Zeolite-like zinc-based imidazolate metal organic framework steel bar corrosion inhibitor as well as preparation method and application thereof

A metal-organic framework and zinc-based imidazolate technology, which is applied in the field of reinforced concrete rust inhibitors, can solve the problems of low efficiency of rust inhibition, performance toxicity of concrete materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

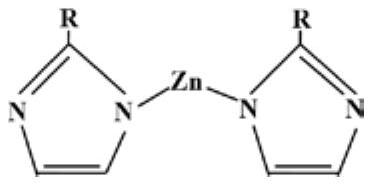

[0034] In two beakers, 5.95g zinc nitrate was dissolved in 46ml deionized water, 114.8g 2-methylimidazole was dissolved in 400mL deionized water, then the zinc nitrate solution was dripped into the 2-methylimidazole solution drop by drop, and Continue to stir and react at 25°C for 24 hours, then place the above mixed solution in a high-speed centrifuge and centrifuge at 10,000rpm for 10 minutes, and finally wash the product 3 times with the corresponding solvent and dry it in a vacuum oven at 105°C for 8 hours. After taking it out, it is fully ground to obtain a powdery zeolite zinc-based imidazolate MOFs rust inhibitor.

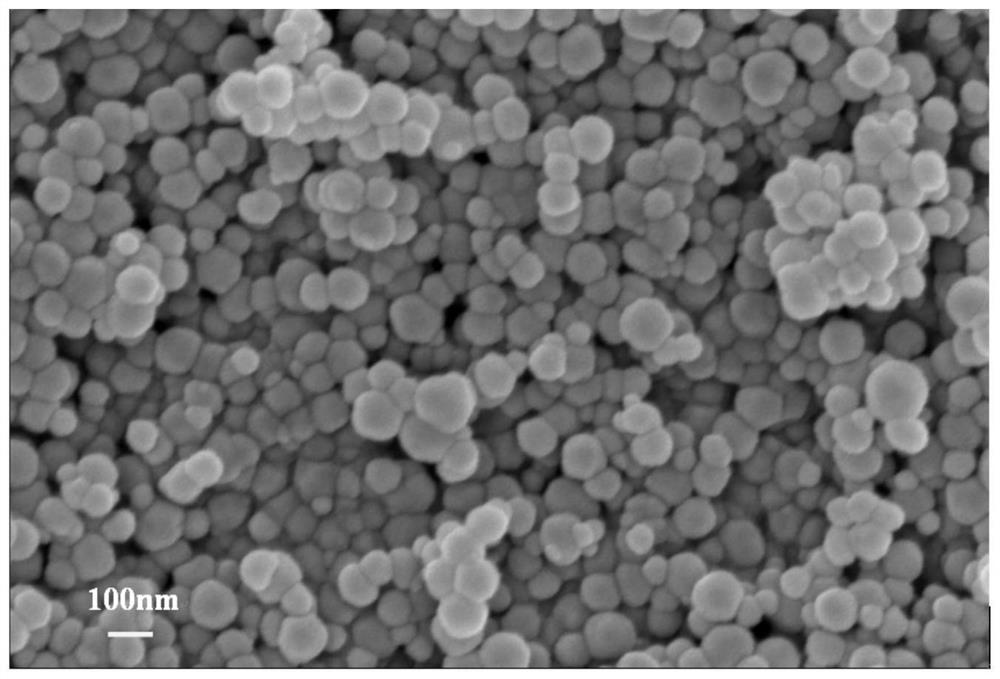

[0035] figure 1 The scanning electron microscope morphology of the zeolite zinc-based imidazolate MOFs steel bar rust inhibitor prepared according to the above steps, and its particle size ranges from 80 to 120 nm.

[0036] Performance evaluation of rust inhibitor:

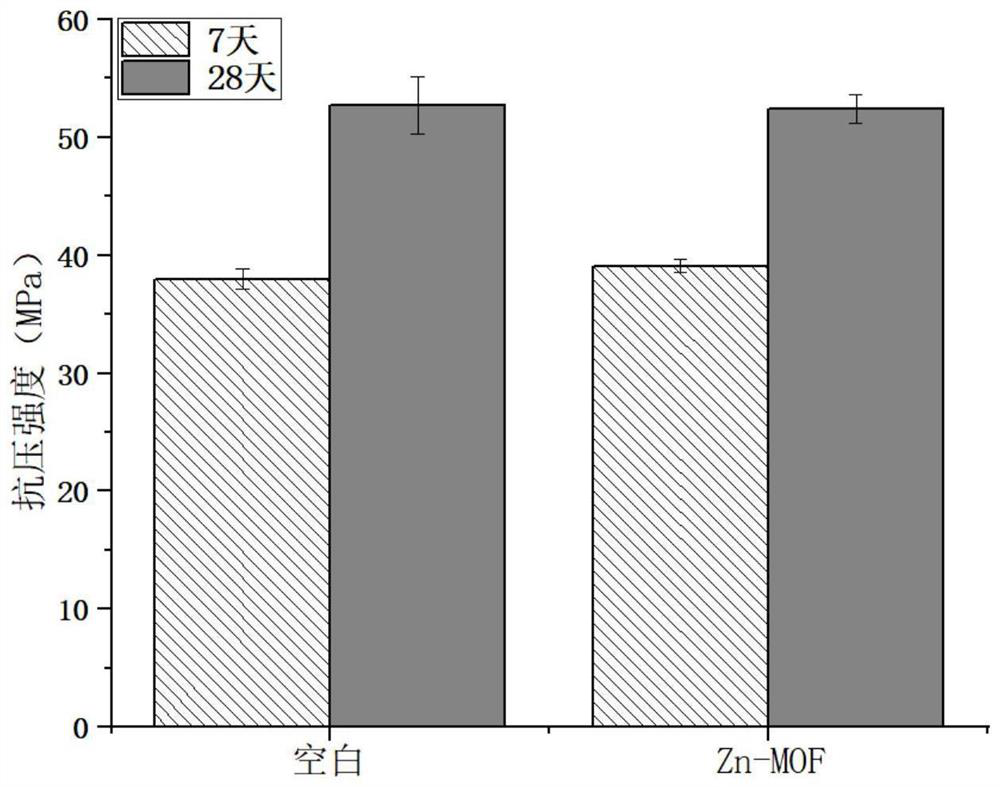

[0037] The present invention adopts the AC impedance spectrum electrochemical method to ca...

Embodiment 2

[0044] In this embodiment, except for the following features, all the other features are the same as in Embodiment 1;

[0045] During the preparation of zeolite zinc-based imidazolate MOFs rust inhibitor, the molar ratio of zinc ions to 2-nitroimidazole satisfies 1:60; before the reaction starts, the concentration of zinc ions in the solution system is controlled to be 0.05mol / L; After mixing, the stirring reaction was continued for 25 hours.

[0046] The test result of this embodiment is similar to that of embodiment 1.

Embodiment 3

[0048] In this embodiment, except the following features, all the other features are the same as in Embodiment 1;

[0049] During the preparation process of zeolite zinc-based imidazolate MOFs rust inhibitor, the molar ratio of zinc ions to 2-formyl imidazole satisfies 1:80; before the reaction starts, the concentration of zinc ions in the solution system is controlled to be 0.04mol / L; After mixing, the stirring reaction was continued for 23 hours.

[0050] The test result of this embodiment is similar to that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com