A kind of high-content high-pigment carbon black-thermoplastic polyester masterbatch and preparation method thereof

A high-pigment carbon black and thermoplastic polyester technology, applied in the field of polymer materials, can solve the problems of fiber physical performance decline, poor light resistance and heat resistance, difficult dispersion, etc., to enhance blackness and gloss, and improve dispersion effect, the effect of reducing alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

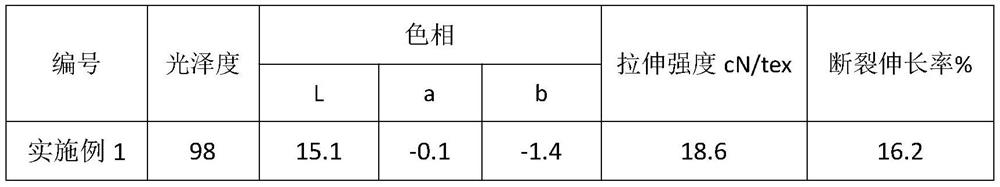

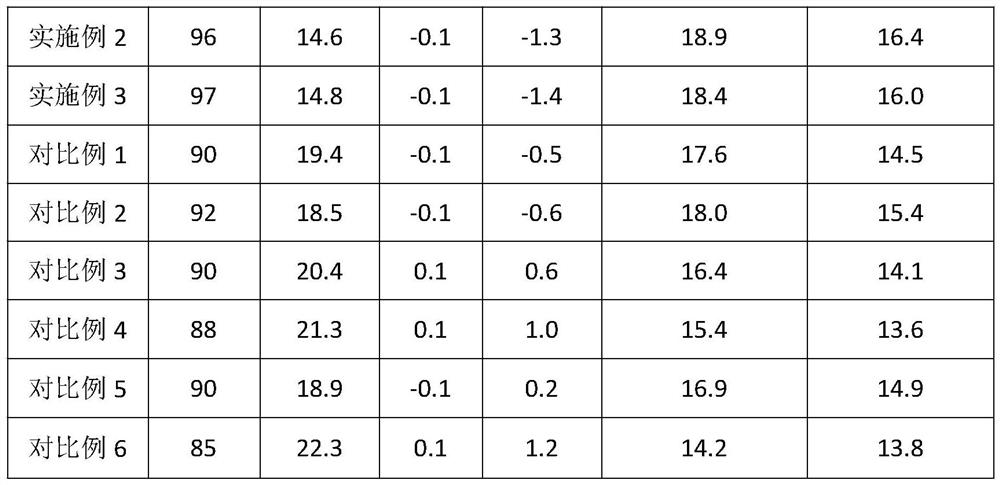

Examples

preparation example Construction

[0050] 1.2 dispersant preparation

[0051] 1.2.1 Preparation of Dispersant I, including the following steps:

[0052] (1) According to the weight of the reaction, 20 parts of stearic acid, 40 parts of caprolactone, 8 parts of blenedhenic acid, 20 parts of succinic acid, 8 dihydroxymethyl proppropionic acid, 10 new pentanediol 10, two 8 parts of alcohol, 3 parts of trihydroxyethyl isocyanrate, 15 parts of diphenyl methane diisocyanate, 8 parts of N, N-dimethylamine, 0.04 of tetrabutyl titanate, and 80 dimetarades;

[0053] (2) Adding stearic acid, succinic acid, new pentanediol, ethylene glycol, trihydroxyethyl isotide, 1 / 2 weight of xylene and tetrabutyl tetrabutyl tetrabut, into the reactor, Nitrogen is warmed to 180 ° C, the insulation reaction is 10 h, and the moisture is continuously excluded through the water supply during the reaction; then adding hexylolide, dihydroxymethyl propionic acid, and heats up nitrogen temperature to 220 ° C, heat insulation reaction for 6 h, and t...

Embodiment 1

[0064] In this example, a high content of high-panel carbon black-thermoplastic polyester pellets, including the following weight of the following weight: 60 parts of high-color carbon carbon, 80 parts of thermoplastic polyester, 3 carbon nanofibers, 10 dispersants, 5 parts of the silane coupling agent, 0.9 parts of an antioxidant.

[0065] The high pigment carbon black is pre-passing ozone oxidative modification, the particle size is 10-25 nm, the specific surface area is 400-700m 2 / g, the oil absorption value is <1.5 mL / g, the volatile content reaches 4.5-6.5 wt%.

[0066] The acid value of the thermoplastic polyester is 40 mgKOH / g, the melt index (230 ° C / 2.16 kg) is 30 g / 10 min; characteristic viscosity is 0.8 dl / g.

[0067] The carbon nanofibers have a diameter of from 10 to 20 nm, and the length is 10-50 μm;

[0068] The dispersant is a dispersant I, and the silane coupling agent is gamma-aminopropyltriethoxysilane (KH550), and an antioxidant is a hindered phenol...

Embodiment 2

[0079] In this example, a high content of high-pose carbon black-thermoplastic polyester pellets, including the following weight of the following weight: 50 parts of high-patronic carbon, 2 parts of thermoplastic polyester 40, carbon nanofibers, 12 parts of dispersant, silane 8 parts of the coupling agent, 1 antioxidant;

[0080] The high-pig carbon black pre-primary isoxitic oxidation modification, the particle size is 10-25 nm, the specific surface area is 400-700m 2 / g, the oil absorption value is <1.5 ml / g, the volatile content is 4.5-6.5% by weight;

[0081] The acid value of the thermoplastic polyester was 50 mgKOH / g, the melt index (230 ° C / 2.16 kg) was 25 g / 10 min; characteristic viscosity was 0.6 dl / g.

[0082]The carbon nanofibers have a diameter of from 10 to 20 nm, and the length is 10-50 μm;

[0083] The dispersing agent is a dispersant II, and the silane coupling agent is gamma-glycidyl ether oxyltrimethoxysilane (KH560), an antioxidant is a hindered amine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com