A kind of method for preparing rubber accelerator ns and rubber accelerator ns

A technology of rubber accelerator and accelerator, which is applied in the field of rubber accelerator preparation, can solve the problems of unsuitable conversion of intermediate products, consumption of large oxidant, and influence on product quality, so as to improve reaction efficiency and product yield, and increase reaction yield , the effect of low comprehensive production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

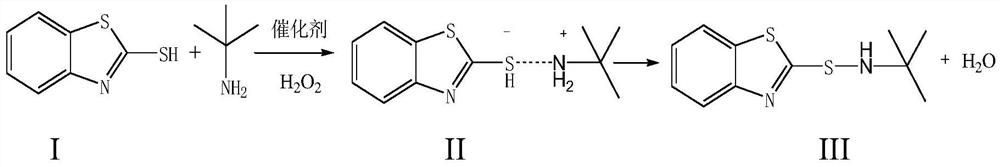

Method used

Image

Examples

Embodiment 1

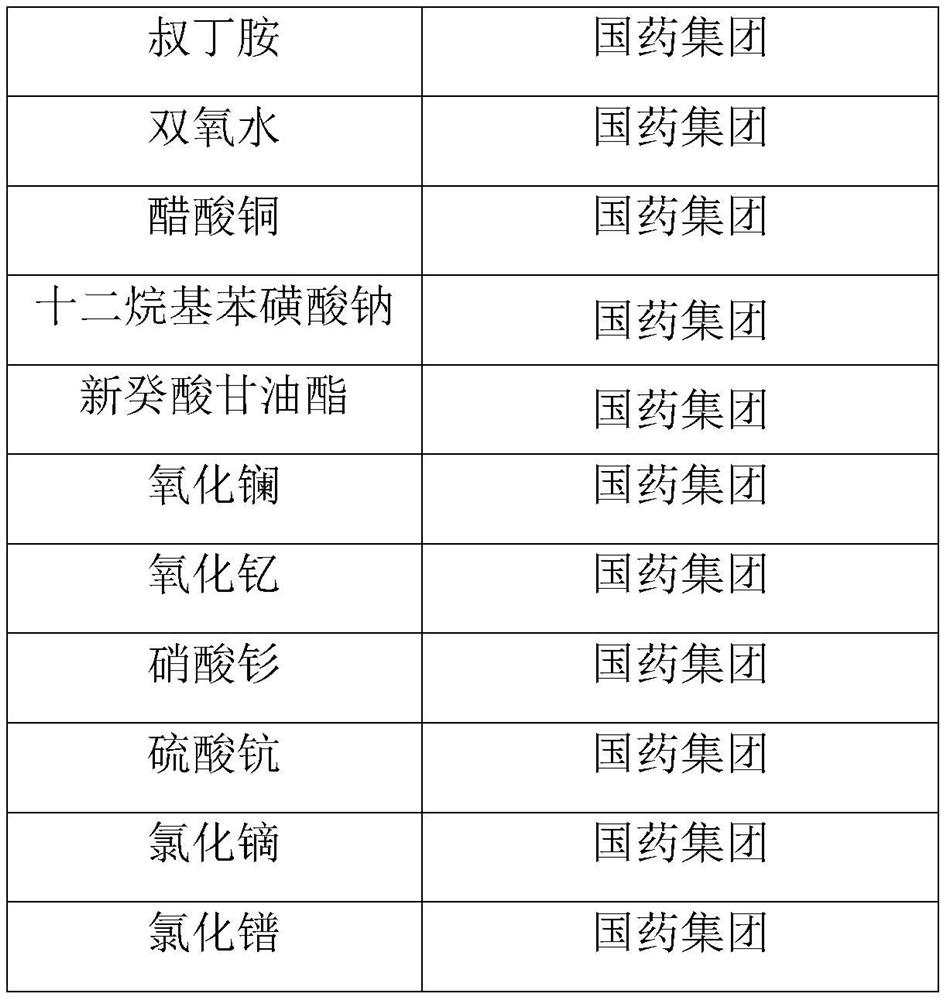

[0042] Add accelerator M 34.4g (0.2mol), neodecanoic acid glyceride 0.35g, tert-butylamine 167g (2.3mol), lanthanum oxide 0.2g into the 500ml reaction flask equipped with stirring device, thermometer and reflux condenser, stir well; The peristaltic pump uniformly added 32.9 g (0.29 mol) of hydrogen peroxide with a concentration of 30% to the reaction vessel, and the reaction temperature was controlled to 35 ° C; the hydrogen peroxide was added dropwise for 90 min, and the reaction was continued for 30 min after the dropwise addition. To obtain the tert-butylamine recovery solution, add 170 g of distilled water to the remaining material, cool down to 25 °C, settle, filter, and recycle the filtrate as a sedimentation solution in the experiment again. The yield is 92.9%, the initial melting point measured by the melting point tester is 107.9°C, and the product is detected by liquid chromatography HPLC, and the purity is 99.2%.

Embodiment 2-6

[0044] Under the premise of not changing the consumption of accelerator M, the addition amount and type of raw materials (tert-butylamine, catalyst, hydrogen peroxide), and reaction conditions such as time and temperature were changed, and the preparation process of accelerator in Example 1 was repeated. The specific data are shown in Table 2 below.

[0045] Table 2

[0046] Example Example 2 Example 3 Example 4 Example 5 Example 6 tert-Butylamine(mol) 1.05 2.6 1.5 1.8 2.0 Hydrogen peroxide (mol) 0.4 0.22 0.25 0.30 0.33 Type of catalyst Yttrium oxide + praseodymium chloride Dysprosium chloride scandium sulfate praseodymium chloride Samarium nitrate Amount of catalyst (g) 0.05+0.10 0.05 0.8 0.3 0.5 Reaction temperature (℃) 40 50 38 30 43 Dropping time (min) 135 120 60 90 100 NS yield (g) 46.0 44.7 46.8 45.1 43.6 NS yield (%) 94.4 91.7 96.0 92.5 89.5 Initial melting point ...

Embodiment 7

[0047] Example 7 Pilot scale-up experiment

[0048] Accelerator M 3440g (20mol), sodium dodecylbenzene sulfonate 30g, tert-butylamine 10200g (140mol), samarium nitrate 60g are added in the pilot-scale reaction kettle of 50L equipped with stirring device, thermometer and reflux condenser, stir well The peristaltic pump uniformly adds 50% concentration of hydrogen peroxide 1632g (24mol) in the reaction vessel, and controls the reaction temperature to 33 ℃; Hydrogen peroxide is added dropwise for 120min, and the dropwise addition is continued for 30min after the completion of the reaction. In the tert-butylamine recovery solution, 15000g of distilled water was added to the remaining material, cooled to 20°C, sedimentation, filtration, and the product was dried at 45°C for 12 hours to obtain 4650g of white granular product NS product, the yield was 95.4%, and the initial melting point measured by the melting point tester was 108.2 ℃, the product was detected by liquid chromatograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com