Industrial tail gas low-temperature denitration method and system

A technology for low-temperature denitrification and industrial tail gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as catalyst poisoning and deactivation, and achieve the effects of improved low-temperature efficiency, simple preparation process, and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

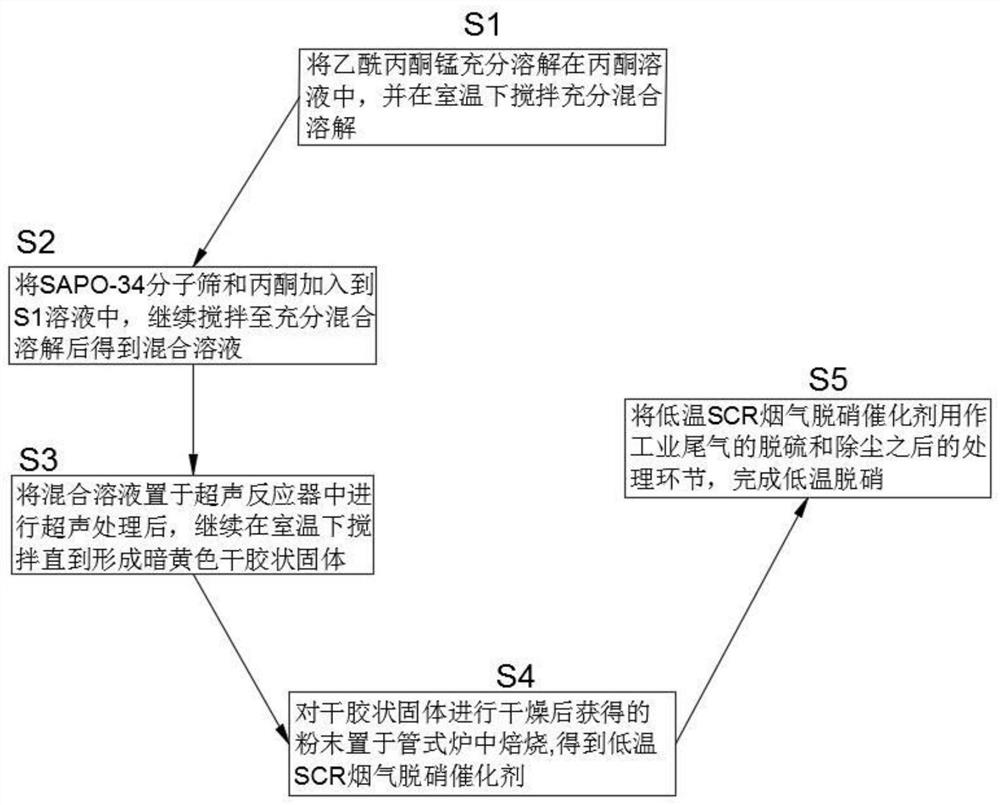

[0038] This embodiment discloses as figure 1 A low-temperature denitrification method for industrial tail gas shown, comprising the following steps:

[0039] S1 Fully dissolve manganese acetylacetonate in acetone solution, and stir at room temperature to fully mix and dissolve;

[0040] S2 adds SAPO-34 molecular sieve and acetone to the S1 solution, and continues to stir until fully mixed and dissolved to obtain a mixed solution;

[0041] S3 places the mixed solution in an ultrasonic reactor for ultrasonic treatment, and continues to stir at room temperature until a dark yellow dry gelatinous solid is formed;

[0042] S4 drying the colloidal solid and drying the powder obtained in a tube furnace to obtain a low-temperature SCR flue gas denitrification catalyst;

[0043] S5 uses low-temperature SCR flue gas denitrification catalyst as the treatment link after desulfurization and dust removal of industrial tail gas to complete low-temperature denitrification.

[0044] In this...

Embodiment 2

[0051] This embodiment discloses the reaction steps when performing denitrification treatment:

[0052] T1 reaction components are transferred from the fluid body to the outer surface of the solid catalyst;

[0053] T2 reaction components are transferred from the outer surface of the catalyst to the inner surface of the catalyst;

[0054] T3 reaction components are adsorbed on the surface of the catalyst;

[0055] T4 reaction components undergo chemical reactions on the catalyst surface;

[0056] The T5 reaction product is desorbed on the catalyst surface;

[0057] The T6 reaction product is transferred from the inner surface of the catalyst to the outer surface of the catalyst;

[0058] The T7 reaction product is transferred from the outer surface of the catalyst to the main body of the fluid.

[0059] In this embodiment, when the conditions of flue gas entering the SCR reactor, such as flue gas flow rate, temperature, composition, etc., reach the predetermined working co...

Embodiment 3

[0070] This embodiment discloses a low-temperature denitrification system for industrial tail gas, which includes an SCR reactor, a thermocouple, a pressure transmitter, a catalyst injection device, a flue gas measurement device, and an electrical control assembly.

[0071] In summary, the present invention uses the SCR flue gas denitrification catalyst, its thermal stability is greatly improved, and it is effective in catalytic removal of NO X The low temperature efficiency is greatly improved, the preparation process of the SCR flue gas denitrification catalyst of the present invention is simple, and the surface active groups are complex, and its NO X The adsorption capacity is higher, and higher adsorption efficiency can be achieved at high space velocity. At the same time, the SCR flue gas denitrification catalyst of the present invention has a well-developed pore structure and a relatively large inner surface. Because the chemical reaction of gas components must be carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com