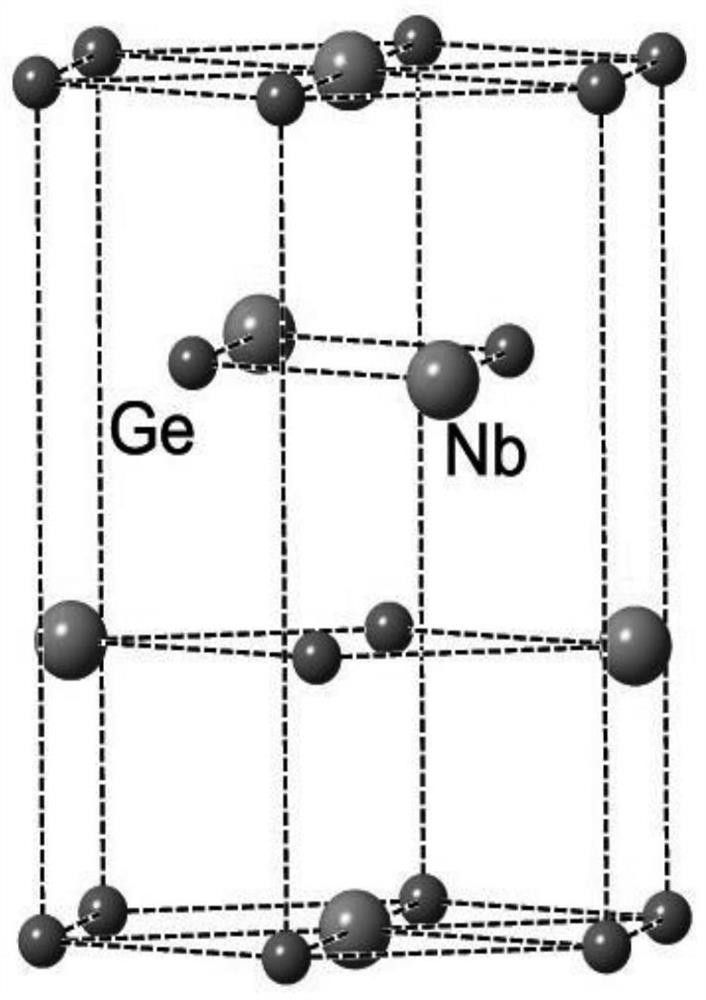

a nbge 2 Single crystal and its preparation method and application

A single crystal and single substance technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of complex preparation methods, research, low quality of single crystals, etc., to achieve broad application prospects, simple preparation methods, The effect of high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

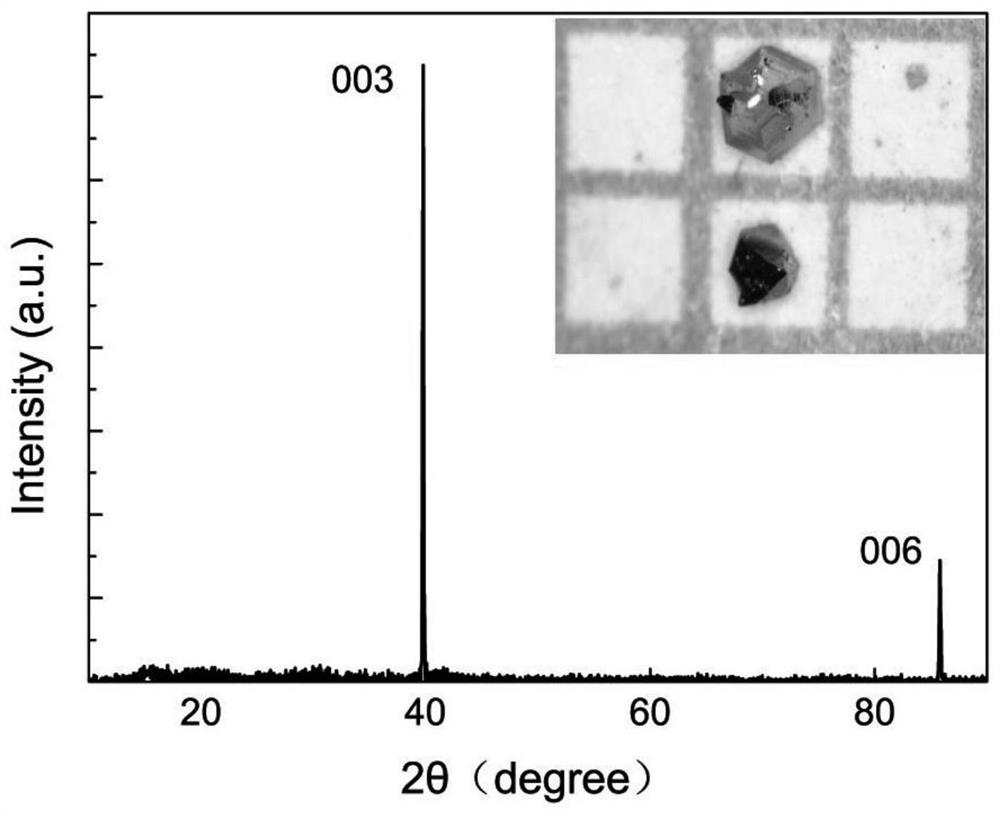

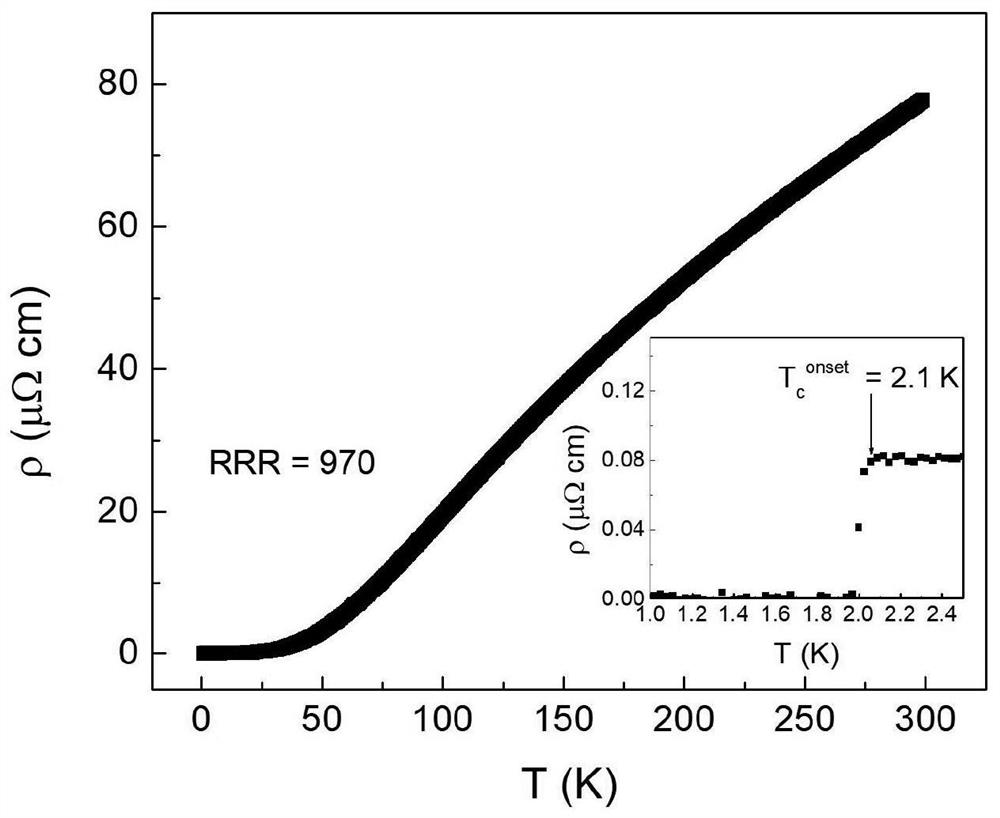

Embodiment 1

[0028] 1) Grinding Nb and Ge with a molar ratio of 1:2 in a glove box in an argon atmosphere for 20 min to obtain a mixed powder;

[0029]2) Put the above mixed powder in an alumina corundum sleeve, then seal the corundum in a evacuated quartz tube, and then put it into a box furnace to raise the temperature to 1073K at a heating rate of 2K / min. Calcined for 2 days;

[0030] 3) re-grind the calcined mixed powder in a glove box in an argon atmosphere, and grind it at 2 mg / cm 3 Add the appropriate concentration of I 2 , and encapsulate it in a 16cm vacuum glass tube, transport it for a week under the temperature difference of 1073K at the high temperature end and 973K at the low temperature end, and finally obtain NbGe at the cold end 2 single crystal.

Embodiment 2

[0032] 1) Grinding Nb and Ge with a molar ratio of 1:2 in a glove box in an argon atmosphere for 20 min to obtain a mixed powder;

[0033] 2) Put the above mixed powder in an alumina corundum sleeve, then seal the corundum in a evacuated quartz tube, and then put it into a box furnace to raise the temperature to 1173K at a heating rate of 3K / min. Calcined for 4 days;

[0034] 3) re-grind the calcined mixed powder in a glove box in an argon atmosphere, and grind it at 2 mg / cm 3 Add the appropriate concentration of I 2 , and encapsulate it in a 16cm vacuum glass tube, transport it for a week under the temperature difference of 1073K at the high temperature end and 973K at the low temperature end, and finally obtain NbGe at the cold end 2 single crystal.

Embodiment 3

[0036] 1) Grinding Nb and Ge with a molar ratio of 1:2 in a glove box in an argon atmosphere for 30min to obtain a mixed powder;

[0037] 2) Put the above mixed powder in an alumina corundum sleeve, then seal the corundum in a evacuated quartz tube, and then put it into a box furnace to raise the temperature to 1173K at a heating rate of 3K / min. Calcined for 4 days;

[0038] 3) re-grind the calcined mixed powder in a glove box in an argon atmosphere, and grind it at 2 mg / cm 3 Add the appropriate concentration of I 2 , and encapsulate it in a 16cm vacuum glass tube, transport it for a week under the temperature difference of 1073K at the high temperature end and 1023K at the low temperature end, and finally obtain NbGe at the cold end 2 single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com