Water-based heavy anti-corrosion coating containing water-based modified chlorinated polyether emulsion and preparation method of coating

A water-based modification and water-containing technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor storage stability and high brittleness of heavy-duty anti-corrosion coatings, and achieve excellent impact resistance, strong adhesion, and long-lasting resistance to salt spray protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

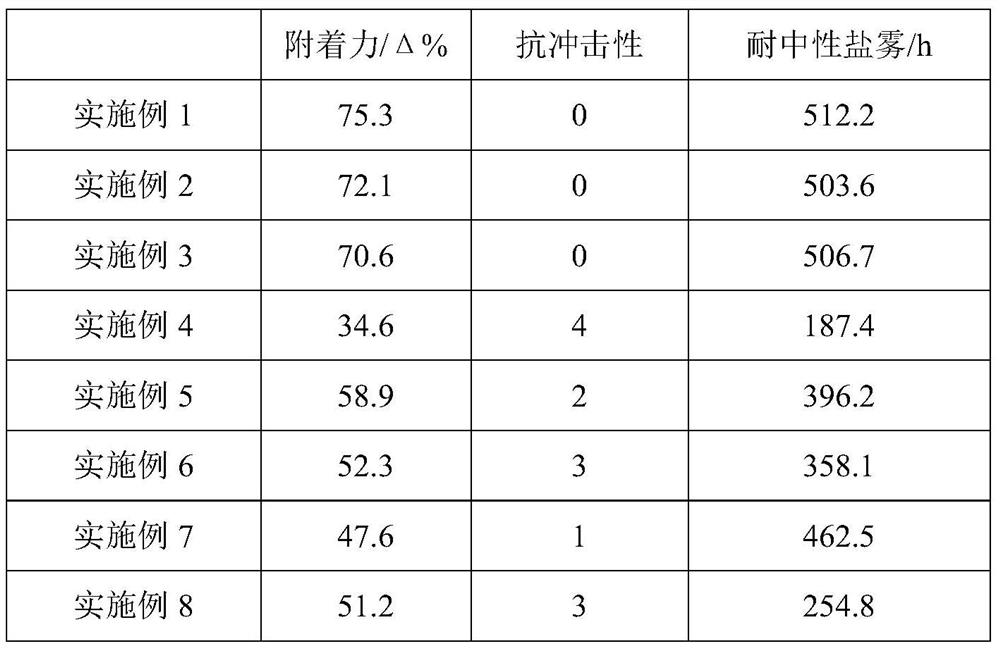

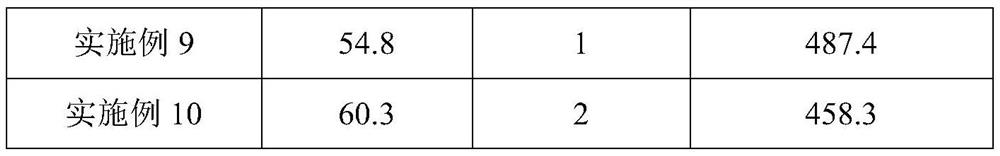

Examples

preparation example Construction

[0065] The second aspect of the present invention provides a method for preparing a water-based heavy-duty anti-corrosion coating containing a water-based modified chloroether emulsion. The specific preparation steps include:

[0066] S1. Prepare water-based modified chloroether emulsion;

[0067] S2. According to the formula quantity, add the water-based modified chloroether emulsion, wetting agent, defoamer, anti-settling agent, leveling agent, film-forming aid and water in the raw material of component A into the reaction vessel, and stir for 10- 15min, then add ultra-fine barium sulfate, mica powder, zinc phosphate, aluminum zinc orthophosphate, thickener, dispersant, anti-flash rust agent, filler and silicon micropowder, continue stirring for 10-15min, finally add grinding beads and continue stirring for 10 minutes -15min; keep the stirring speed at 2300-2800r / min during the stirring process, and keep the reaction vessel in a water bath at 15-30°C;

[0068] Pass the grou...

Embodiment 1

[0074] This embodiment provides a water-based heavy-duty anti-corrosion coating containing a water-based modified chlorinated ether emulsion, and its raw materials include, by weight percentage:

[0075] Component A: 56% water-based modified chlorine ether emulsion, 5.5% superfine barium sulfate, 4% mica powder, 4% zinc phosphate, 2% aluminum zinc orthophosphate, 0.3% thickener, 0.15% wetting agent, disinfectant 0.4% foaming agent, 0.2% dispersing agent, 0.03% anti-flash rust agent, 0.07% anti-settling agent, 0.07% leveling agent, 3% film-forming aid, 6% filler, 2% microsilica powder; water supplements the balance;

[0076] B component: curing agent 50%, water 50%.

[0077] The weight ratio of A component and B component is 1:1.3.

[0078] The water-based modified chloroether emulsion adopts acrylic compound to modify the chloroether emulsion. The raw materials include: in parts by weight, 20 parts of vinyl chloride, 7 parts of isobutyl vinyl ether, 1 part of acrylic compoun...

Embodiment 2

[0108] A water-based heavy-duty anti-corrosion coating containing a water-based modified chlorinated ether emulsion, the specific implementation is the same as in Example 1. The difference is that, by weight percentage, its raw materials include:

[0109] Component A: 52% water-based modified chlorine ether emulsion, 4% superfine barium sulfate, 3% mica powder, 2% zinc phosphate, 1% aluminum zinc orthophosphate, 0.1% thickener, 0.1% wetting agent, disinfectant 0.3% foaming agent, 0.1% dispersing agent, 0.01% anti-flash rust agent, 0.05% anti-settling agent, 0.1% leveling agent, 2% film-forming aid, 5% filler, 1% silica powder; water supplements the balance;

[0110] B component: curing agent 50%, water 50%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com