Polylactic acid melt reinforcing agent and preparation method thereof

A technology of melt enhancer and polylactic acid, which is applied in the field of melt enhancer and its preparation for blow molding of polylactic acid, can solve the problems of easy migration and the compatibility of polylactic acid needs to be improved, and achieve simple and good formula The prospect of industrialized production, the effect of adding less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

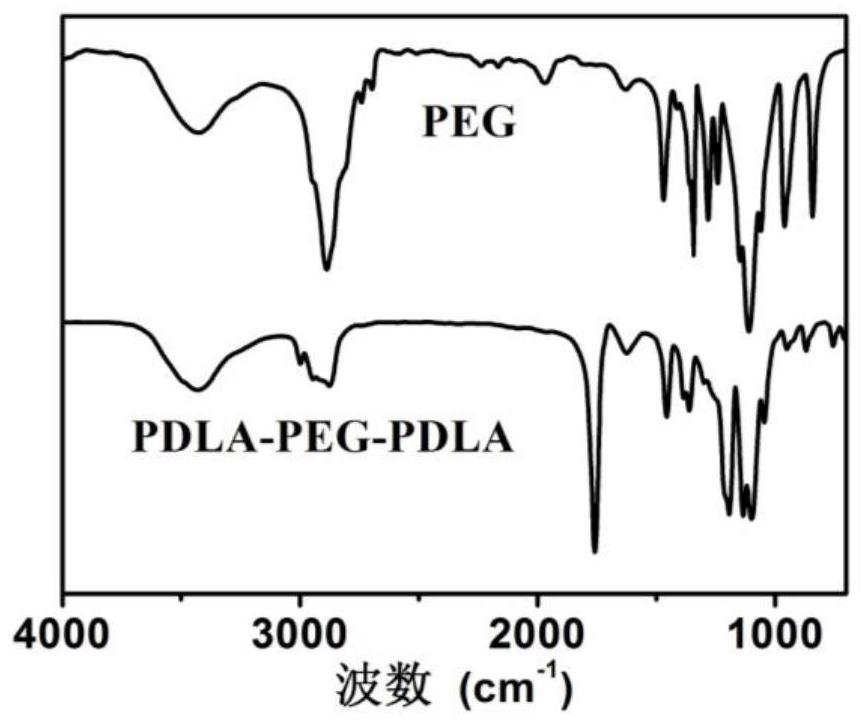

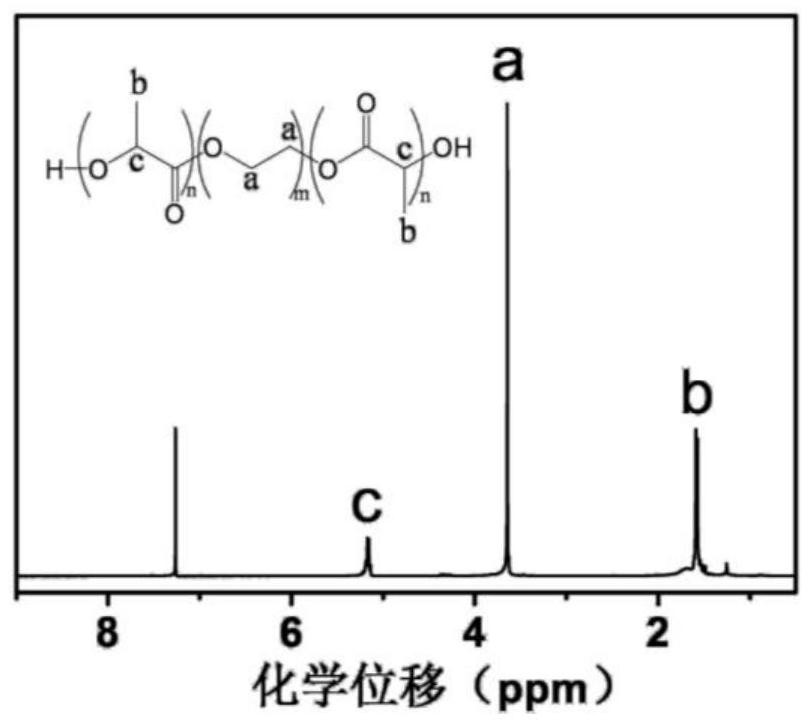

[0032] A polylactic acid melt enhancer provided by the present invention and its preparation method, the preparation process is as follows: 100 parts of D-LA and 125 parts of PEG10000 (Mn=10000) are fed nitrogen into the reactor, heated to 150 ° C and melted After 30 minutes, add 0.5 parts of stannous octoate catalyst, keep the nitrogen atmosphere and continue to stir the reaction for 18 hours. After the reaction is completed, the solid obtained is a block copolymer PDLA- PEG-PDLA.

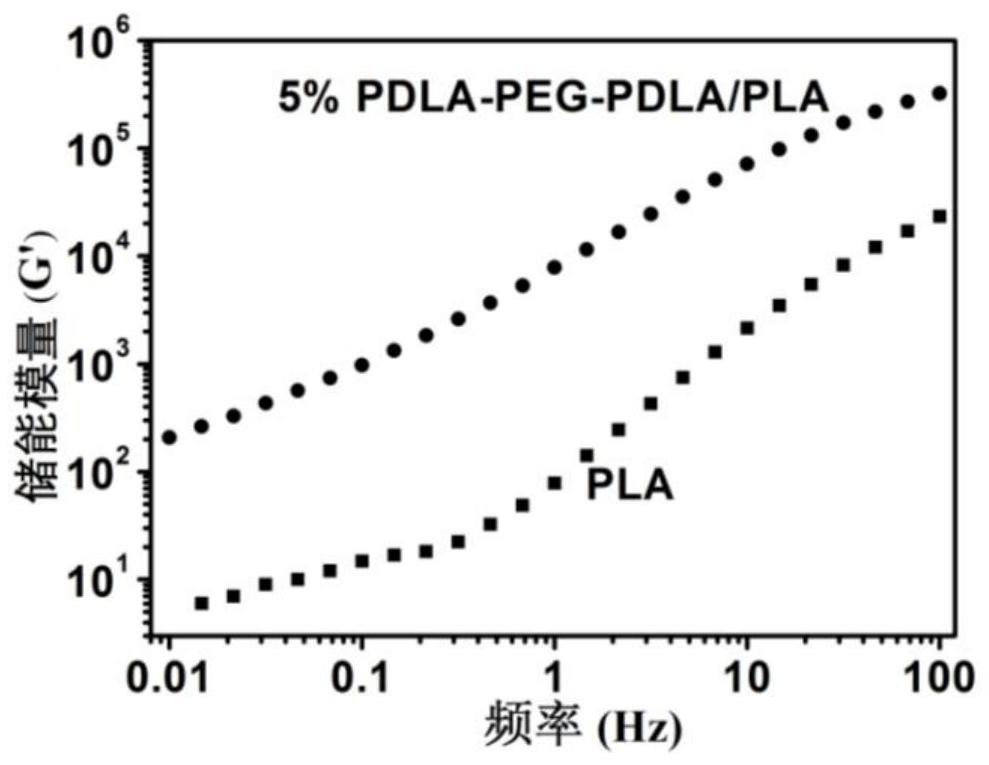

[0033] Take 5 parts of the prepared PDLA-PEG-PDLA and add it to the polylactic acid matrix for melt blending, and blend at 175°C for 5 minutes to obtain a composite material. The preferred number of parts of the polylactic acid matrix is 250-20 parts.

Embodiment 2

[0035] A polylactic acid melt enhancer provided by the present invention and its preparation method, the preparation process is: feed 100 parts of D-LA and 25 parts of PEG2000 (Mn=2000) into a reaction kettle with nitrogen, heat to 150°C and melt After 30 minutes, add 0.5 parts of stannous octoate catalyst, keep the nitrogen atmosphere and continue to stir the reaction for 18 hours. After the reaction is completed, the solid obtained is a block copolymer PDLA- PEG-PDLA.

[0036] Take 5 parts of the prepared PDLA-PEG-PDLA and add it to the polylactic acid matrix for melt blending, and blend at 175°C for 5 minutes to obtain a composite material. The preferred number of parts of the polylactic acid matrix is 250-20 parts.

Embodiment 3

[0038] A polylactic acid melt enhancer provided by the present invention and its preparation method, the preparation process is as follows: 100 parts of D-LA and 50 parts of PEG4000 (Mn=4000) are fed nitrogen into the reactor, heated to 150 ° C and melted After 30 minutes, add 0.5 parts of stannous octoate catalyst, keep the nitrogen atmosphere and continue to stir the reaction for 18 hours. After the reaction is completed, the solid obtained is a block copolymer PDLA- PEG-PDLA.

[0039] Take 5 parts of the prepared PDLA-PEG-PDLA and add it to the polylactic acid matrix for melt blending, and blend at 175°C for 5 minutes to obtain a composite material. The preferred number of parts of the polylactic acid matrix is 250-20 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com