A method for manufacturing a multi-material porous distal femur implant

A manufacturing method and multi-material technology, applied in the field of additive manufacturing, can solve problems such as the inability to truly realize the function of cartilage, easy stress shielding, and high brittleness of implants, so as to reduce stress shielding, improve flexural performance, The effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

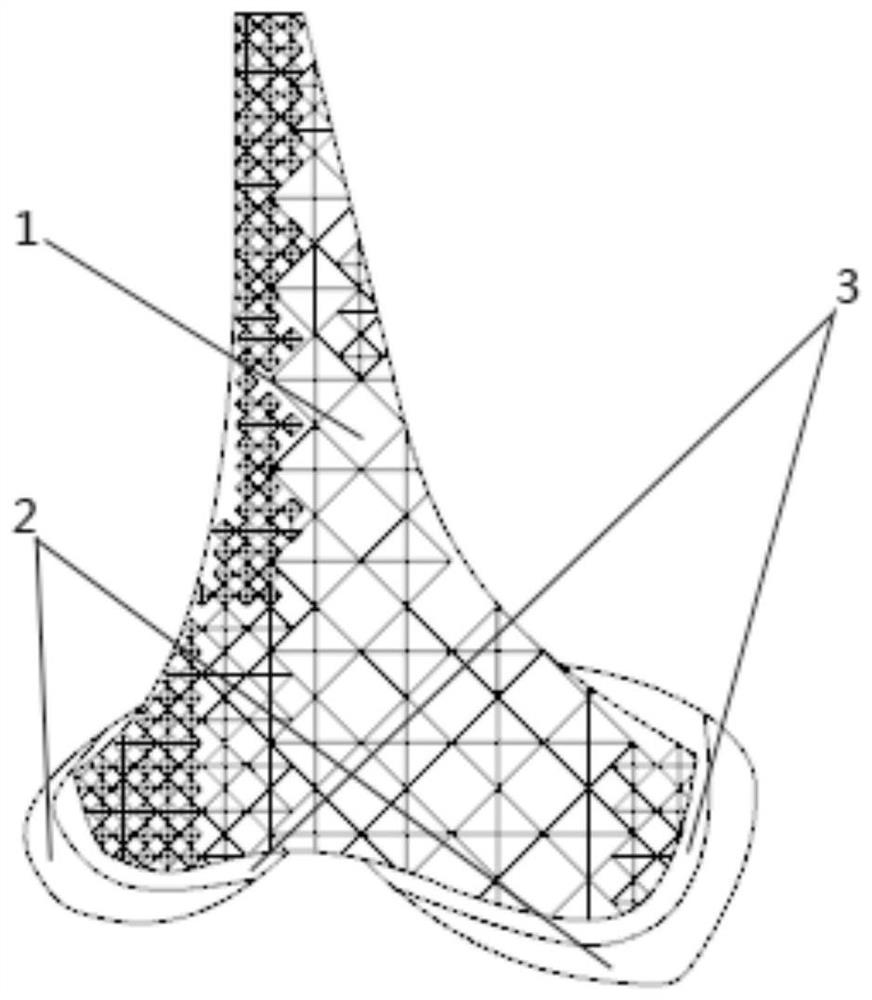

[0043] Such as figure 1 As shown, the present invention, a multi-material porous distal femur implant, includes a hard gradient porous distal femur implanted in the trunk 1 and soft hydrogel cartilage, and the hard gradient porous distal femur is implanted in the trunk 1 is a porous structure, and the outer contour is divided into a conical femoral body and two spherical imitation femoral ankles; the soft hydrogel cartilage is two semi-circular coverings, which are butterfly-shaped as a whole, and are respectively covered on the The two imitation femoral ankles; the hard gradient porous distal femur is implanted into the trunk, mainly as a bionic femur implanted into the patient's distal femur, and its surface is covered with microporous oxidation through micro-arc oxidation. Titanium and calcium hydroxyphosphate coating can effectively stimulate cells to attach to the surface of the implant, reduce the possibility of bacteria attaching to the surface of the implant, and avoid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com