Method for preparing tert-butylamine

A tert-butylamine and reactor technology, applied in the field of preparing tert-butylamine, can solve the problems of low MTBE conversion rate, strong catalyst corrosion, harsh reaction conditions, etc., and achieve the effects of high conversion rate, improved reaction conversion rate, and sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

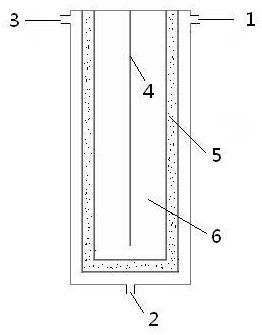

Image

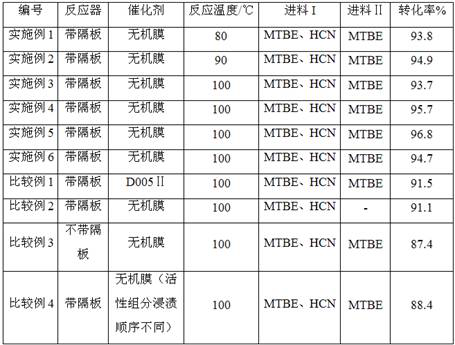

Examples

Embodiment 1

[0034] Preparation of inorganic membrane catalyst: (1) Dissolving 250 grams of zirconium n-butoxide in 250 mL of ethanol to prepare ethanol solution of zirconium n-butoxide; (2) Adding the solution obtained in step (1) dropwise with an aqueous nitric acid solution with a molar concentration of 6 mol / L zirconium n-butoxide ethanol solution to obtain a transparent sol, then add 5g of polyvinyl alcohol and 4g of polyethylene glycol respectively, continue to stir, and further obtain a sol with a certain viscosity, the stirring temperature is 40°C, and the stirring speed is 200r / min; (3) Add α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step b for 2 minutes, pull it out at a pulling speed of 15cm / min, and then heat-treat it at 100°C for 10 minutes, repeat the above steps of immersion, pulling and heat treatment 3 times , and then roasted at 1000°C for 4 hours; (4) impregnate the ceramic tube obtained in step (3) with a concentration of 4mol / L silver nitra...

Embodiment 2

[0037] Preparation of inorganic membrane catalyst: (1) Dissolving 250 grams of zirconium n-butoxide in 250 mL of ethanol to prepare ethanol solution of zirconium n-butoxide; (2) Adding the solution obtained in step (1) dropwise with an aqueous nitric acid solution with a molar concentration of 6 mol / L zirconium n-butoxide ethanol solution to obtain a transparent sol, then add 5g of polyvinyl alcohol and 5g of polyethylene glycol respectively, continue to stir, and further obtain a sol with a certain viscosity, the stirring temperature is 40°C, and the stirring speed is 200r / min; (3) Add α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step b for 1 minute, pull it out at a pulling speed of 10 cm / min, and then heat-treat it at 100°C for 10 minutes, repeat the above steps of dipping, pulling and heat treatment 4 times , and then roasted at 1000°C for 4 hours; (4) impregnate the ceramic tube obtained in step (3) with a concentration of 3mol / L silver nitrate...

Embodiment 3

[0040] Preparation of inorganic membrane catalyst: (1) Dissolving 250 grams of zirconium n-butoxide in 250 mL of ethanol to prepare ethanol solution of zirconium n-butoxide; (2) Adding the solution obtained in step (1) dropwise with an aqueous nitric acid solution with a molar concentration of 6 mol / L zirconium n-butoxide ethanol solution to obtain a transparent sol, then add 4g of polyvinyl alcohol and 4g of polyethylene glycol respectively, continue to stir, and further obtain a sol with a certain viscosity, the stirring temperature is 40°C, and the stirring speed is 200r / min; (3) Add α-Al 2 o 3 Immerse the ceramic tube vertically into the sol obtained in step b for 2 minutes, pull it out at a pulling speed of 10 cm / min, and then heat-treat it at 100°C for 10 minutes, repeat the above steps of dipping, pulling and heat treatment 5 times , and then roasted at 1000°C for 4 hours; (4) impregnate the ceramic tube obtained in step (3) with a concentration of 4mol / L silver nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com