Method for preparing aged Dao dish by adopting direct vat set fungicide

A direct-injection, bacterial agent technology, applied in microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve the problems of difficult product taste, strong wine taste, long fermentation period, etc. , to achieve the effect of blocking the formation of nitrite, strong tolerance and rapid acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the direct injection bacterial agent: after activating the Lactobacillus plantarum, insert 3% of the total volume into the expansion culture medium to continue the cultivation. The components of the expansion culture medium are: 2.5-3.0% of glucose, 0.3-0.6% of yeast powder, and 0.5-1.0% of beef extract. The culture conditions are as follows: the initial pH of the culture medium is 6.0-6.5, the culture temperature is 30-35° C., the rotation speed of the shaker is 80-100 r / min, and the culture time is 12-16 hours. Centrifuge the culture solution after the above expansion at a temperature of 4°C and a speed of 4000r / min for 20 minutes to obtain the bacteria sludge, and add a protective agent. In terms of mass, the ratio of the protective agent to the bacteria sludge is 1: 2-3. Vacuum freeze-drying to obtain bacterial powder. Among them, the protective agent includes the following raw materials in parts by weight: 9 parts of skimmed milk powder, ...

Embodiment 1

[0042] The preparation method of the direct injection bacterial agent: after activating the Lactobacillus plantarum, insert 3% of the total volume into the expansion culture medium to continue the cultivation. The components of the expansion medium are: 2.8% glucose, 0.5% yeast powder, and 0.8% beef extract. The culture conditions are as follows: the initial pH of the medium is 6.2, the culture temperature is 32° C., the rotation speed of the shaker is 100 r / min, and the culture time is 14 hours. Centrifuge the culture solution after the above expansion at a temperature of 4°C and a speed of 4000r / min for 20 minutes to obtain the bacteria sludge, and add a protective agent. In terms of mass, the ratio of the protective agent to the bacteria sludge is 1: 2.5, vacuum freeze-drying to obtain bacterial powder. Among them, the protective agent includes the following raw materials in parts by weight: 9 parts of skim milk powder, 2 parts of trehalose, 0.6 parts of glycerin, 2.5 part...

Embodiment 2

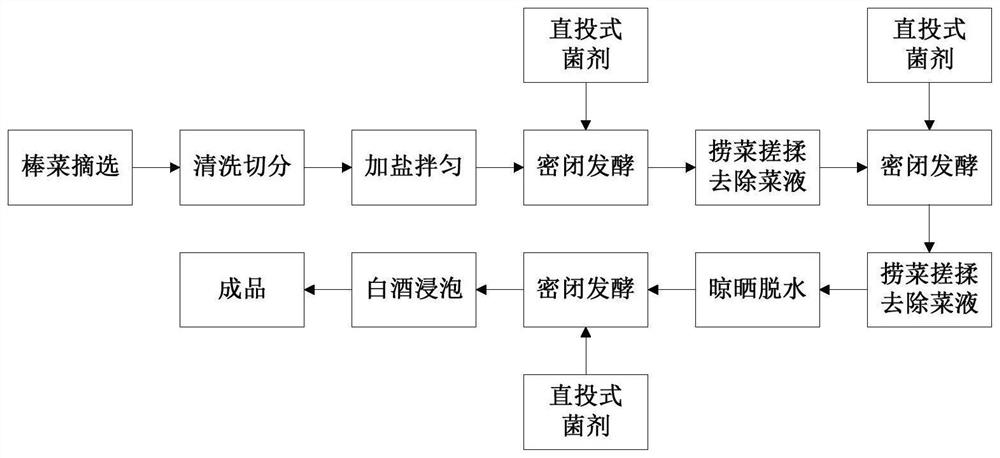

[0050] A kind of method that adopts direct-throwing bacterial agent to make aged dish, concrete steps are as follows:

[0051] (1) Select 3000g of fresh and non-corruption mature stick vegetables, cut off the stem bark of the rod-shaped part with a knife, wash it with clean water, and drain it.

[0052] (2) cut the stick vegetables after step (1) into small pieces with a knife, place them in a large basin, add 240g of edible salt and 0.6g direct-throwing type bacterial agent (the preparation method of the bacterial agent is the same as in Example 1) , mix well and put it in a container such as a jar or a bag, and ferment for 24 hours in an airtight manner.

[0053] (3) Remove the fermented spinach from the container in step (2), discard the liquid in the container, knead it for 1 hour to make the texture of the spinach soft, put it in a large basin, add 1.5g direct-injection bacterial agent, Put it in the container of step (2) after fully mixing, and ferment for 24 hours in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com