Preparation method of functional polycarboxylate-type water reducing agent for resisting flocculating agent in machine-made sand

A technology of polycarboxylic acid series and water reducing agent is applied in the field of functional polycarboxylic acid series water reducing agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

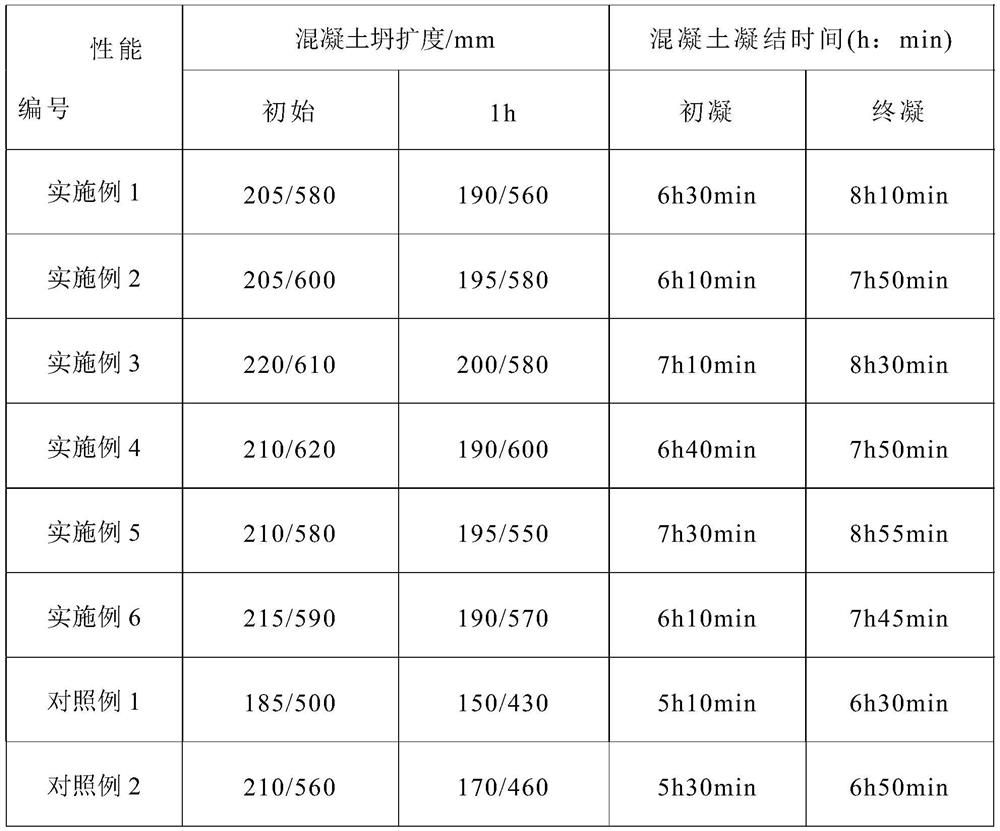

Examples

Embodiment 1

[0023] Dissolve 100g of N-chloromethylphthalimide in 420g of ethylene glycol ether, then add 3g of trimethylhydroxyethylethylenediamine and stir for 6 hours at 20°C to obtain o-phenylketene imine;

[0024] Then 8g o-phenylketeneimine and 3g carbonamide were mixed evenly and then added dropwise to 100g of polyethylene glycol monomethyl ether with bis-azido group in the molten state at 45°C in a molten state with a weight average molecular weight of 2000 and In 0.1g of trifluoroperacetic acid, carry out in-situ polymerization reaction, add dropwise for 2h, obtain in-situ polycarboxylate water reducer;

[0025] Finally, 100g of in-situ polycarboxylate water-reducer and 100g of chloroform were subjected to Delepine reaction at 60°C for 1 hour in a nitrogen gas of 0.2Mpa atmospheric pressure to obtain a functional polycarboxylate water-reducer.

Embodiment 2

[0027] Dissolve 100g of N-methylolphthalimide in 310g of propylene glycol ether, then add 5g of dimethylaminodiethyl ether and stir at 40°C for 3 hours to obtain o-phenylketeneimine;

[0028] Then mix 8.5g of o-phenylketeneimine and 4g of diethyl hydroxymalonate evenly, and then dropwise add 100g of end group-containing bis-azido polyethylene glycol with a weight-average molecular weight of 1000 in a molten state at 60°C to the reactor. Carry out in-situ polymerization reaction in glycol monomethyl ether and 0.13g peroxybenzoic acid, add dropwise for 2h, obtain in-situ polycarboxylate water reducer;

[0029] Finally, 100g of in-situ polycarboxylate-based water reducer and 108g of 1,2-dichloroethane were subjected to Delepine reaction at 70°C for 3h in nitrogen gas at 0.4Mpa atmospheric pressure to obtain a functional polycarboxylate-based water-reducer .

Embodiment 3

[0031] Dissolve 100g of N-chloromethylphthalimide in 380g of propylene glycol ethyl ether, then add 6g of dimethylaminodiethyl ether and stir for 4 hours at 35°C to obtain o-phenylketeneimine;

[0032] Then mix 10g of o-phenylketeneimine and 5.5g of diethyl aminomalonate evenly, and then dropwise add 100g of polyethylene glycol with a weight average molecular weight of 1200 in a molten state at 50°C to the reactor. Alcohol monomethyl ether and 0.15g trifluoroperacetic acid, carry out in-situ polymerization reaction, add dropwise for 3h, obtain in-situ polycarboxylate water reducer;

[0033] Finally, 100g of in-situ polycarboxylate water-reducer and 135g of methyl iodide were subjected to Delepine reaction at 65°C for 2h in nitrogen gas at an atmospheric pressure of 0.3Mpa to obtain a functional polycarboxylate water-reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com