Welding method for thick-wall alloy pipeline of needle coke device

A welding method and needle coke technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as high-altitude quenching tendency, difficulty in ensuring welding quality, and welding cold cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A welding method for a thick-walled alloy pipe of a needle coke device, wherein the material of the alloy pipe is 1Cr5Mo, comprising the following steps:

[0028] Step 1: Material selection: select the welding wire and electrode with the same alloy composition as the pipe material to be welded;

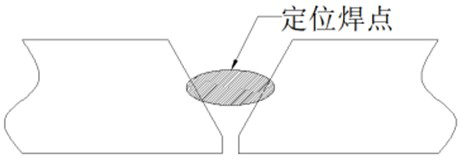

[0029] Step 2: Groove preparation and joint alignment: process the groove on the end of the pipe to be welded, and group the grooves between two adjacent pipes, and control the gap between the groups at 2.5 mm;

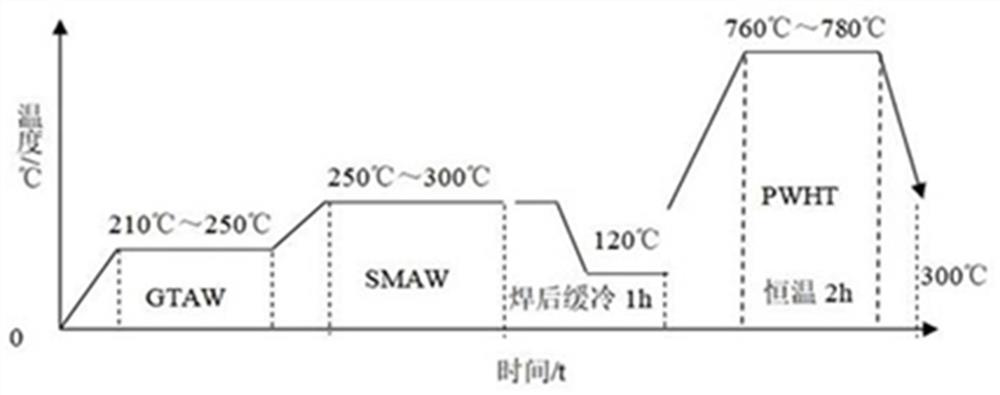

[0030] Step 3: Preheating before welding, the preheating temperature is controlled between 250°C, and the heating range is at least 100mm on both sides of the weld;

[0031] Step 4: Multi-layer and multi-pass welding: multi-layer and multi-pass welding is adopted during the welding process, the thickness of each layer of weld bead is ≤3mm, and the width of each weld seam is ≤8mm; the interlayer temperature during the welding process is not lower than the ...

Embodiment 2

[0040] Embodiment 2: A welding method of a thick-walled alloy pipe of a needle coke device, the material of the alloy pipe is 1Cr5Mo, comprising the following steps:

[0041] Step 1: Material selection: select the welding wire and electrode with the same alloy composition as the pipe material to be welded;

[0042] Step 2: Groove preparation and joint alignment: process the groove on the end of the pipe to be welded, and group the grooves between two adjacent pipes, and control the gap between the groups to 3.0mm;

[0043] Step 3: Preheating before welding, the preheating temperature is controlled between 280°C, and the heating range is at least 100mm on both sides of the weld;

[0044] Step 4: Multi-layer and multi-pass welding: multi-layer and multi-pass welding is adopted during the welding process, the thickness of each layer of weld bead is ≤3mm, and the width of each weld seam is ≤8mm; the interlayer temperature during the welding process is not lower than the preheating...

Embodiment 3

[0053] Embodiment 3: A welding method for a thick-walled alloy pipe of a needle coke device, wherein the material of the alloy pipe is 1Cr5Mo, comprising the following steps:

[0054] Step 1: Material selection: select the welding wire and electrode with the same alloy composition as the pipe material to be welded;

[0055] Step 2: Groove preparation and joint alignment: process the groove on the end of the pipe to be welded, and group the grooves between two adjacent pipes, and control the gap between the groups to 3.5 mm;

[0056] Step 3: Preheating before welding, the preheating temperature is controlled between 300°C, and the heating range is at least 100mm on both sides of the weld;

[0057] Step 4: Multi-layer and multi-pass welding: multi-layer and multi-pass welding is adopted during the welding process, the thickness of each layer of weld bead is ≤3mm, and the width of each weld seam is ≤8mm; the interlayer temperature during the welding process is not lower than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com