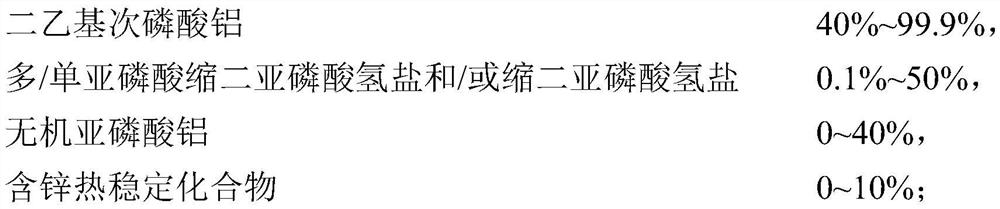

A high heat and high shear resistant, highly flame-retardant, halogen-free flame-retardant compound system and its application

A high flame-retardant, high-shear technology, applied in the field of flame-retardant materials, can solve the problems of low acidity, low shear resistance, low moisture absorption, etc., and achieve the effect of solving flame-retardant problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

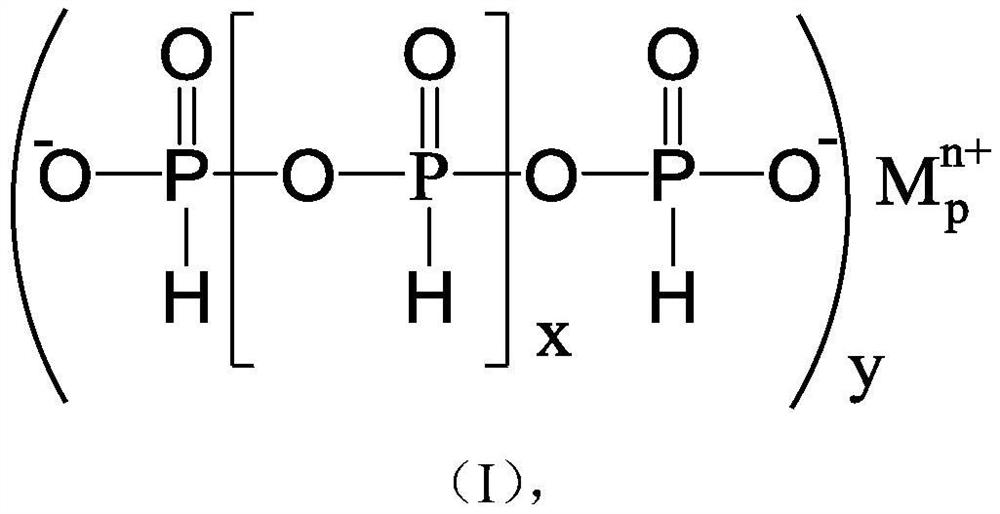

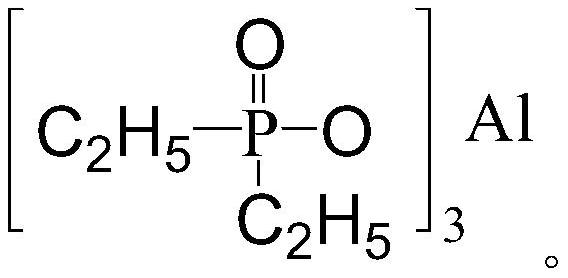

[0046] Preparation of monophosphite dihydrogenaluminum phosphite

[0047] The molecular structure of monophosphite dialuminum hydrogen phosphate is shown in the following formula:

[0048]

[0049] The preparation process is: weigh 82g (1mol) of phosphorous acid, 540g (2mol) of aluminum hydrogenphosphite ((H 2 PO 3 ) 3 Al) and the concentrated phosphoric acid (H of 12g concentration 85.1wt%) 3 PO 4 ), dissolved in 1500g of water, fully stirred and mixed evenly, reacted at 85°C for 3 hours, and rotated at -0.08MPa at 85°C to evaporate the water to 50wt%. Transfer the material to an oven, heat up to 130°C, and dry for 120 minutes. The moisture content of the solid is 0.2wt%. The materials were washed and separated until the washing was completed when the conductivity of the washing water was less than 50 μs / cm, dried at 130°C, and the moisture content was 0.08wt%, the materials were pulverized, the average particle size D50 was 40 μm, and the yield was 97.8%, and carried...

Embodiment 1

[0053] The compound flame retardant system is applied to glass fiber reinforced nylon, and the performance of the flame retardant is investigated according to the following steps and test methods.

[0054] 1) Mixing of halogen-free flame retardant system

[0055] Add the components of the compound flame retardant system to the high-speed mixer according to the ratio in Table 1, start high-speed stirring, and stir for 10 minutes to complete the mixing of the halogen-free flame retardant system, discharge, and test for use.

[0056] 2) Extrusion granulation of materials

[0057] Set the temperature of each zone of the twin-screw extruder at the predetermined temperature. After the temperature is stable for 20 minutes, add the nylon system from the hopper, add the glass fiber through the glass fiber inlet, feed the flame retardant system powder through the powder feeding hole, and start the host And feeder to complete the extrusion granulation of the material. The granulated ma...

Embodiment 2

[0074] The implementation process is the same as in Example 1, except that the flame retardant system is three components, and the total amount of the flame retardant system remains unchanged. Other materials and proportioning are shown in Table 1, and the obtained material results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com