High-strength and high-heat-resistance bio-based polyamide composition and preparation method thereof

A bio-based polyamide, high heat-resistant technology, applied in the high-heat-resistant bio-based polyamide composition and its preparation, high strength field, can solve the long-term thermal oxygen aging of bio-based polyamide, limit the polyamide composition Issues such as the scope of application and the inability to objectively reflect the performance of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-20 and comparative example 1-18

[0047] The preparation method of embodiment 1-20 and comparative example 1-18:

[0048] Preparation of bio-based polyamide compositions:

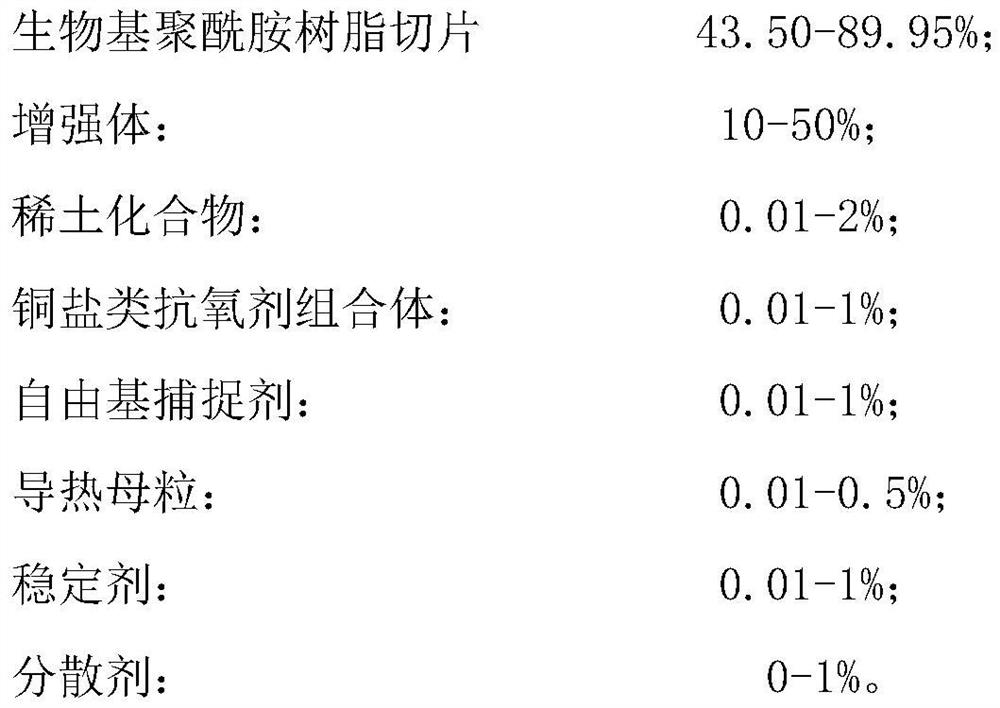

[0049] Weigh the dried raw materials according to the proportion of the formula; pass the bio-based polyamide resin chip, rare earth metal, copper salt antioxidant combination, free radical scavenger, thermal conductive masterbatch, processing stabilizer and dispersant through a high-speed mixer Then mix evenly, weigh the reinforcing body according to the proportion, add the above-mentioned resin and additive mixed raw materials through the main feeding port of the twin-screw extruder, add the reinforcing body from the side feeding port of the twin-screw extruder, and pass through the double-screw extruder. The high-strength, high-heat-resistant bio-based polyamide composition is obtained after the processes of melt extrusion at 220-300° C., granulation, and drying treatment by a screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com