Plugging agent for oil-based drilling fluid and application thereof

A technology of oil-based drilling fluid and plugging agent, applied in the directions of reagents, drilling compositions, products, etc., can solve the problems of poor gel strength, lack of viscoelasticity, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

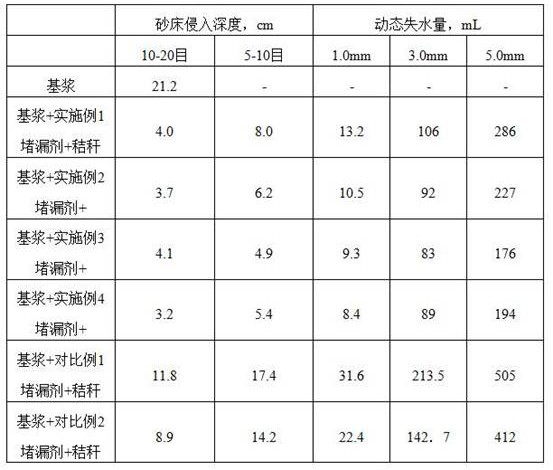

Examples

Embodiment 1

[0044] Heat 52g of tall oil fatty acid in the reactor to 80°C, add 21.3g of ethylenediamine, and introduce N 2 Protected, reacted at 125°C for 4.0h, then added 17.8g of polyethylene glycol 400, stirred for 20min, and dehydrated to obtain a compatibilization modifier; heated 200g of deasphalt with a softening point of 82.6°C to a molten state, and added 29.5g The above compatibilizer was stirred at 155°C for 20 minutes, then 11.5g of LP-3 liquid polysulfide rubber was added and stirred for 30 minutes to obtain modified asphalt.

[0045] Cool the obtained modified asphalt to 120°C, add 17.5g of coco-based 1,3-propylenediamine, stir for 10 minutes, then add 27.2g of CYD-128 type epoxy resin, stir evenly, and keep the temperature at 125°C at 6.0 After the product was cooled to room temperature, it was placed in a freezer at -35°C for 6 hours, and crushed with a pulverizer. Then sieve with 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves to obtain highly elastic modified as...

Embodiment 2

[0048] Heat 40g of tall oil fatty acid in the reactor to 95°C, add 13.8g of ethylenediamine, and introduce N 2 Protected, reacted at 120°C for 3 hours, then added 10.6g of ethylene glycol, stirred for 15min, and dehydrated to obtain a compatibilization modifier; heated 200g of oxidized asphalt with a softening point of 87.8°C to a molten state, and added 17.8g of the above-mentioned compatibilizer agent, stirred at 165°C for 15 minutes, then added 18.2g of liquid nitrile rubber, and stirred for 25 minutes to obtain modified asphalt.

[0049] Cool the obtained modified asphalt to 125°C, add 25.4g of hydrogenated tallow propylene diamine, stir for 15 minutes, then add 35.2g of E-44 type epoxy resin, stir evenly, and react at a constant temperature of 135°C for 5 hours; After the obtained product was cooled to room temperature, it was placed in a freezer at -45°C for 5 hours, and crushed with a pulverizer. Then sieve with 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves t...

Embodiment 3

[0052] Heat 48g of tall oil fatty acid in the reactor to 100°C, add 23.4g of ethylenediamine, and introduce N 2 Protected, reacted at 130°C for 3.0h, then added 17.8g of polyethylene glycol 400, stirred for 25min, and dehydrated to obtain a compatibilization modifier; heated 200g of oxidized asphalt with a softening point of 93.5°C to a molten state, and added 30.4g The above compatibilizer was stirred at 175°C for 15 minutes, then 15.4 g of liquid nitrile rubber was added and stirred for 25 minutes to obtain modified asphalt.

[0053] Cool the obtained modified asphalt to 135°C, add 21.6g of octadecyl dimethyl tertiary amine, stir for 10 minutes, then add 31.8g of CYD-128 type epoxy resin, stir evenly, and keep the temperature at 130°C for 8.0 hours. Reaction: After the obtained product was cooled to room temperature, it was placed in a freezer at -25°C for 7 hours, and crushed with a pulverizer. Then sieve with 40-mesh, 80-mesh, 120-mesh and 160-mesh standard sieves to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com