Method for preparing colon-targeted microcapsules by applying microfluid technology

A colon-targeting and microfluidic technology, which is applied in the preparation, application, and microcapsules of microspheres, can solve the problems of unfriendly bioactive proteins, long preparation process, easy inactivation and decomposition of proteins, etc., and achieve good biocompatibility and degradability, to achieve colon-specific release, to protect the structure and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

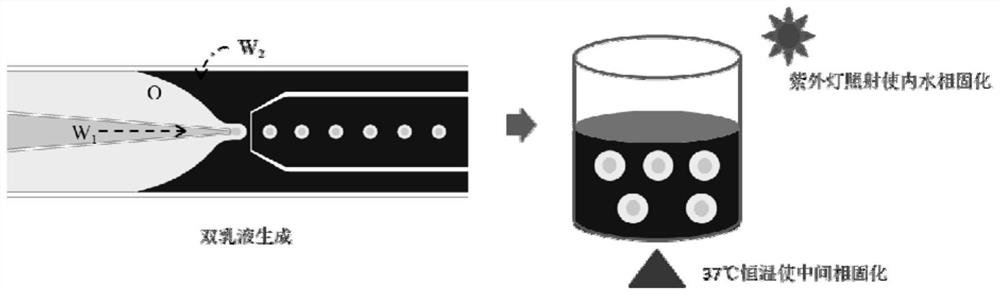

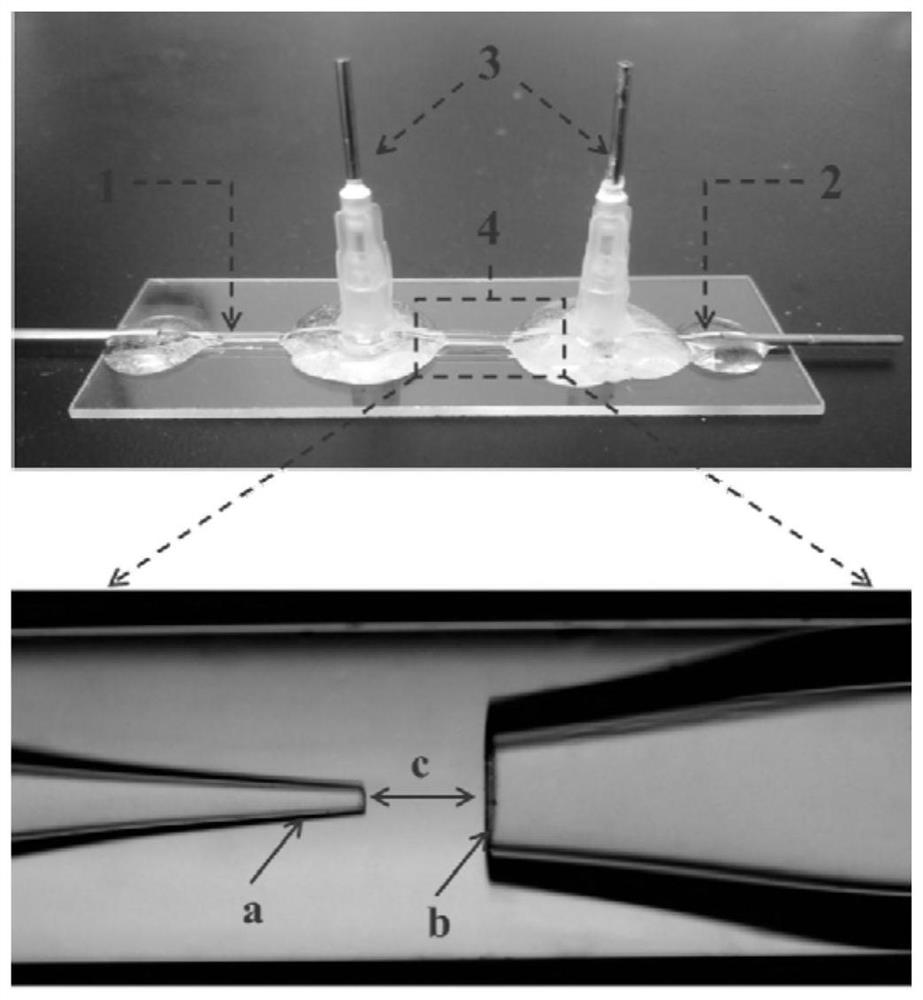

[0057] Example 1: Construction of a glass microfluidic device

[0058] The glass microfluidic device is a self-made one-step double-emulsion device, including an internal phase capillary, a collection tube, a square tube, and two injection needles; a capillary of appropriate length (outer diameter 960 μm, inner diameter 550 μm) was burnt and pulled into a Two capillaries with sharp ends were ground with a needle grinder until the tip diameters were 20-100 μm and 150-400 μm, respectively, as the internal phase capillary and the emulsion collection tube. Specifically, the tip diameter of the internal phase capillary is 60 μm, the tip diameter of the collection tube is 350 μm, the outer diameter of the square tube is 1.4 mm, and the inner diameter is 1.1 mm. The square tube is fixed at the center of the slide, and the tip of the internal phase capillary is inserted into the square tube. In the middle position, the other end of the internal phase liquid inlet capillary protrudes a...

Embodiment 2

[0059] Embodiment 2: Preparation and characterization of modified chitosan

[0060] (1) Preparation of modified chitosan

[0061] Weigh 1.0g of chitosan and place it in a 250mL round bottom flask, add 99mL of ultrapure water, add 1mL of acetic acid under magnetic stirring, until the chitosan is completely dissolved, add 1-5mL of 2-methacrylic anhydride solution, 60 ℃, 1000r / min reaction for 10h, the reaction solution was cooled to room temperature, and saturated Na 2 CO 3 Adjust the pH of the aqueous solution to 7.0, put the reaction solution into a 3.5K cellulose dialysis bag, dialyze for 72 hours in pure water to remove small molecular substances in the reaction solution, and finally freeze-dry the solution to obtain a white spongy substance, which is modified chitosan.

[0062] (2) Fourier transform infrared spectroscopic analysis

[0063] Using infrared spectroscopy to analyze the chemical structure of modified chitosan, 400~4000cm -1 The solid samples of modified and ...

Embodiment 3

[0070] Embodiment 3: the preparation of microcapsule

[0071] (1) Preparation of three-phase solution

[0072] The modified chitosan obtained in Example 2 is dissolved in 1% (v / v) aqueous acetic acid solution, stirred until completely dissolved, and the prepared concentration (w / v) is 1%, 1.5%, 2% (w / v ) modified chitosan aqueous solution. Then add 1mol / L NaOH solution dropwise in the modified chitosan aqueous solution, adjust the pH to 7.0, use bovine serum albumin as the model protein, add bovine serum albumin in the modified chitosan solution and stir until completely dissolved, The protein concentration (w / v) is 1%, 5%, 10%, 15%, then add 2-hydroxy-2-methyl propiophenone, the concentration is 0.1% (v / v), stir vigorously until the dispersion is even, static Place to remove air bubbles to obtain an internal phase aqueous solution containing protein and core material; add ethyl cellulose to dichloromethane, keep in a closed place in the dark until the ethyl cellulose is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com