Preparation method of rare earth cerium doped gallium oxide nano material

A nano-material, gallium oxide technology, applied in the field of rare earth doping production, can solve the problems of high production equipment requirements and complicated preparation process, and achieve the effect of low equipment requirements, simple process steps and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

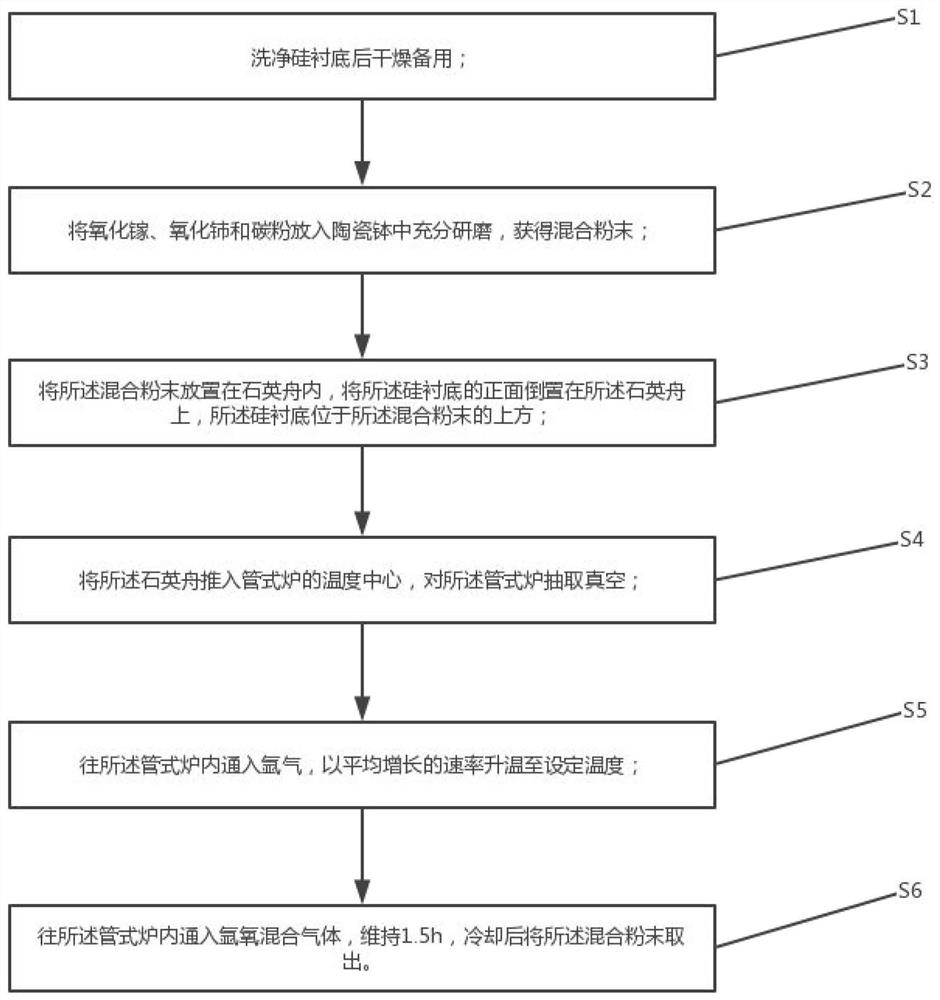

[0031] see figure 1 , the invention provides a preparation method of rare earth cerium-doped gallium oxide nanomaterials, comprising the following steps:

[0032] S1: Clean the silicon substrate and dry it for later use;

[0033] S2: Put gallium oxide, cerium oxide and carbon powder into a ceramic bowl to fully grind to obtain a mixed powder;

[0034] S3: placing the mixed powder in a quartz boat, inverting the front side of the silicon substrate on the quartz boat, and the silicon substrate is located above the mixed powder;

[0035] S4: push the quartz boat into the temperature center of the tube furnace, and draw a vacuum to the tube furnace;

[0036] S5: Introduce argon gas into the tube furnace, and raise the temperature to the set temperature at an average increasing rate;

[0037] S6: Pass argon-oxygen mixed gas into the tube furnace for 1.5 hours, and take out the mixed powder after cooling.

[0038] Further, in the process of drying the silicon substrate after cle...

specific Embodiment 1

[0048] S101: ultrasonically clean the silicon substrate with acetone, ethanol and deionized water for 10 min respectively in sequence, then blow dry with nitrogen gas, wash and dry for later use;

[0049] S102: according to the ratio of the amount of gallium oxide / cerium oxide being 9.5:0.5, the powder mixed in the ceramic bowl is fully ground together with carbon powder according to the ratio of 1:2 to obtain the first mixed powder;

[0050] S103: placing the above-mentioned first mixed powder in a quartz boat, and then placing the silicon substrate pretreated in step S101 at a position 1.2 cm above the mixed powder in the quartz boat;

[0051] S104: Then push the quartz boat to the temperature center of the tube furnace, tighten the channel, pump argon after vacuuming, raise the temperature to 1150°C at a rate of 10°C / min, and pass in a mixed gas with an argon-oxygen ratio of 2:1, After maintaining for 1.5h, take it out after cooling with the furnace. Wherein the gas flow v...

specific Embodiment 2

[0054] S201: ultrasonically clean the silicon substrate with acetone, ethanol and deionized water for 10 min respectively in sequence, then blow dry with nitrogen gas, wash and dry for later use;

[0055] S202: According to the ratio of the amount of gallium oxide / cerium oxide being 9.5:0.5, the powder mixed in the ceramic bowl is fully ground together with carbon powder according to the ratio of 1:2 to obtain the second mixed powder;

[0056] S203: placing the above-mentioned second mixed powder in a quartz boat, and then placing the silicon substrate pretreated in step S201 at a position 1.2 cm above the mixed powder in the quartz boat;

[0057]S204: Then push the quartz boat to the temperature center of the tube furnace, tighten the channel, pump argon after vacuuming, raise the temperature to 1100°C at a rate of 10°C / min, and pass in a mixed gas with an argon-oxygen ratio of 2:1, After maintaining for 1.5h, take it out after cooling with the furnace. Wherein the gas flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com