Method for preparing hydrogen, oxygen and hydrocarbon mixed gas through reaction of rare earth diboron dicarbon material and water

A technology for the reaction of mixed gas and water, which is used in the production of hydrogen and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

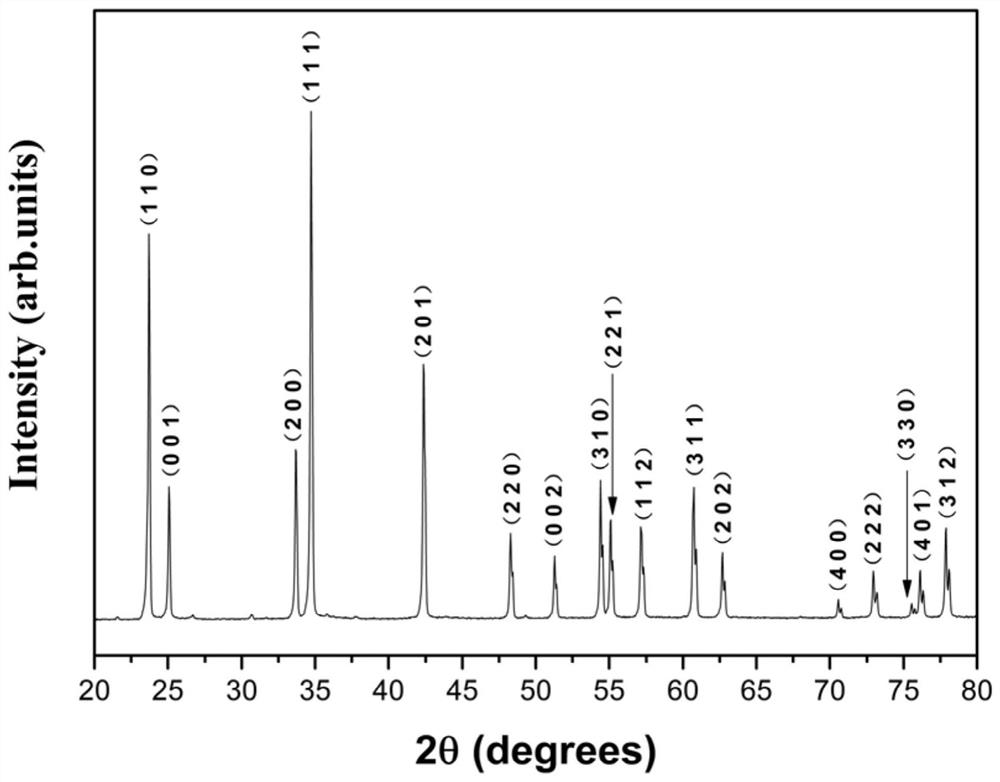

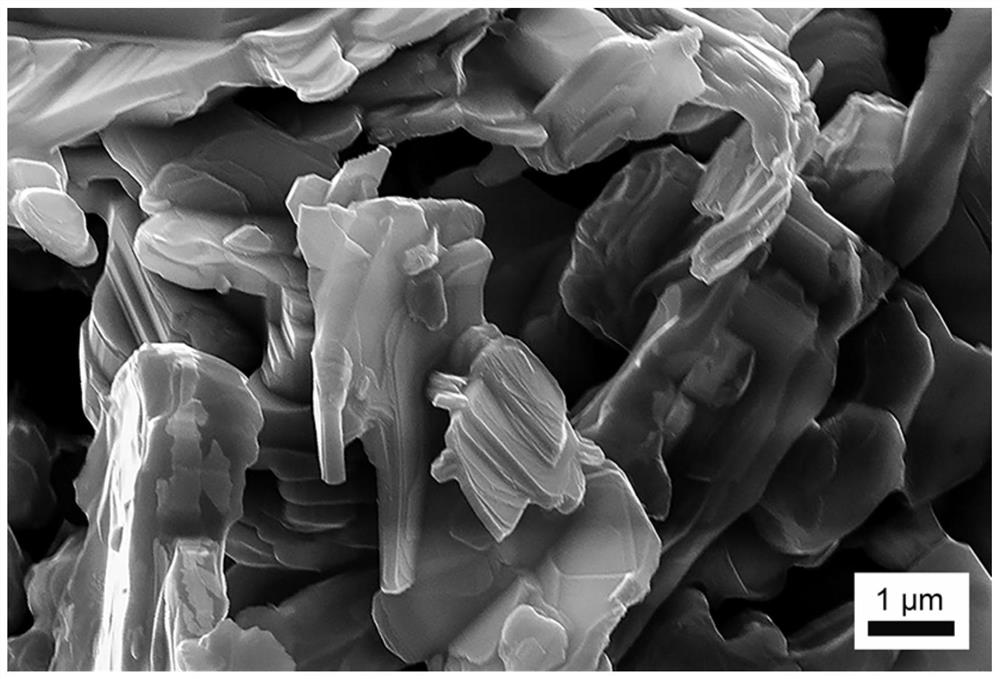

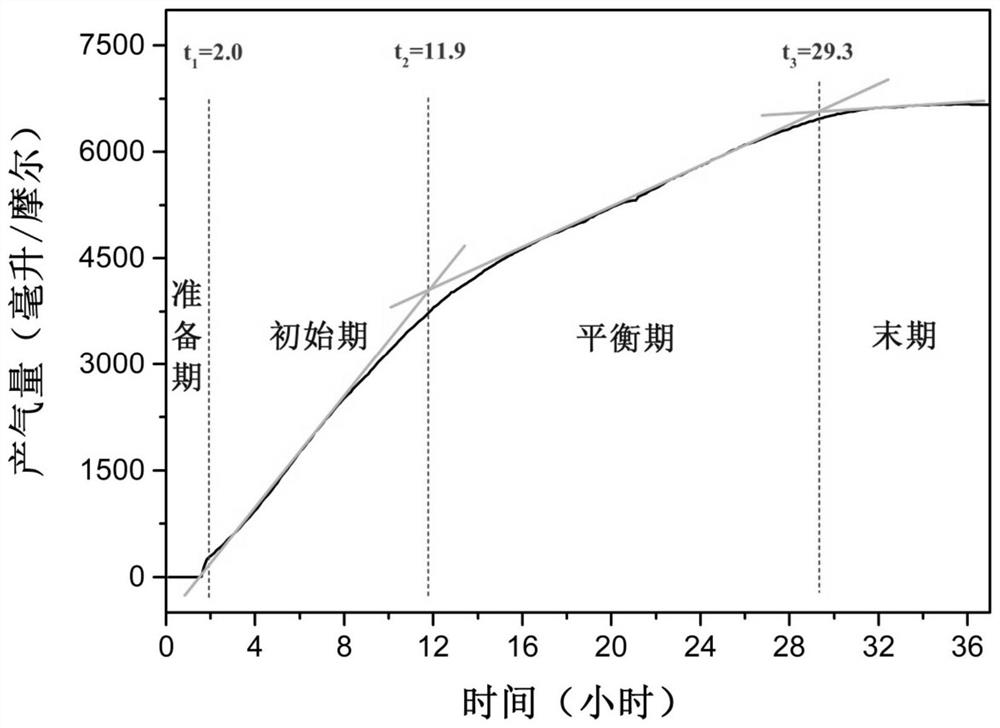

[0033] In this example, the 300 mesh Yb 2 o 3 Powder 49.24g, 200 mesh B 4 7.88g of C powder and 12.88g of 200 mesh C powder were put into a silicon nitride ball mill tank and ball-milled with absolute ethanol for 6h, dried at 60°C for 24h, passed through a 100-mesh sieve, then put into a graphite crucible, and the graphite crucible was sintered in the furnace Carry out sintering with a heating rate of 20°C / min, and keep warm for 8h when rising to 1800°C. The whole sintering process is carried out under the protection of high-purity argon (the volume purity of argon is above 99.999%). Such as figure 1 As shown, the obtained reaction product is subjected to XRD analysis, and it can be found that the prepared material is YbB 2 C 2 Mutually. Such as figure 2 As shown, it can be found from the scanning electron microscope photos that the prepared powder has a typical lamellar structure. Pass the sintered sample through a 500 mesh sieve, take 15.00g sample and 500mL H 2 O m...

Embodiment 2

[0039] In this example, the 200 mesh Y 2 o 3 Powder 28.80g, 200 mesh B 4 8.05g of C powder and 13.15g of 200 mesh C powder were put into a silicon nitride ball mill tank and ball milled with absolute ethanol for 12h, dried at 60°C for 24h, passed through a 100 mesh sieve, then put into a graphite crucible, and the graphite crucible was sintered in the furnace Carry out sintering at a heating rate of 5°C / min, and keep warm for 1h when rising to 2200°C. The whole sintering process is carried out under the protection of high-purity argon (the volume purity of argon is above 99.999%). Such as Figure 4 As shown, the obtained reaction product is subjected to XRD analysis, and it can be found that the prepared material is YB 2 C 2 Mutually. Such as Figure 5 As shown, it can be found from the scanning electron microscope photos that the prepared powder has a typical lamellar structure. The sintered sample was passed through a 500-mesh sieve, and 9.25g sample was mixed with 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com