Vesicle centrifugal protective agent, application of protective agent and method for centrifugally extracting vesicles

A protective agent and vesicle technology, applied in the field of centrifugal extraction of vesicles and vesicle centrifugal protective agent, can solve the problems of low separation efficiency and yield of cell vesicles, and improve the yield and separation efficiency of vesicles, and the volume change The effect of small degree and shortening of extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

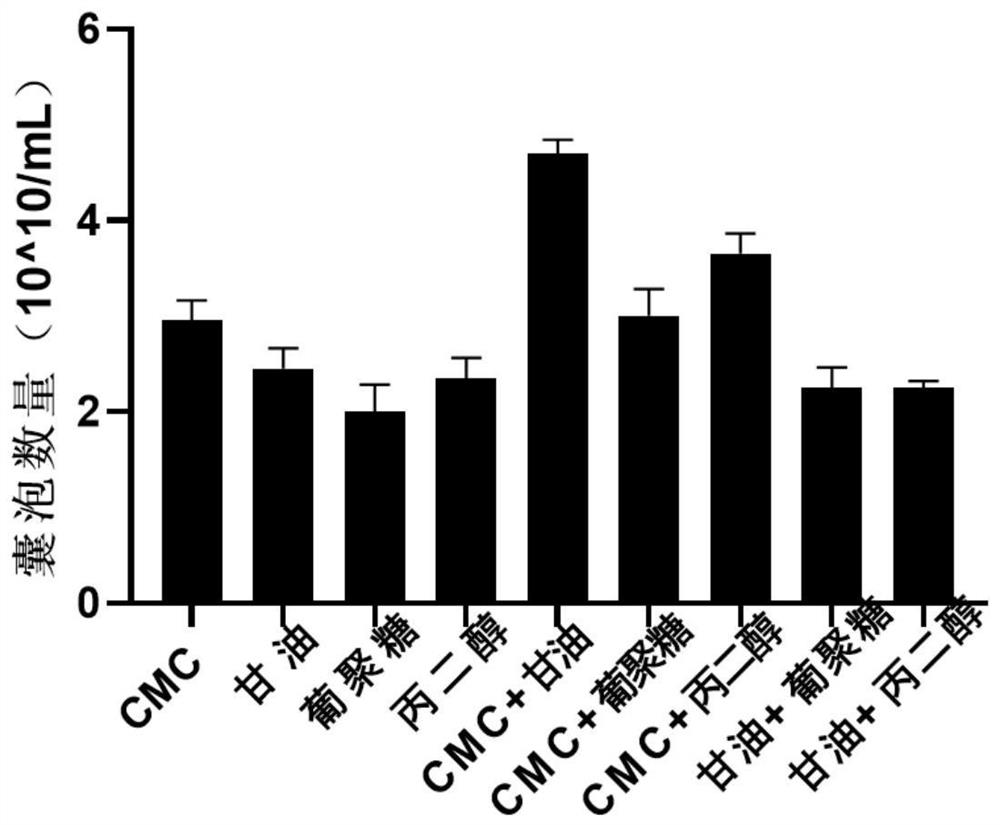

[0058] Example 1 Glycerin and sodium carboxymethyl cellulose are used in combination as a vesicle centrifugal protector

[0059] Preparation of cell suspension containing cell vesicles: Inoculate purified tumor cells in RPMI 1640 medium containing 10% fetal bovine serum (v / v), 100 U / mL penicillin, 100 mg / mL streptomycin, Place the medium inoculated with tumor cells in a carbon dioxide incubator at a temperature of 37°C and a gas atmosphere of 5% CO 2 cultured under the conditions until the cell concentration reached 2×10 7 cells / mL, then collect tumor cells and transfer them to a culture dish containing fresh medium, place the culture dish under ultraviolet radiation for 1 hour to induce cell apoptosis, and then culture in a carbon dioxide incubator for 16-20 hours to form stable cell vesicles , to obtain a cell suspension containing cell vesicles.

[0060] Differential centrifugation: The cell suspension containing cell vesicles is subjected to differential centrifugation t...

Embodiment 2

[0066] The optimization of embodiment 2 carboxymethyl cellulose sodium concentration

[0067]The cell suspension was prepared by the method of Example 1, and then the cell suspension was divided into different groups. First, 5% wt of glycerol was added, and then 0.25%, 0.5%, 1%, 2%, 4%, and 8% were added to each group respectively. %wt of sodium carboxymethylcellulose, mixed to obtain a suspension; the suspension was subjected to differential centrifugation according to step S2 of Example 1, and the cell vesicles obtained by differential centrifugation were analyzed using Malvern NS300 particle tracking The instrument was used to characterize the number of cell vesicles, and the characterization results are shown in figure 2 .

[0068] Depend on figure 2 It can be seen that the vesicle production depends on the concentration of sodium carboxymethyl cellulose within a certain range. As the concentration of sodium carboxymethyl cellulose increases, the number of cell vesicle...

Embodiment 3

[0069] The optimization of embodiment 3 glycerol concentration

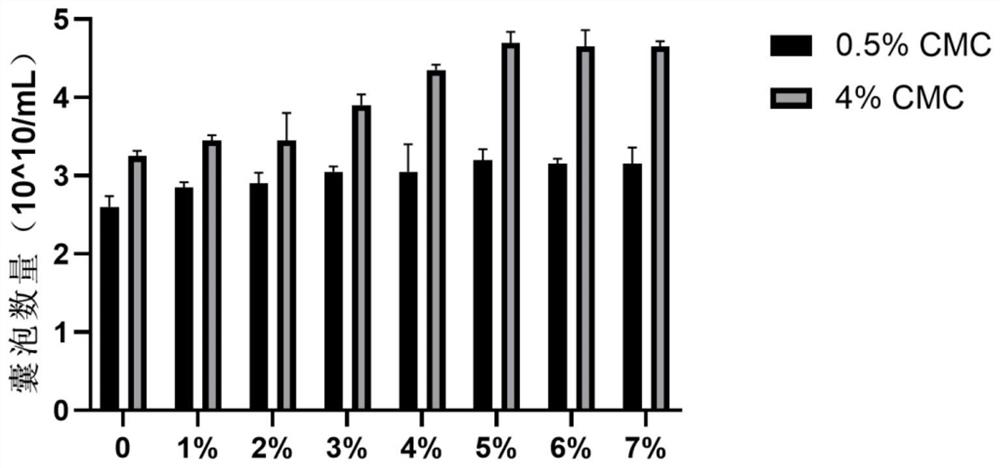

[0070] Adopt the method for embodiment 1 to prepare cell suspension, cell suspension is divided into two big groups afterwards, every big group is divided into different subgroups again, and two big groups add the sodium carboxymethyl cellulose of 0.5%wt and 4%wt earlier respectively, Afterwards, each group added 0, 1%, 2%, 3%, 4%, 5%, 6%, 7% wt of glycerin and mixed to obtain a suspension; the suspension was prepared according to step S2 of Example 1 Perform differential centrifugation, and use the Malvern NS300 particle tracking analyzer to characterize the number of cell vesicles obtained by differential centrifugation. The characterization results are shown in image 3 .

[0071] Depend on image 3 It can be seen that glycerol within a certain concentration range can improve the protective effect of carboxymethylcellulose sodium on cell vesicles. During high-speed centrifugation, the appropriate concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com