Method for preparing hierarchical pore SAPO-20 molecular sieve from illite

A SAPO-20, illite technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate and other directions, can solve the problem that the research of hierarchical porous SAPO-20 molecular sieve has not yet been reported, and achieves the goal of reducing synthesis cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

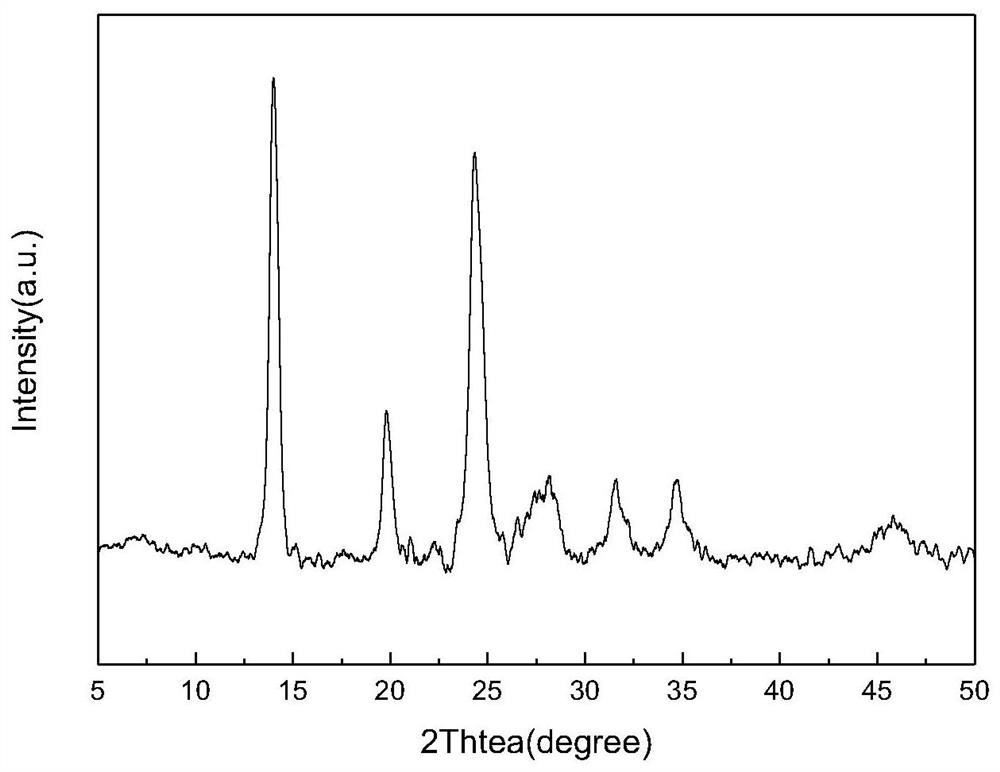

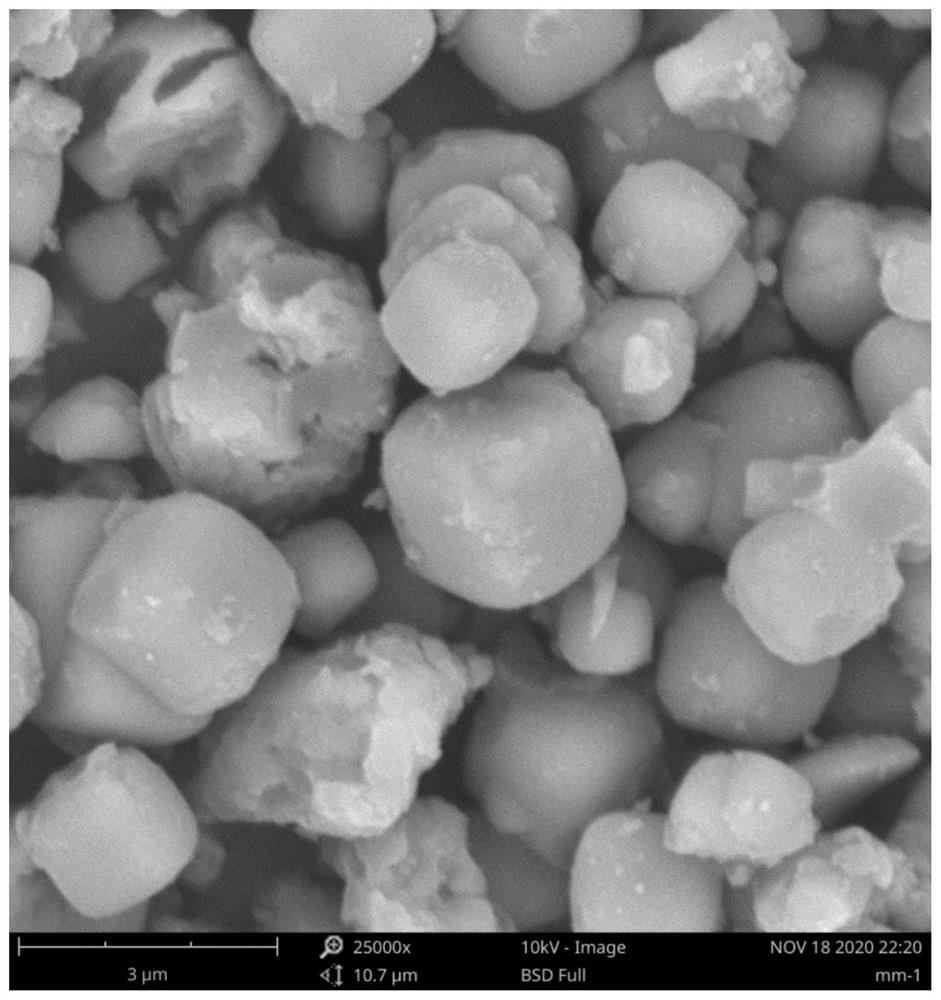

Image

Examples

Embodiment 1

[0042] The illite that present embodiment provides prepares the method for hierarchical porous SAPO-20 molecular sieve comprising:

[0043] 1) Calcining and activating illite minerals and sodium carbonate powder, cooling and grinding to obtain activated illite;

[0044] The activation process is that the mass ratio of illite minerals to sodium carbonate is 1:0.6, the calcination temperature is 600°C, the calcination time is 90min, and the particle size of illite raw ore is 100 mesh. Grinding after cooling to obtain activated illite;

[0045] 2) Mix activated illite and 2mol / L hydrochloric acid at a mass volume ratio of 1:13.5mL, stir in a water bath at 80°C for 4 hours, centrifuge, wash, and dry to obtain activated illite silica slag with a purity ≥ 65%;

[0046] 3) Activated illite silica slag, aluminum source, phosphorus source, water, microporous template agent and mesoporous template agent are made into slurry, and the pH value is maintained at 9; the molar ratio of each ...

Embodiment 2

[0052] The method that utilizes illite to prepare microporous SAPO-20 molecular sieve that the present embodiment provides comprises:

[0053] 1) Calcining and activating illite minerals and sodium carbonate powder, cooling and grinding to obtain activated illite;

[0054] The activation process is that the mass ratio of illite minerals to sodium carbonate is 1:0.8, the calcination temperature is 900°C, the calcination time is 60min, and the particle size of illite raw ore is 200 mesh. Grinding after cooling to obtain activated illite;

[0055] 2) Mix activated illite and 2mol / L hydrochloric acid at a mass volume ratio of 1:13.5mL, stir in a water bath at 95°C for 3 hours, centrifuge, wash, and dry to obtain activated illite silica slag with a purity ≥ 65%;

[0056] 3) The activated illite silicon slag is made into slurry with aluminum source, phosphorus source, water, microporous template agent and mesoporous template agent, and the pH value is maintained at 6; the molar rat...

Embodiment 3

[0062] The method that utilizes illite to prepare microporous SAPO-20 molecular sieve that the present embodiment provides comprises:

[0063] 1) Calcining and activating illite minerals and sodium carbonate powder, cooling and grinding to obtain activated illite;

[0064] The activation process is that the mass ratio of illite minerals to sodium carbonate is 1:1.2, the calcination temperature is 700°C, the calcination time is 90min, and the particle size of illite raw ore is 300 mesh. Grinding after cooling to obtain activated illite;

[0065] 2) Mix activated illite and 2mol / L hydrochloric acid at a mass volume ratio of 1:13.5mL, stir in a water bath at 85°C for 3.5h, centrifuge, wash and dry to obtain activated illite silica slag with a purity ≥ 65%;

[0066] 3) Activated illite silicon slag, aluminum source, phosphorus source, water, microporous template and mesoporous template are made into slurry, and the pH value is kept at 7; the molar ratio of each substance in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com