Method for preparing nitrogen-doped carbon material by utilizing fluorine-containing macromolecules

A nitrogen-doped carbon and polymer technology, applied in chemical instruments and methods, carbon preparation/purification, catalyst activation/preparation, etc., can solve problems such as difficult to control the type of nitrogen doping, to achieve environmental protection and waste Utilization, low cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Preparation of mixed slurry. The fluorine-containing polymer precursor material and the solvent are mixed to obtain a mixed solution. The above-mentioned fluorine-containing polymer precursor material is a polymer whose relative molecular weight is between 10 million and 10 million, and part of hydrogen is replaced by fluorine. Wherein, the solvent is at least one selected from at least one of N-methylpyrrolidone, chloroform, water and ethanol. The concentration of the mixed solution may be 5-100 mg / mL. Preferably, a templating agent is also added to the mixed solution. The template agent is selected from at least one of mesoporous silica, molecular sieve, and magnesium oxide. The mass ratio of the template agent to the fluorine-containing polymer precursor material can be (0.1-5):1. After calcination, an etchant (an acid solution corresponding to the template agent) is used to remove the template agent.

[0059] Soak the conductive carbon felt in the obtained mixe...

Embodiment 1

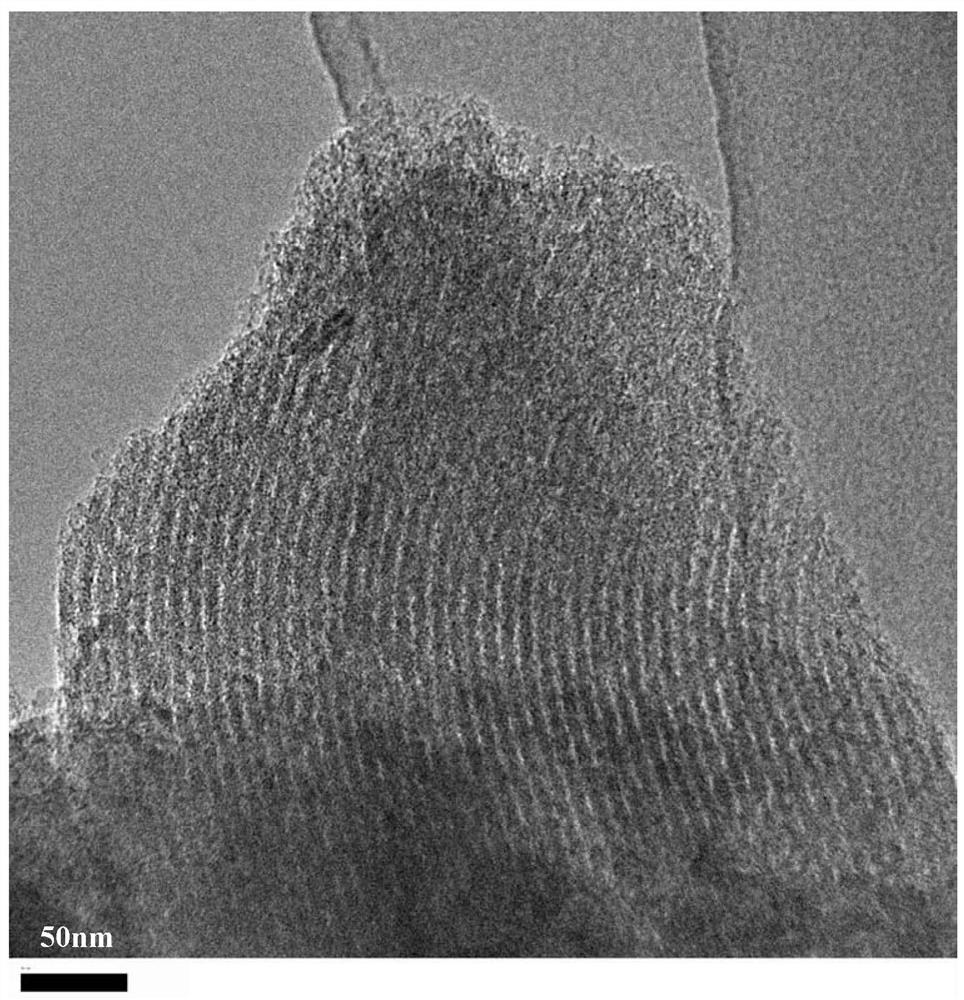

[0065] Weigh 0.5g of polyvinylidene fluoride (PVDF) powder sample, spread evenly in the corundum porcelain boat, and then place it in the tube atmosphere furnace, then connect the two ends of the tube atmosphere furnace with special flanges and introduce ammonia The flow rate of ammonia gas is 300mL / min, and ammonia gas is fed continuously at this flow rate during the subsequent calcination process. The tail gas is absorbed by sulfuric acid solution to prevent air pollution. After ventilation at room temperature for at least 60 minutes, turn on the program heating, and then turn on the program heating at 20 The heating rate of ℃ / min is raised to 700 ℃, and then the heating is stopped after 4 hours of heat preservation, and the temperature is naturally lowered. After the temperature drops to room temperature, the ammonia gas is stopped and the argon gas with a flow rate of 300mL / min is passed in for at least 60 minutes. Stop, take out the corundum porcelain boat containing the p...

Embodiment 2

[0067] Weigh 0.5g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) powder sample, spread it evenly in a corundum porcelain boat, and then place it in a tube-type atmosphere furnace. The ammonia gas flow rate is 300mL / min, and the ammonia gas is continuously fed at this flow rate during the subsequent calcination process. The tail gas is absorbed by the sulfuric acid solution to prevent air pollution. After aeration at room temperature for at least 60 minutes Turn on the heating program, raise the temperature to 700°C at a heating rate of 20°C / min, then stop heating after holding the temperature for 4 hours, and let the temperature drop naturally. After the temperature drops to room temperature, stop feeding ammonia and feed argon with a flow rate of 300mL / min , stop after at least 60 minutes, take out the corundum porcelain boat containing the product to get black amorphous porous nitrogen-doped carbon material powder, the product has a nitrogen content of 10% and a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com