Blue passivator for steel parts and preparation method thereof

A passivation agent, blue technology, applied in the direction of metal material coating process, etc., can solve the problems of corrosion resistance, inability to meet industrialization requirements, weak corrosion resistance of passivation layer, etc., to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

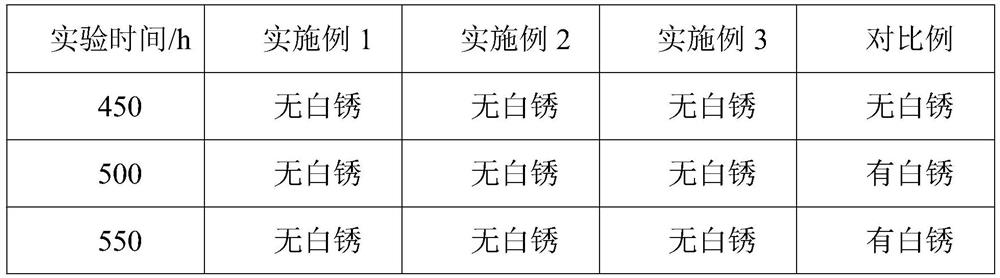

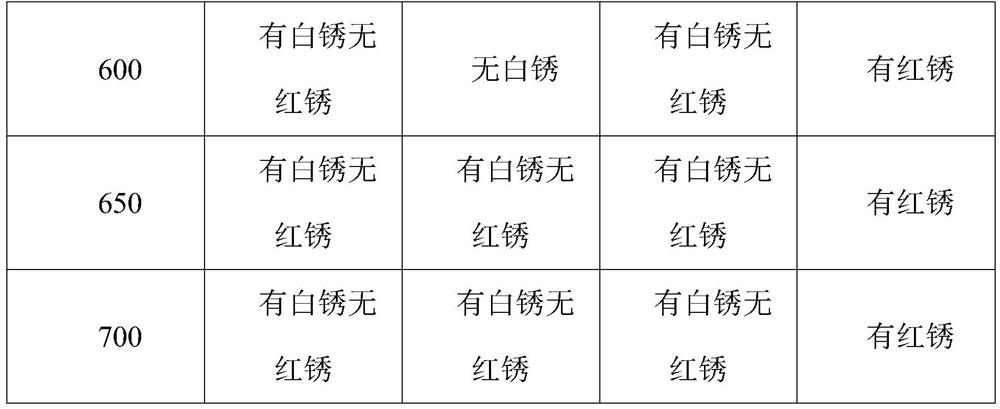

Examples

Embodiment 1

[0013] Embodiment 1, be used for the blue passivating agent of iron and steel parts, comprise following weight parts (kg) raw material: chromium sulfate 150, nano silica sol 80, malonic acid 20, sodium hydroxide 70, cobalt sulfate 100, citric acid 40 , sodium nitrate 10, nitric acid 20, sulfuric acid 30, sodium fluoride 10 and appropriate amount of deionized water.

[0014] The preparation method of the blue passivating agent that is used for iron and steel parts, comprises the following steps:

[0015] Ⅰ Mix chromium sulfate, citric acid, malonic acid, nitric acid, sulfuric acid and deionized water, heat to 75°C, keep it warm for 3 hours, then let it stand and cool to 20°C;

[0016] Ⅱ Add sodium hydroxide, sodium nitrate, sodium fluoride, stir and mix well;

[0017] Ⅲ Adjust the temperature of the mixed solution to 25°C, add cobalt sulfate and nano-silica sol, stir for 8 minutes, and let stand for 2 hours.

Embodiment 2

[0018] Embodiment 2, be used for the blue passivating agent of iron and steel parts, comprise following weight parts (kg) raw material: chromium sulfate 185, nano silica sol 100, malonic acid 25, sodium hydroxide 75, cobalt sulfate 110, citric acid 45 , 15% sodium nitrate, 25% nitric acid, 35% sulfuric acid, 15% sodium fluoride and an appropriate amount of deionized water.

[0019] The preparation method of the blue passivating agent that is used for iron and steel parts, comprises the following steps:

[0020] Ⅰ Mix chromium sulfate, citric acid, malonic acid, nitric acid, sulfuric acid and deionized water, heat to 80°C, keep warm for 3.5h, then let stand and cool to 25°C;

[0021] Ⅱ Add sodium hydroxide, sodium nitrate, sodium fluoride, stir and mix well;

[0022] Ⅲ Adjust the temperature of the mixed solution to 30°C, add cobalt sulfate and nano-silica sol, stir for 10 minutes, and let stand for 2.5 hours.

Embodiment 3

[0023] Embodiment 3, be used for the blue passivating agent of iron and steel parts, comprise following weight parts (kg) raw material: chromium sulfate 220, nano silica sol 120, malonic acid 30, sodium hydroxide 80, cobalt sulfate 120, citric acid 50 , sodium nitrate 20, nitric acid 30, sulfuric acid 40, sodium fluoride 20 and appropriate amount of deionized water.

[0024] The preparation method of the blue passivating agent that is used for iron and steel parts, comprises the following steps:

[0025] Ⅰ Mix chromium sulfate, citric acid, malonic acid, nitric acid, sulfuric acid and deionized water, heat to 85°C, keep it warm for 4 hours, then let it stand and cool to 30°C;

[0026] Ⅱ Add sodium hydroxide, sodium nitrate, sodium fluoride, stir and mix well;

[0027] Ⅲ Adjust the temperature of the mixed solution to 35°C, add cobalt sulfate and nano-silica sol, stir for 12 minutes, and let stand for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com