Capacitor aluminum shell automatic production line processing technology

An automated production line and processing technology, applied in capacitors, electrical components, etc., can solve problems such as difficulty in meeting the explosion-proof level of aluminum shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

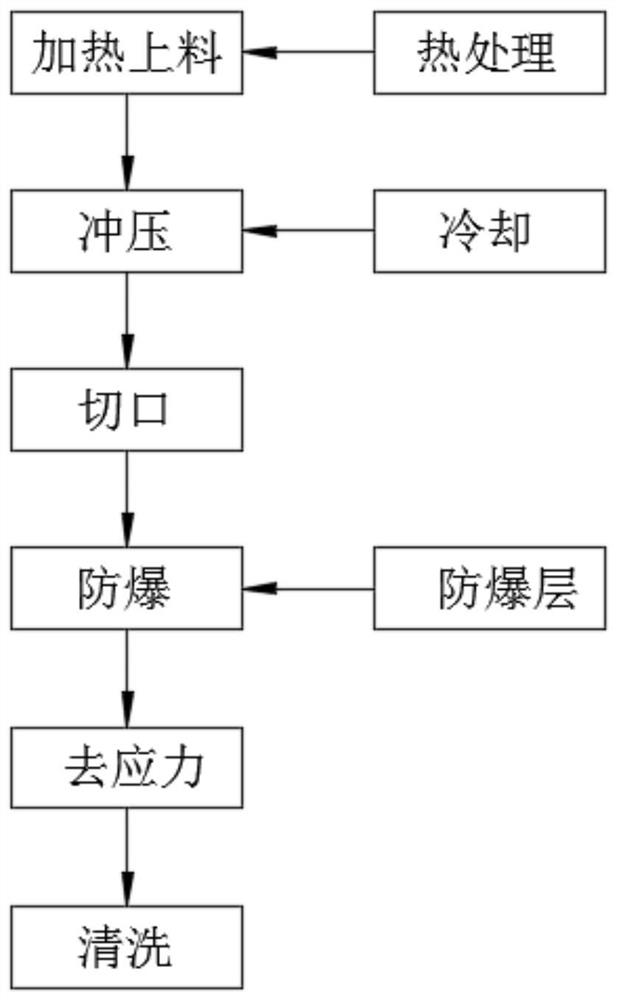

[0028] see figure 1 , an automatic production line processing technology for aluminum shells of capacitors, including the following steps: Step 1, heating and feeding, when the aluminum shell blanks are heated to 200-230 degrees Celsius in a heat treatment furnace, they are taken out and placed on a tray to stand empty for 1-2 minutes. The method can reduce the stamping force in the stamping process, and at the same time reduce the stress caused by deformation in the aluminum shell;

[0029] Step 2. Stamping. Use stamping equipment to stamp the aluminum shell blank in step 1 once, and hold the pressure for 2-3 minutes, then perform contact cooling with normal temperature water, and continue for 0.5-1min, demould and discharge, hold the pressure and Cooling can accelerate the shaping of the aluminum shell;

[0030] Step 3, cutting, cutting the semi-finished aluminum shell blank formed in step 2, removing excess material at the mouth, and polishing;

[0031] Step 4. Explosion-...

Embodiment 2

[0035] see figure 1 , an automatic production line processing technology for aluminum shells of capacitors, including the following steps: Step 1, heating and feeding, when the aluminum shell blanks are heated to 200 degrees Celsius in a heat treatment furnace, they are taken out and placed in a tray for 1 minute. This method can reduce Stamping force in the stamping process, while reducing the stress caused by deformation in the aluminum shell, shortening the processing time;

[0036] Step 2. Stamping. The stamping operation is carried out at a room temperature of 23-30 degrees Celsius. The stamping equipment performs a stamping of the aluminum shell blank in step 1, and keeps the pressure for 2 minutes, and then conducts normal temperature water contact cooling for 0.5 minutes. , demoulding and discharging, maintaining pressure and cooling, which can speed up the shaping of the aluminum shell and shorten the processing time; step 3, incision, cut the semi-finished aluminum s...

Embodiment 3

[0041] see figure 1 , a capacitor aluminum shell automatic production line processing technology, comprising the following steps: step 1, heating and feeding, when the aluminum shell blank is heated to 200 degrees Celsius in a heat treatment furnace, it is taken out and placed in a tray to stand empty for 1 minute;

[0042] Step 2. Stamping. The stamping operation is carried out at a room temperature of 23-30 degrees Celsius. The stamping equipment performs a stamping of the aluminum shell blank in step 1, and keeps the pressure for 2 minutes, and then conducts normal temperature water contact cooling for 0.5 minutes. , demoulding and discharging, maintaining pressure and cooling, which can speed up the shaping of the aluminum shell and improve processing efficiency; step 3, incision, cut the semi-finished aluminum shell billet formed in step 2, remove the excess material at the mouth, and polish it ;

[0043] Step 4. Explosion-proof. The aluminum shell formed in step 3 is em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com