Halogen-free flame-retardant high-toughness ABS resin composition containing nanoscale flame retardant and preparation method thereof

An ABS resin, nano-level technology, applied in the field of polymer material processing, can solve the problems of difficulty in dispersion, poor compatibility of flame retardants, and difficulty in maintaining ABS performance in a balanced manner, and achieves stable processing, low cost, and good comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

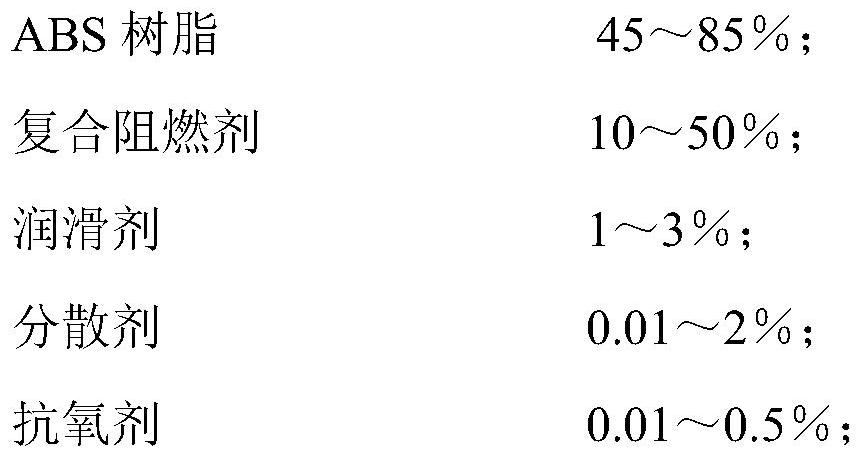

[0027] A halogen-free flame-retardant high-toughness ABS resin composition containing a nano-scale flame retardant, which is prepared from the following components and raw materials in parts by weight:

[0028]

[0029] The flame retardant in the composite flame retardant is phosphaphenanthrene oxide grafted modified aluminum hydroxide with a particle size of 20-50nm, the effective content of the flame retardant is controlled to 10%, the lubricant is stearic acid, and the dispersant is anhydrous Ethanol, antioxidants are 1010, 1076; put ABS, composite flame retardant, lubricant, and antioxidant into the high-speed mixer in proportion, and mix thoroughly for 1 to 10 minutes; send the materials into the In a twin-screw extruder of 20°C, extrude and granulate in the range of 150-250°C to obtain the halogen-free flame-retardant high-toughness ABS resin containing nano-scale flame retardant.

Embodiment 2

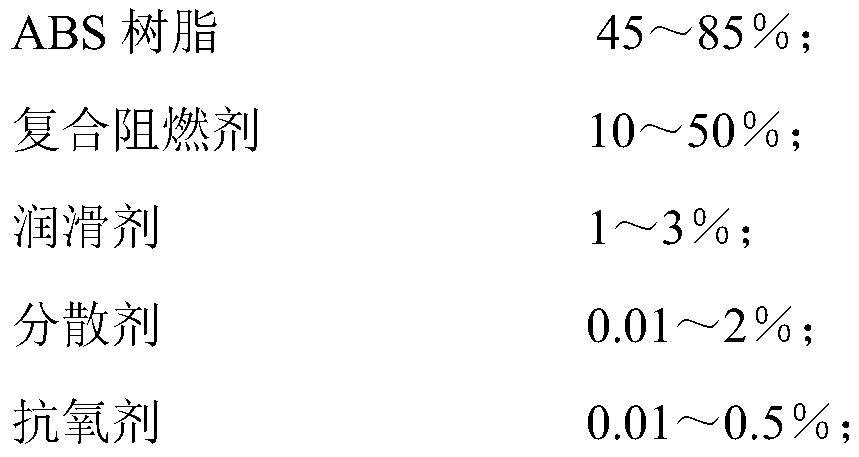

[0031] A halogen-free flame-retardant high-toughness ABS resin composition containing a nano-scale flame retardant, which is prepared from the following components and raw materials in parts by weight:

[0032]

[0033] The flame retardant in the composite flame retardant is phosphaphenanthrene oxide grafted modified aluminum hydroxide with a particle size of 20-50nm, the effective content of the flame retardant is controlled to 10%, the lubricant is stearic acid, and the dispersant is anhydrous Ethanol, antioxidants are 1010, 1076; put ABS, composite flame retardant, lubricant, and antioxidant into the high-speed mixer in proportion, and mix thoroughly for 1 to 10 minutes; send the materials into the In a twin-screw extruder of 20°C, extrude and granulate in the range of 150-250°C to obtain the halogen-free flame-retardant high-toughness ABS resin containing nano-scale flame retardant. .

Embodiment 3

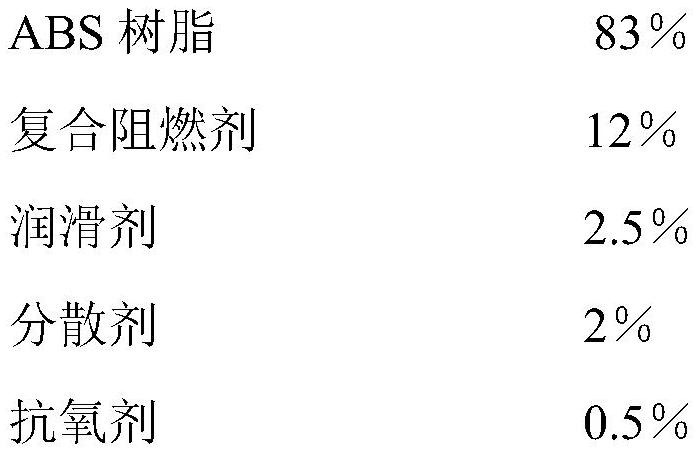

[0035] A halogen-free flame-retardant high-toughness ABS resin composition containing a nano-scale flame retardant, which is prepared from the following components and raw materials in parts by weight:

[0036]

[0037] The flame retardant in the composite flame retardant is phosphaphenanthrene oxide grafted modified aluminum hydroxide with a particle size of 20-50nm, the effective content of the flame retardant is controlled to 10%, the lubricant is stearic acid, and the dispersant is anhydrous Ethanol, antioxidants are 1010, 1076; put ABS, composite flame retardant, lubricant, and antioxidant into the high-speed mixer in proportion, and mix thoroughly for 1 to 10 minutes; send the materials into the In a twin-screw extruder of 20°C, extrude and granulate in the range of 150-250°C to obtain the halogen-free flame-retardant high-toughness ABS resin containing nano-scale flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com