Carbon-based solid acid catalyst, preparation method and method for applying carbon-based solid acid catalyst to biomass hydrothermal conversion

A carbon-based solid acid and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of restricting large-scale industrial applications, easy loss of catalysts, expensive raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

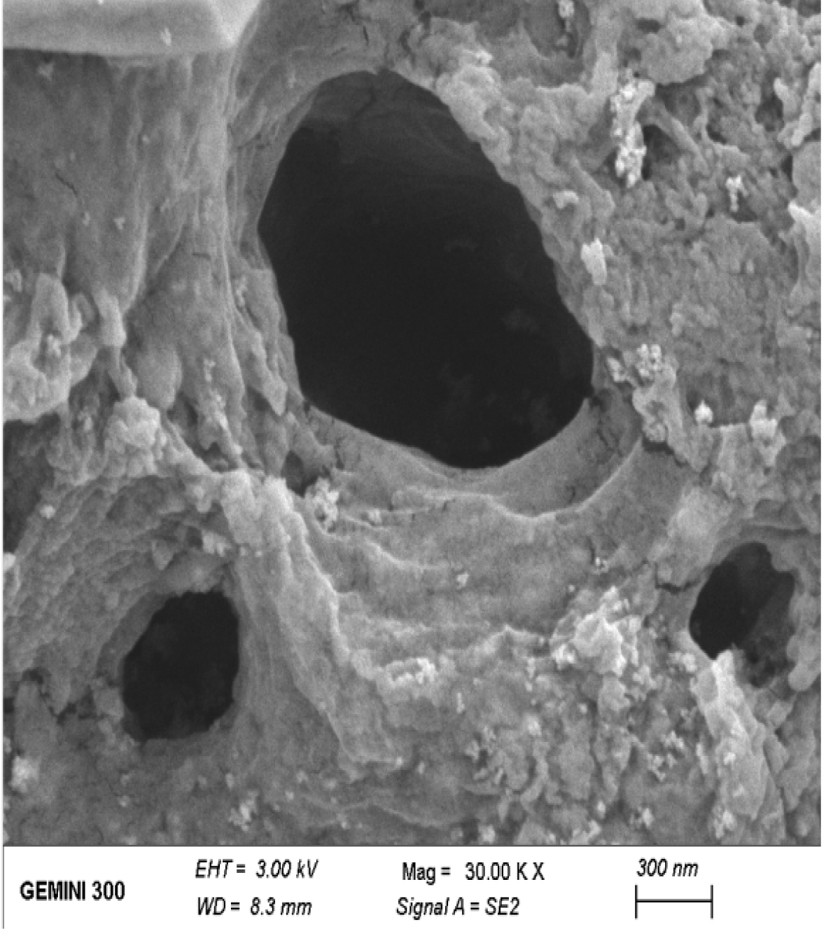

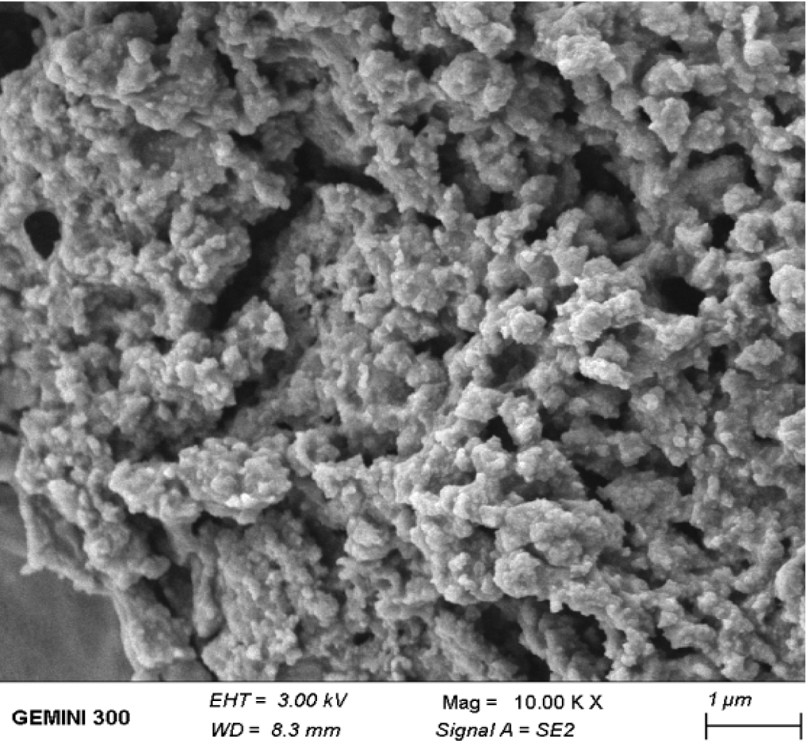

[0050] The present invention proposes a preparation method of a carbon-based solid acid catalyst, which uses pectin as a carbon-based precursor, mixes pectin and an ionic resin of an aromatic ring matrix in a medium and then dries it, then pyrolyzes the dried product, and uses Concentrated sulfuric acid is subjected to sulfonation treatment to obtain a carbon-based solid acid catalyst. Include the following steps:

[0051] S1. mix pectin with water, then add sulfuric acid to activate, and then add the mixture to the ion resin of the aromatic ring matrix;

[0052] S2. drying the obtained product in step S1, pulverizing the obtained material into powder, and pyrolyzing it under dry inert gas;

[0053] S3. Sulfonating the solid obtained after pyrolysis in step S2 with concentrated sulfuric acid;

[0054] S4. Dilute the obtained product of step S3 with water and filter, and the filter residue after filtration is washed with water until no sulfate ion is detected in the washing w...

Embodiment 1

[0071] 8g of dried orange peel pectin was mixed with 30ml of deionized water, then 1ml of concentrated sulfuric acid (98%) was added, and then the mixture was slowly added to the pre-dried 8g of Amberlyst 15 ion resin. After drying at 110–120 °C for 48 h, the resulting black substance was pyrolyzed in a horizontal tube furnace for 1 h at 300 °C under dry nitrogen. With concentrated sulfuric acid (1 g solid / 5g H 2 SO 4 ) at 80°C for 24 h of sulfonation treatment, and the heating equipment is an oil bath with magnetic stirring. After diluting with a large amount of deionized water, the obtained black matter was collected by filtration and washed several times with deionized water until sulfate ions were no longer detected in the washing water. The resulting black solid was dried in an oven at 80°C for 24 hours. Take 0.05g of the obtained black solid in a 10ml test tube, add 0.1g of xylose and 5ml of γ-valerolactone, react under microwave heating conditions for 1h, and at a re...

Embodiment 2

[0078] 8g of dried orange peel pectin was mixed with 30ml of deionized water, then 1ml of concentrated sulfuric acid (98%) was added, and then the mixture was slowly added to the pre-dried 8g of Amberlyst 15 ion resin. After drying at 110–120 °C for 48 h, the resulting black substance was pyrolyzed in a horizontal tube furnace for 1 h at 300 °C under dry nitrogen. With concentrated sulfuric acid (1 g solid / 5g H 2 SO 4 ) was subjected to sulfonation treatment at 100°C for 24 h, and the heating equipment was an oil bath with magnetic stirring. After diluting with a large amount of deionized water, the obtained black matter was collected by filtration and washed several times with deionized water until sulfate ions were no longer detected in the washing water. The resulting black solid was dried in an oven at 80°C for 24 hours. Take 0.05 g of the obtained black solid in a 10 ml test tube, add 0.1 g of xylose and 5 ml of γ-valerolactone, and react under microwave heating condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com