Aluminum electrolytic capacitor for gallium nitride charger and preparation method of aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and chargers, applied in the field of capacitors, can solve the problems of general lightning resistance and surge resistance, aluminum electrolytic capacitors breakdown, capacitor life failure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

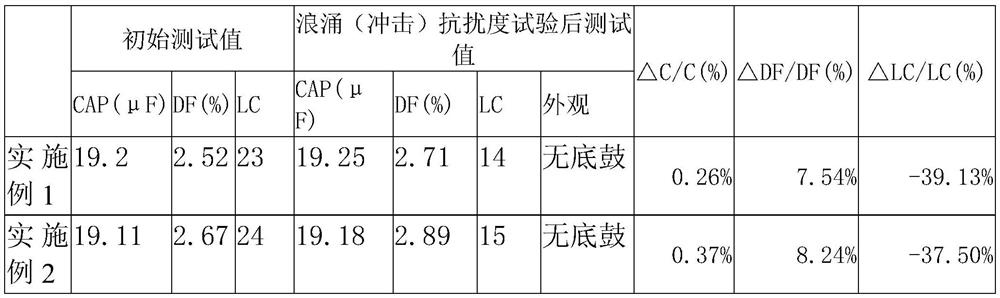

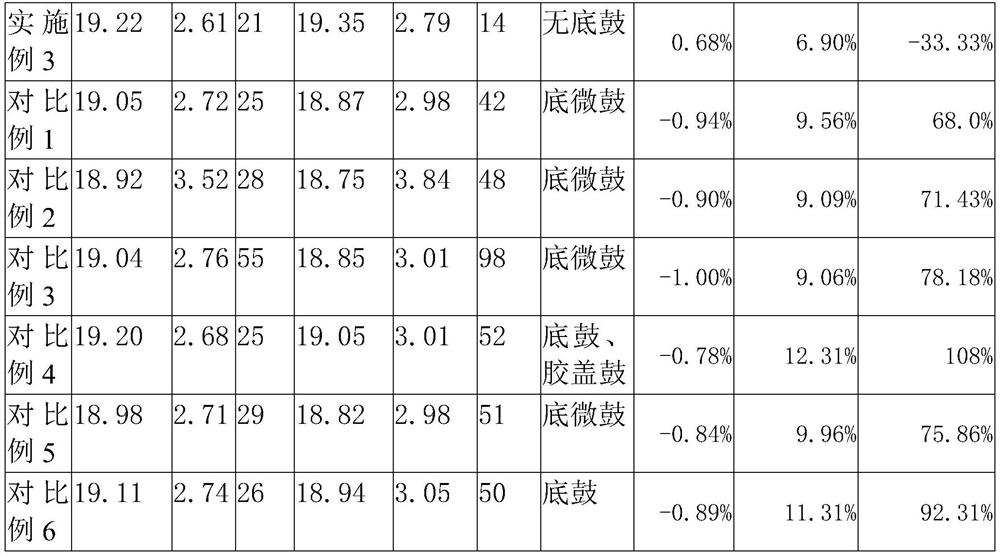

Examples

Embodiment 1

[0033] A preparation method for an aluminum electrolytic capacitor for a gallium nitride charger, comprising the following steps:

[0034] (1) Element winding: insert electrolytic paper between the anode foil and the cathode foil, and wind it into elements;

[0035] (2) Electrolyte solution impregnation: before immersing in the electrolyte solution, the element in step (1) is baked, then immersed in the electrolyte solution for impregnation treatment, and the electrolyte solution is composed of the following components by weight percentage: solvent 52%, solute 40%, additives 8%; among them,

[0036] The solvent is composed of the following components by weight percentage: ethylene glycol 38%, diethylene glycol 30%, phosphate 25%, nitrophenol 5%, citric acid 2%;

[0037] The solute is composed of the following components by weight percentage: 36% of long-chain carboxylic acid ammonium salt, 20% of succinic acid, 25% of sebacic acid, 12% of adipic acid, 2% of triethylamine salt...

Embodiment 2

[0042] A preparation method for an aluminum electrolytic capacitor for a gallium nitride charger, comprising the following steps:

[0043] (1) Element winding: insert electrolytic paper between the anode foil and the cathode foil, and wind it into elements;

[0044] (2) Electrolyte impregnation: before immersing in the electrolyte, the element in step (1) is baked, and then impregnated. The electrolyte is composed of the following components by weight percentage: solvent 45%, solute 50%, additive 5 %;in,

[0045] The solvent is composed of the following components by weight percentage: ethylene glycol 45%, diethylene glycol 25%, phosphate 16.5%, nitrophenol 10%, citric acid 3.5%;

[0046] The solute is composed of the following components by weight percentage: 30% of long-chain carboxylic acid ammonium salt, 38% of succinic acid, 20% of sebacic acid, 10.2% of adipic acid, 1% of triethylamine salt, 0.8% of polyglycerol %;

[0047] The additive is composed of the following co...

Embodiment 3

[0051] A preparation method for an aluminum electrolytic capacitor for a gallium nitride charger, comprising the following steps:

[0052] (1) Element winding: insert electrolytic paper between the anode foil and the cathode foil, and wind it into elements;

[0053] (2) Electrolyte solution impregnation: before immersing in the electrolyte solution, the element in step (1) is baked and then impregnated. The electrolyte solution is composed of the following components by weight percentage: 60% solvent, 30% solute, and 10% additive. %;in,

[0054] The solvent is composed of the following components by weight percentage: ethylene glycol 30%, diethylene glycol 40%, phosphate 23.5%, nitrophenol 5%, citric acid 1.5%;

[0055] The solute is composed of the following components by weight percentage: 48% of long-chain carboxylic acid ammonium salt, 10% of succinic acid, 28% of sebacic acid, 10% of adipic acid, 1.2% of triethylamine salt, 2.8% of polyglycerol %;

[0056] The additive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com