Preparation method of frost-inhibiting and defrosting super-hydrophobic surface structure

A technology of super-hydrophobic surface and topological structure, which is applied in the direction of surface coating liquid device, special surface, metal material coating process, etc., can solve the problems of inability to process in large batches, high economic cost, etc., and reduce the frost layer Coverage, avoiding secondary icing, simple and economical surface processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

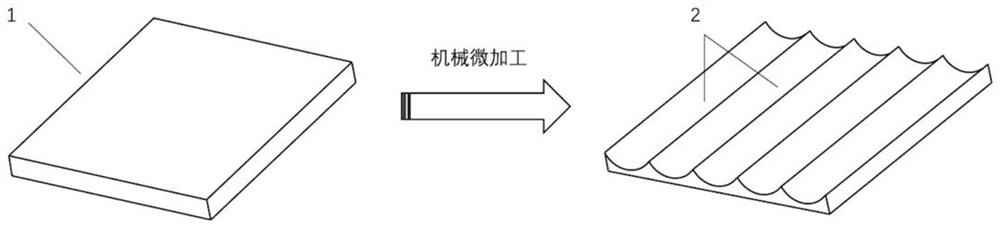

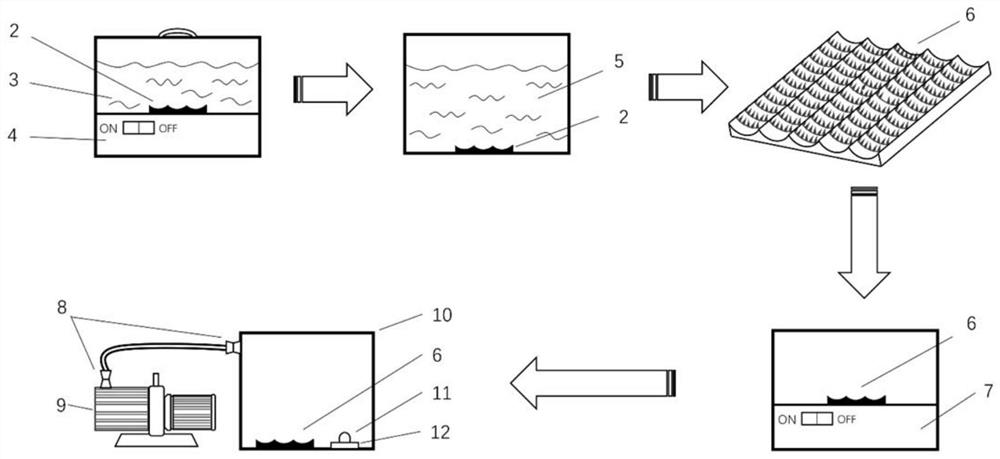

[0031] Take a piece of 2mm thick, 4×4cm 2 Taking the smooth copper sample as an example, the preparation process of superhydrophobic sample 16 is as follows figure 1 , figure 2 shown.

[0032] Step (1): Take a 2mm thick piece, 4×4cm 2 The smooth pure copper sheet 1 was processed by micromachining on the mirror surface with an array of circular arc grooves with a central angle of 120° and an arc length of 500 μm to obtain a sample 2 with an array of micron-scale arc grooves.

[0033] Step (2): Completely immerse the sample 2 having the array of micron-scale arc grooves processed in step (1) in the acetone solution 3 , and perform ultrasonic cleaning for 10 minutes by an ultrasonic cleaning machine 4 . Subsequently, the ultrasonically cleaned samples were rinsed with isopropanol (IPA) and deionized water in sequence, and dried with clean nitrogen.

[0034] Step (3): Soak the sample 2 with the array of micron-scale arc grooves treated in step (2) in NaClO at 96±3°C 2 , NaOH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com