Modified polyphenyl ether resin, polyphenyl ether composite material, preparation method thereof and printed circuit board

A polyphenylene ether resin, composite material technology, applied in the direction of printed circuits, printed circuits, circuit substrate materials, etc., can solve the problem of poor results, reduce the heat resistance and dielectric properties of the resin system, and the flame retardancy and resistance of PPO resins. Problems such as poor thermal properties, to achieve the effect of ensuring mechanical properties and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

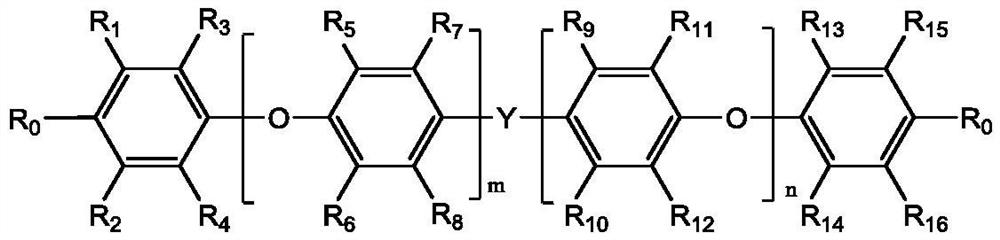

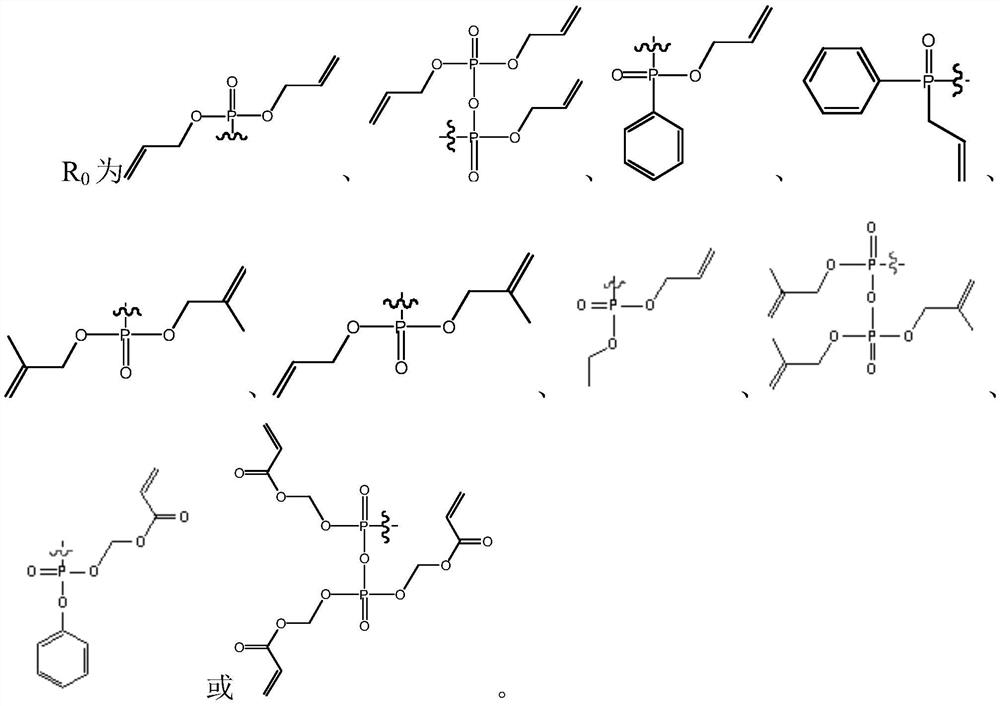

[0063] In one of the specific embodiments, the preparation method of the modified polyphenylene ether resin comprises the following steps:

[0064] Preparation of the monomer 1: dissolving the phosphorus-containing compound in an organic solvent, adding the vinyl-containing alcohol compound under alkaline conditions, and performing a substitution reaction to obtain the monomer 1;

[0065] Preparation of the modified polyphenylene ether resin: mixing the monomer 1 and the polyphenylene ether resin, and performing a substitution reaction under the action of a catalyst.

[0066] In one of the specific embodiments, in the preparation of the monomer 1, the molar ratio of the chlorine group in the phosphorus-containing compound to the hydroxyl group in the vinyl-containing alcohol compound is greater than 1; thus making the The chlorine group in the phosphorus-containing compound will not completely react with the hydroxyl group in the vinyl-containing alcohol compound, so that the ...

Embodiment 1

[0088] This embodiment is a modified polyphenylene ether resin, and its raw materials and preparation methods are as follows:

[0089]

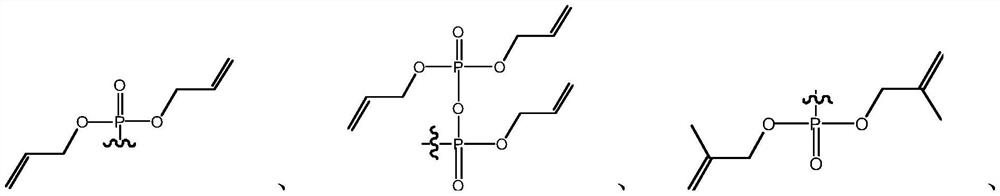

[0090] 1) Dissolve phosphorus oxychloride (15.33g, 0.1mol) in 100mL tetrahydrofuran, stir well under nitrogen atmosphere and ice bath, add triethylamine (32g) and tetrahydrofuran 20mL mixed solution to react for 10 minutes, add dropwise A mixed solution of allyl alcohol (11.62 g, 0.2 mol) and 50 mL of tetrahydrofuran was added dropwise and continued to react for 4 h.

[0091] 2) Then add CuCl (0.03g) into the reaction solution, heat up to 68°C and reflux, add a solution of dihydroxy-terminated polyphenylene ether oligomer SA90 (average molecular weight 1600g / mol, 72g, 0.045mol) and 30mL of tetrahydrofuran to continue React for 4 hours.

[0092] 3) After the reaction is completed, cool to room temperature, and filter the precipitated triethylamine hydrochloride. Rotary evaporation removes residual solvent and unreacted substances, followe...

Embodiment 2

[0094] This embodiment is a modified polyphenylene ether resin, and its raw materials and preparation methods are as follows:

[0095]

[0096] 1) Dissolve pyrophosphoryl chloride (25.17g, 0.1mol) in 100mL tetrahydrofuran, stir well under nitrogen atmosphere and ice bath, add triethylamine (32g) and tetrahydrofuran 20mL mixed solution to react for 10 minutes, add propylene dropwise A mixed solution of alcohol (17.42 g, 0.3 mol) and THF 50 mL was added dropwise and continued to react for 4 h.

[0097] 2) Then add CuCl (0.05g) into the reaction solution, heat up to 68°C and reflux, add a solution of dihydroxy-terminated polyphenylene ether oligomer SA90 (average molecular weight 1600g / mol, 72g, 0.045mol) and 30mL of tetrahydrofuran to continue React for 4 hours.

[0098] 3) After the reaction is completed, cool to room temperature, and filter the precipitated triethylamine hydrochloride. Rotary evaporation removed residual solvent and unreacted substances, followed by deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com