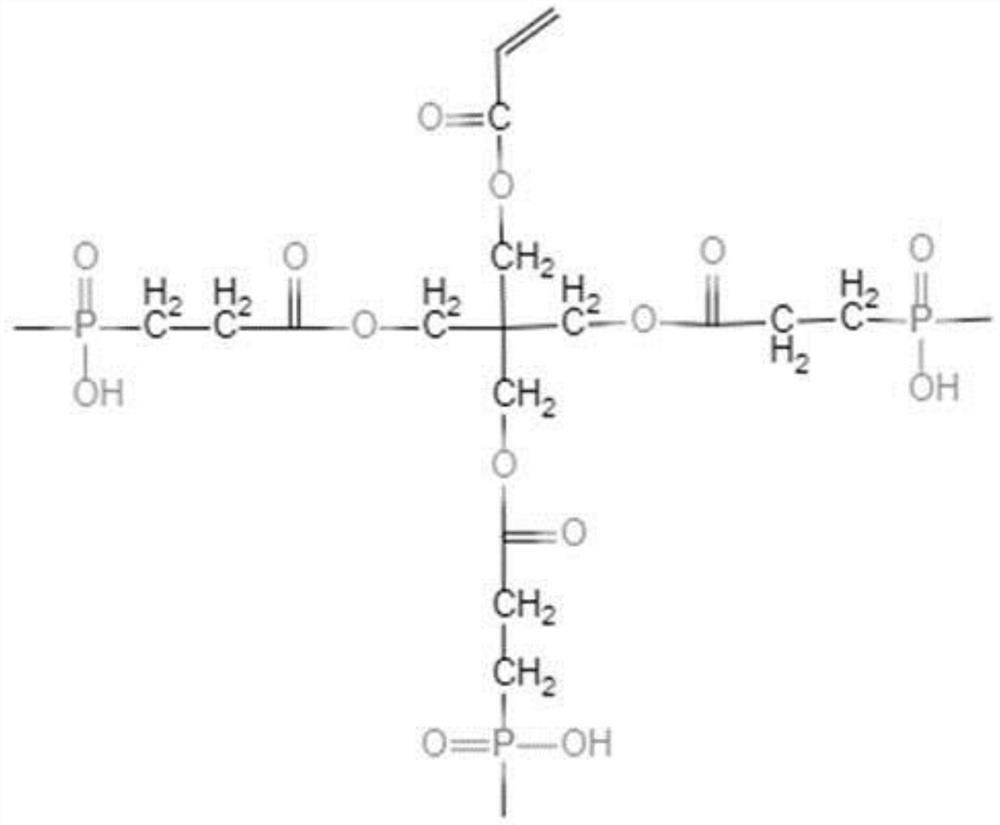

[0063] The preparation steps of phosphorus-containing pentaerythritol acrylate monomer:

[0064] According to the molar ratio of cyclic phosphoric anhydride and pentaerythritol acrylate is 1:1.2, weigh cyclic phosphoric anhydride and pentaerythritol acrylate, and then weigh a certain amount of strong acid cation exchange resin catalyst and hydroquinone polymerization inhibitor, wherein the catalyst It accounts for 1% of the total mass fraction of cyclic phosphoric anhydride and pentaerythritol acrylate, and the polymerization inhibitor accounts for 0.2% of the total mass fraction of cyclic phosphoric anhydride and pentaerythritol acrylate.

[0065] Put the weighed cyclic phosphoric anhydride into a three-necked round-bottomed flask equipped with a condenser tube, add a strong acid cation exchange resin and hydroquinone, stir and heat it to 90 ° C through an oil bath, and then slowly use a constant pressure dropping funnel. Pentaerythritol acrylate was added dropwise, and the t...

Embodiment

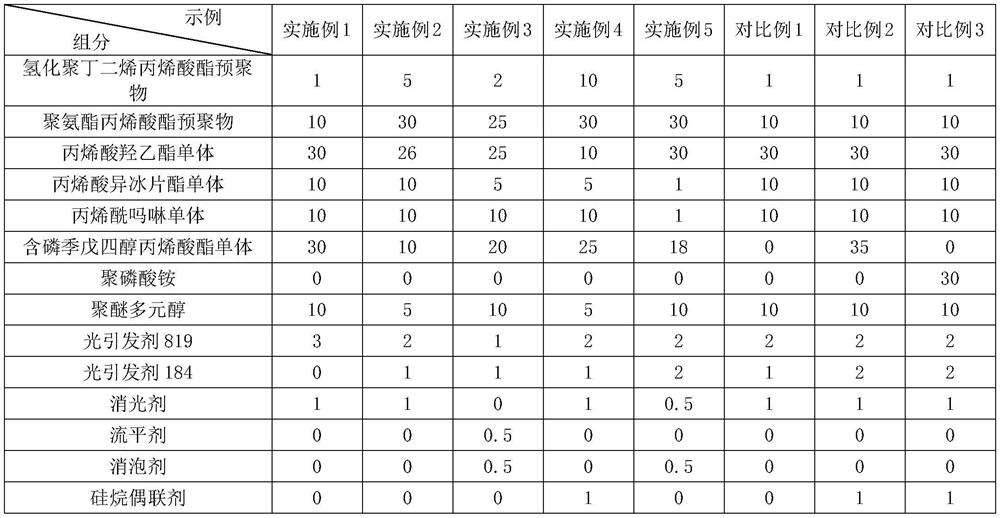

[0068] Preparation steps of transparent flame retardant UV coating:

[0069] Hydrogenated polybutadiene acrylate prepolymer, urethane acrylate prepolymer, hydroxyethyl acrylate monomer, isobornyl acrylate monomer, acryloyl morpholine monomer, phosphorus-containing pentaerythritol acrylate monomer in parts by weight , polyether polyol, photoinitiator and auxiliary agent are mixed together, and the transparent flame retardant UV coating is prepared after stirring for 30 minutes.

[0070] Table 1: The addition amount of each component of Examples 1-5 and Comparative Examples 1-2

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com